Method for producing webs for reinforcement ply of a tyre by butt-joining of straight-wire strips

A technology of reinforced ply and straight curtain, which is applied in the manufacture of reinforced ply and the field of pneumatic tires, which can solve the problems of high complexity and cost, and achieve the effect of optimizing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

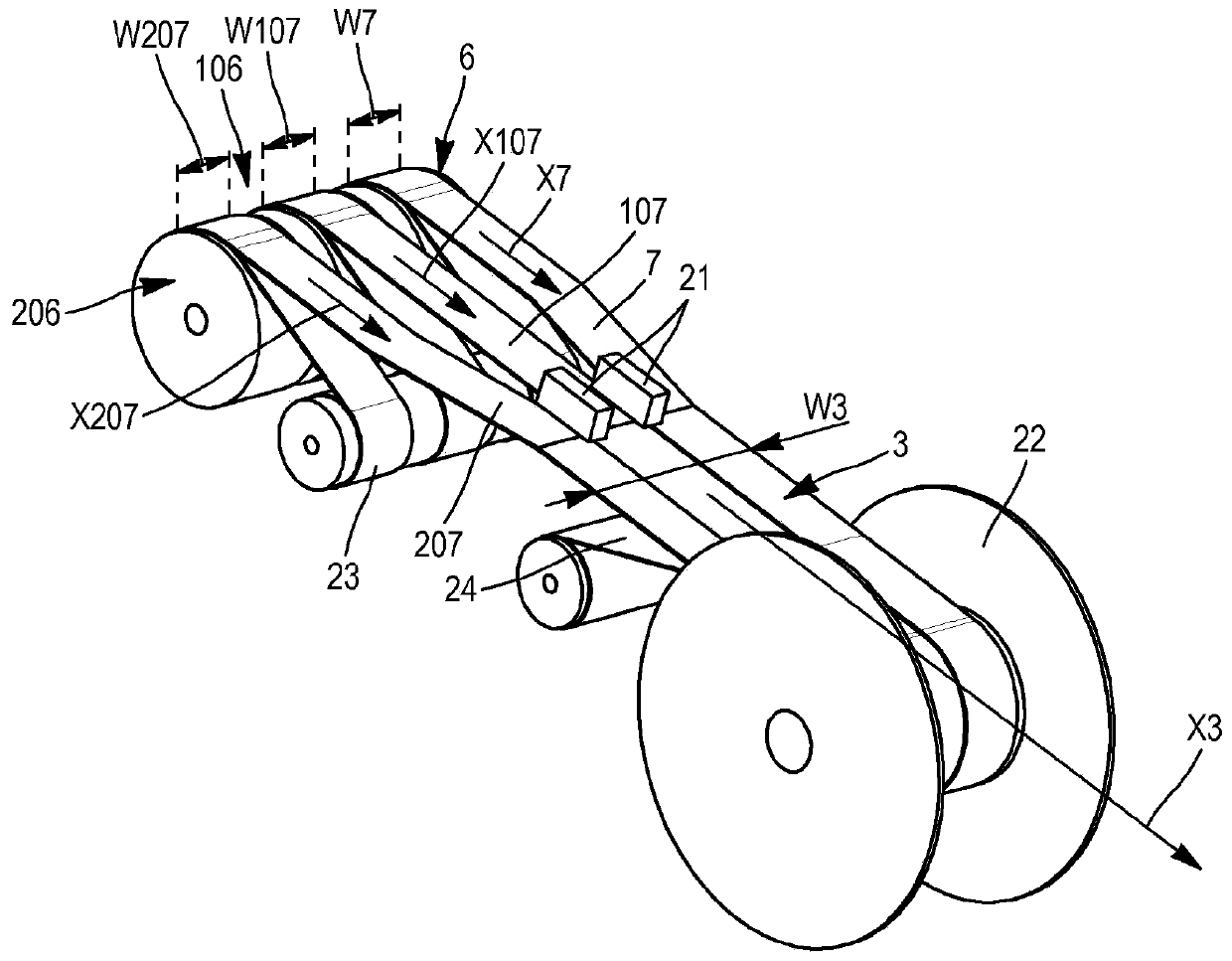

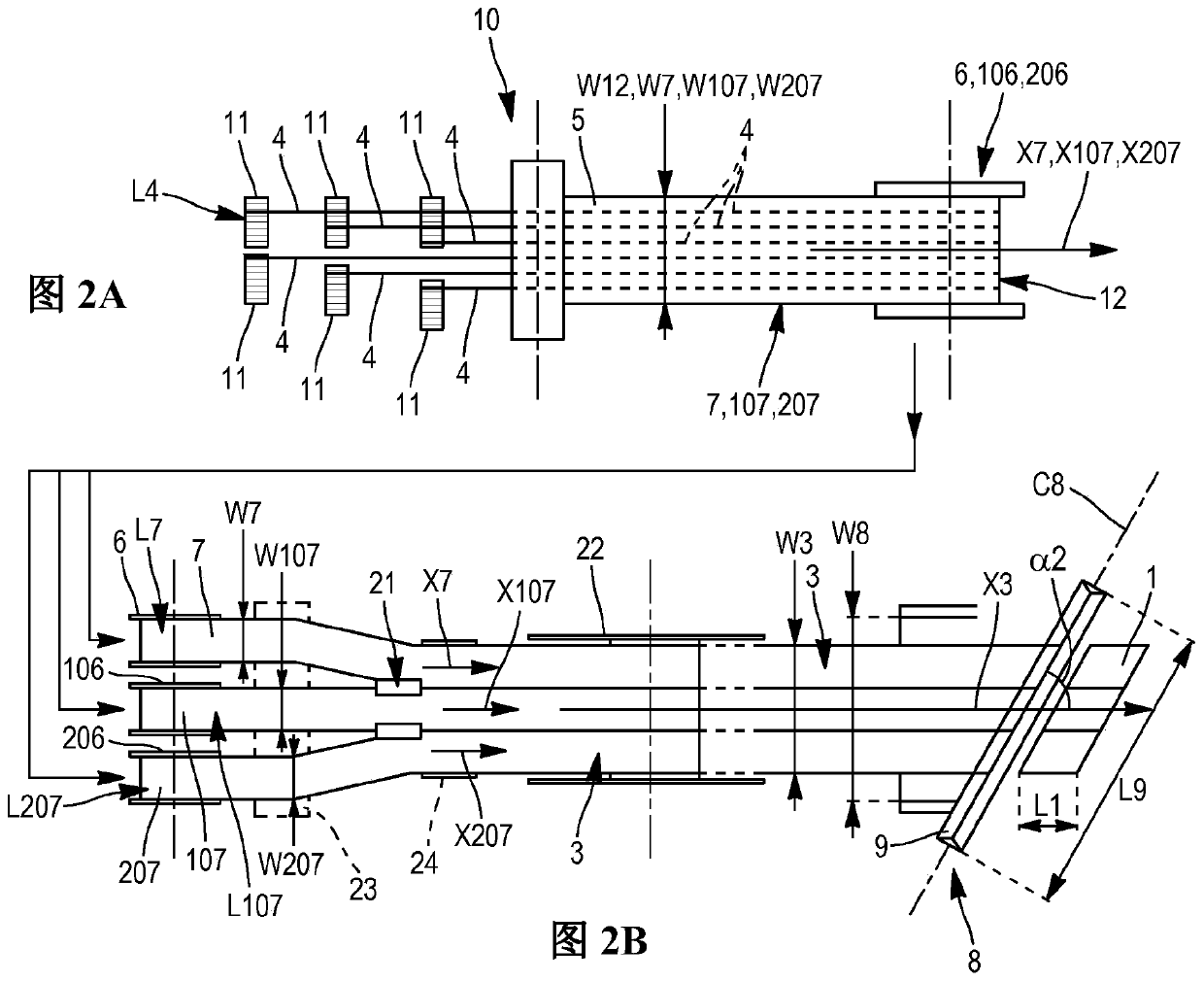

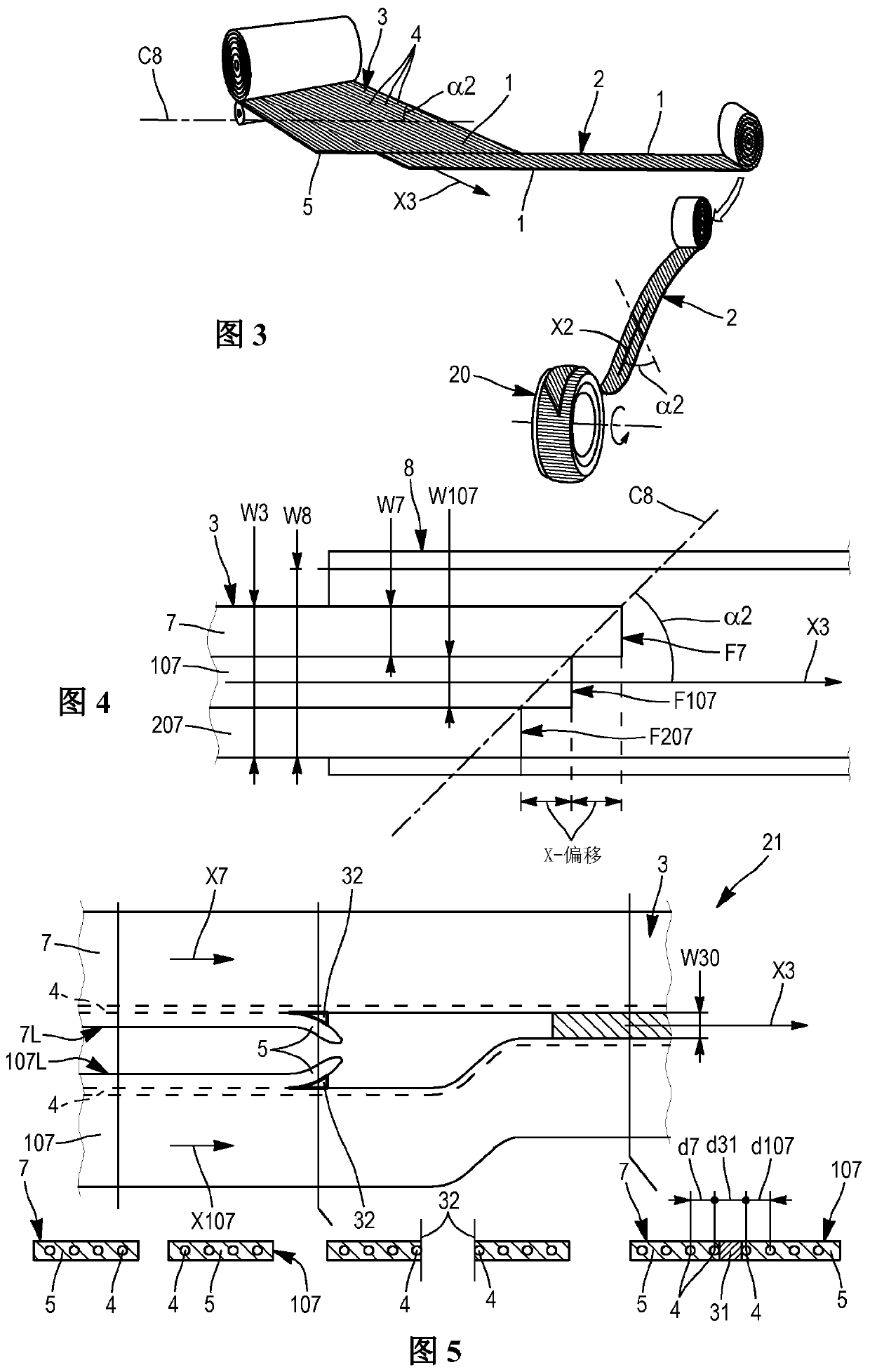

[0043] The invention relates to a method for manufacturing a web 1 intended for the formation of a reinforcing ply 2 of a tire 20 , more preferably a pneumatic tire 20 .

[0044] For simplicity and convenience of description, the terms "tyre" and "pneumatic tire" may hereinafter be equated, it being clearly understood that the present invention is applicable to the manufacture of all types of tires, including solid, non-pneumatic tires, which are used, for example, in Puncture-resistant wheels with honeycomb inner structure.

[0045] The reinforcing ply 2 may be used, for example, as a carcass ply, or as a crown ply intended to reinforce the crown of the tire 20 beneath the tread, as image 3 shown.

[0046] in a manner known per se, such as Figure 2B and image 3 As shown, and as will be described in detail below, the web 1 corresponds to a portion of a straight cord ply 3 from which it is intercepted by a cutting operation carried out in a cutting direction C8, said The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com