Rotary percussion drill with a hard material bit

a rotary percussion drill and hard material technology, applied in the direction of drilling apparatus, tool workpiece connection, manufacturing tools, etc., can solve the problems of high internal stress, drill failure, and increase internal stress in the brazing alloy and hard material bit, so as to improve the removal of abrasively removed drillings and the effect of large receiving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

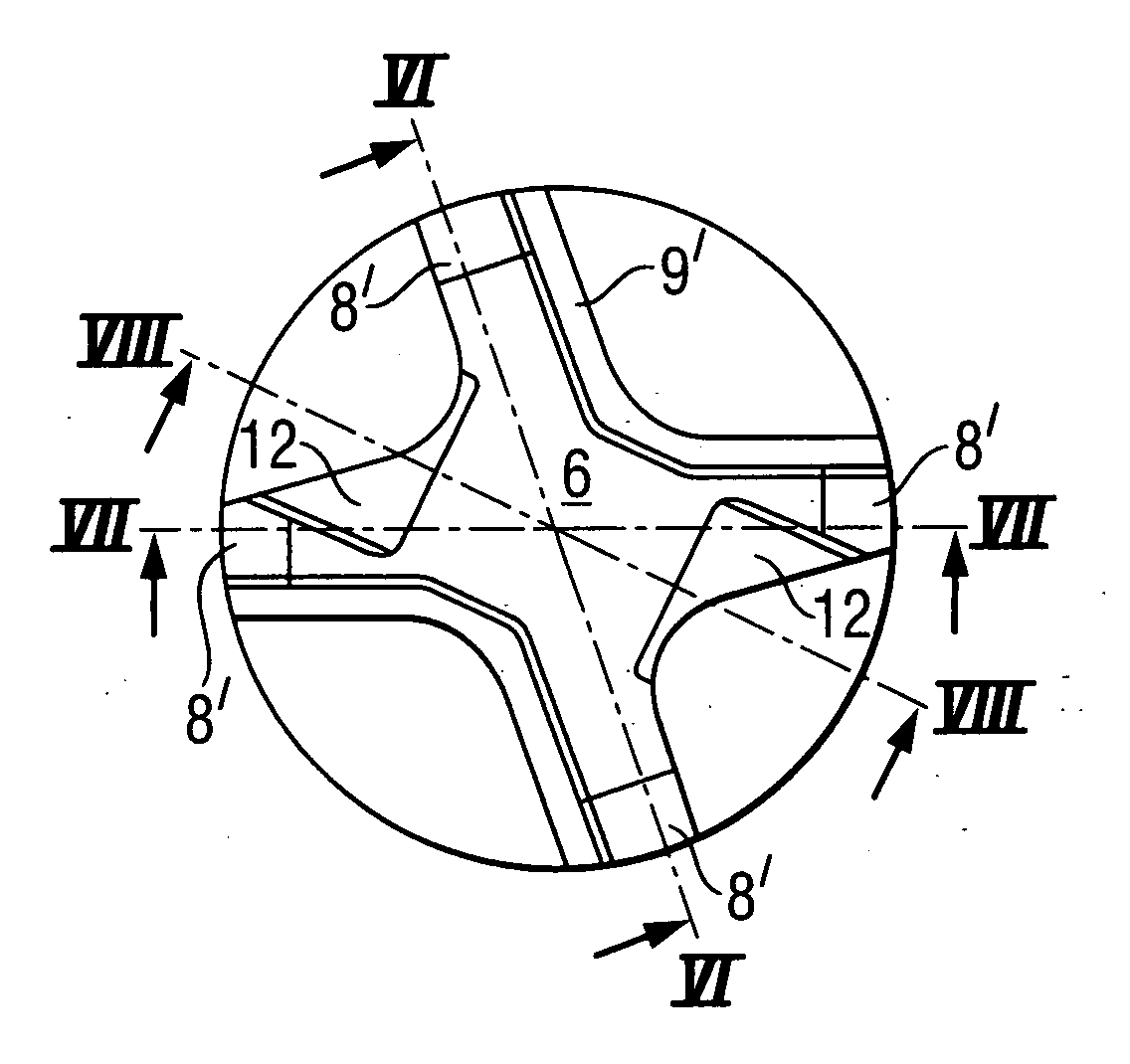

[0025]A rotary percussion drill 1 according to the present invention, which is shown in FIGS. 1-2, has a plate-shaped hard material bit 2 with a diametrically extending cutting edge 3 and a bottom surface 4 located opposite the cutting edge 3. The bottom surface 4 is secured with a brazing alloy 5 in a material-locking manner to a base surface 6 of the drill shaft end 7 in an adapted slot-shaped mortise 9. The base surface 6 is provided on diametrically opposite side of an outer radial rim with a radial chamfer 8. The axial thickness D of the layer of the brazing alloy between the base surface 6 and the bottom surface 4 of the bit 2 is overall smaller than 0.6 mm.

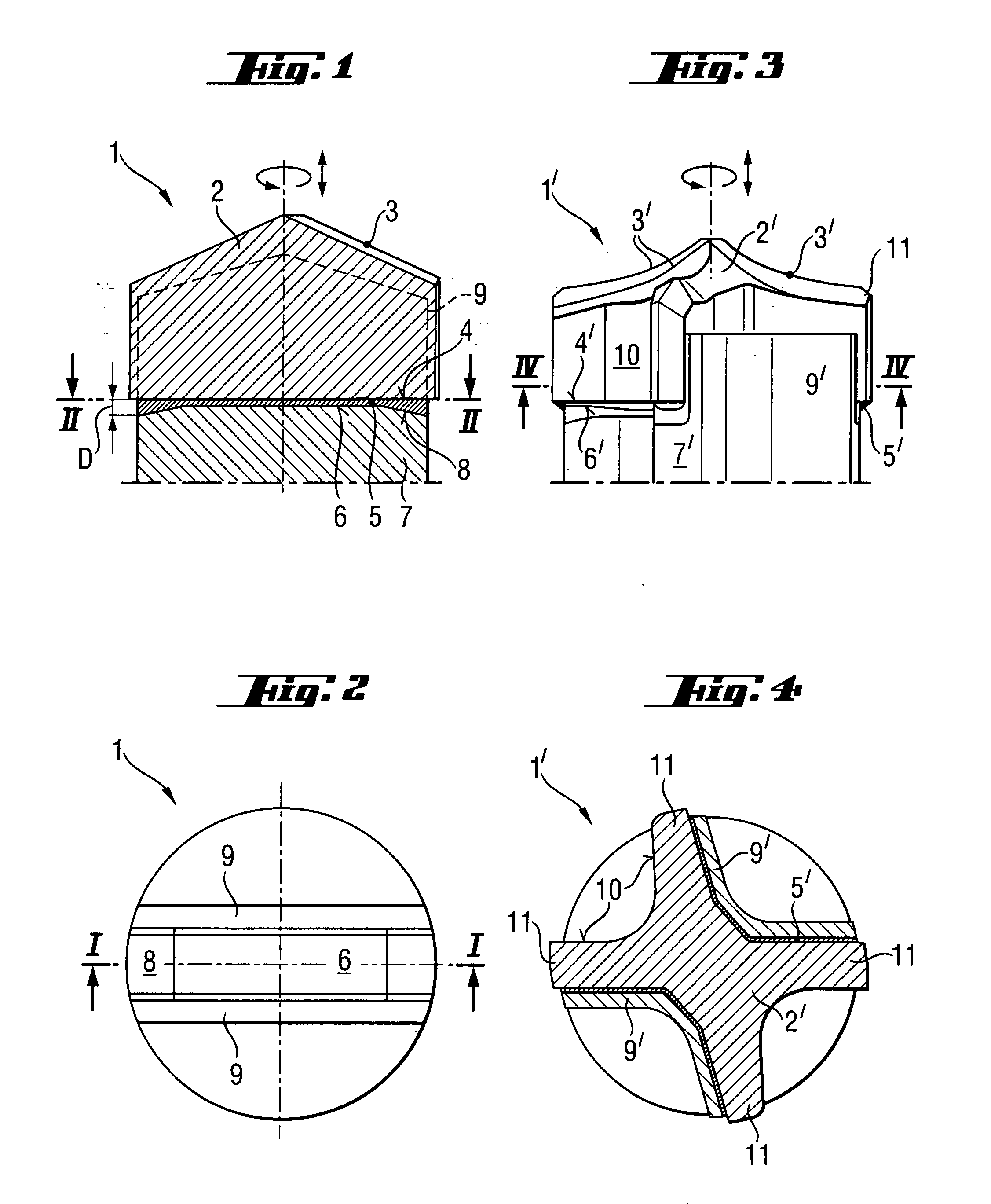

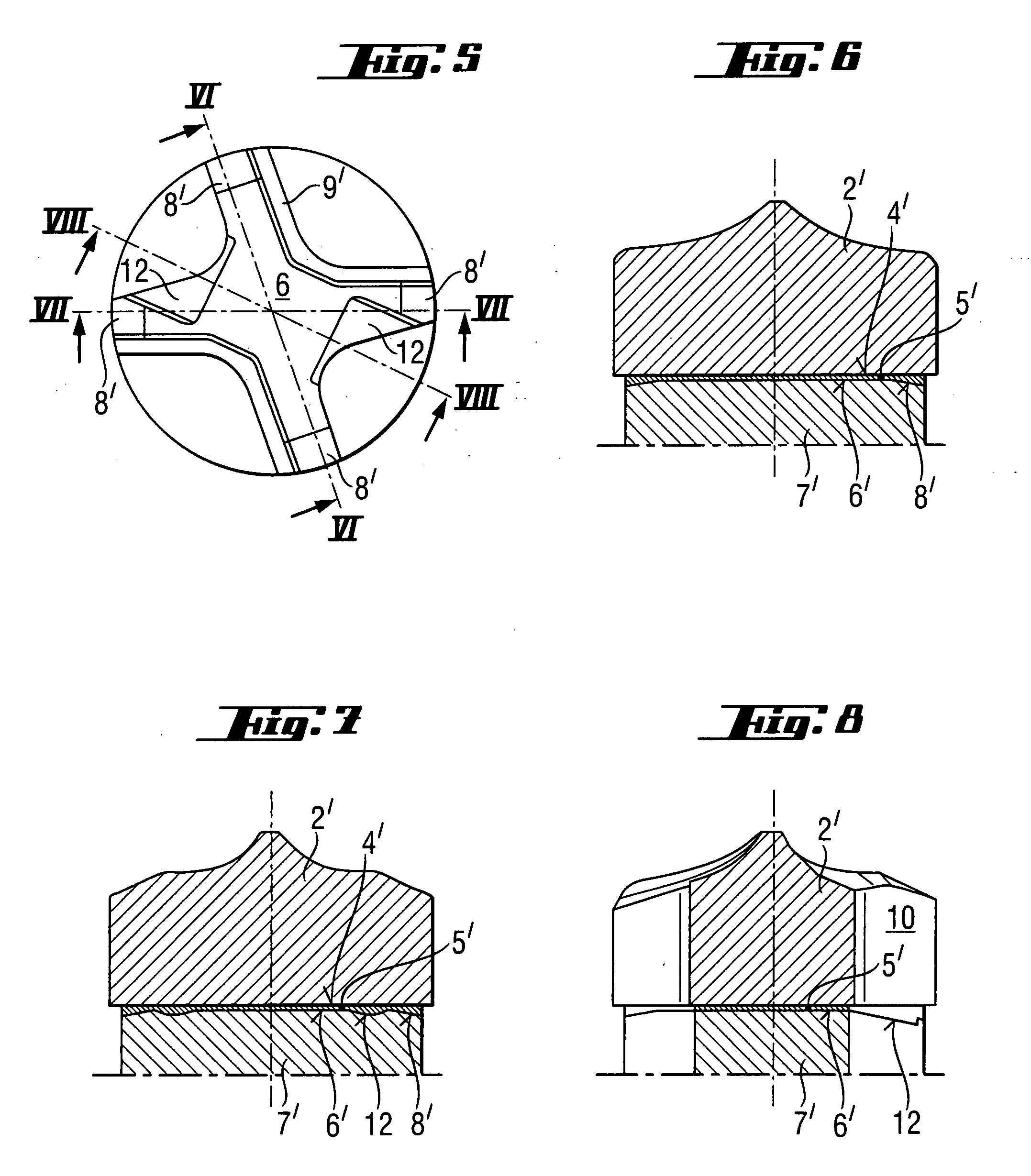

[0026]A rotary-percussion drill 1′, which is shown in FIGS. 3-8, has an X-shaped hard material bit 2′ with four radially extending blades 11 with respective cutting edges 3′. The hard material bit 2′ is secured with brazing alloy 5′ in a correspondingly adapted X-shaped mortise 9′ and is butt-brazed with its bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| axial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com