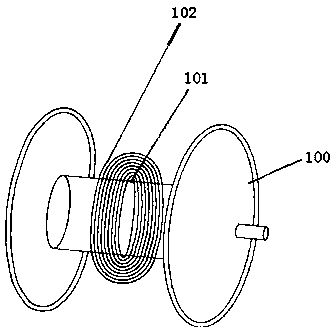

Double-groove parent-and-subsidiary type steel cable winding drum and steel cable winding method

A wire rope reel and wire rope technology, applied in hoisting devices, spring mechanisms, etc., can solve the problems of reduced safety factor and service life, low safety factor, low work efficiency, etc., shorten maintenance time and improve pouring quality , The effect of reducing the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

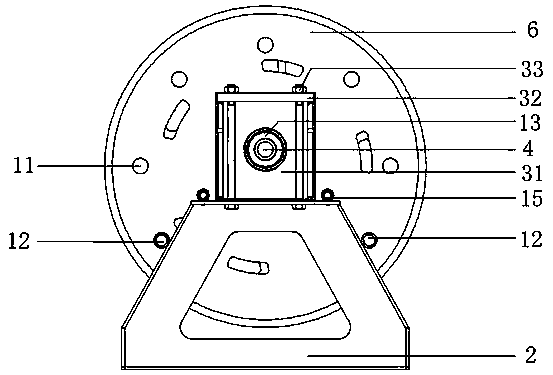

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] Please see attached figure 2 , a double-groove mother-in-female wire rope reel, including a frame seat 2, a reel support seat 3, a reel rotating shaft 4, a reel disc 6, a reel main groove 7, a groove plate sliding opening 8, and a reel auxiliary groove 9 and the reel isolation plate 10; the reel main groove 7 and the reel auxiliary groove 9 are respectively coaxially connected to both sides of the reel isolation plate 10, and the reel main groove 7 and the reel auxiliary groove 9 pass through the reel rotating shaft 4 Coaxially connected into an integrated reel body and rotate synchronously, the reel disk 6 is coaxially connected to both ends of the reel body to form a double-slot mother-in-one reel body; the reel disk 6 passes through the reel support seat 3 through the bolt It is fixedly installed on the frame seat 2, the groove plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com