Large-size silicon wafer texturing bearing device

A bearing device, large-scale technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problem of inability to effectively reduce the pressure basket alarm and machine failure shutdown, increase the weight of the discharge device , Inability to accurately distinguish and other problems, to achieve the effect of good differentiation, high production efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

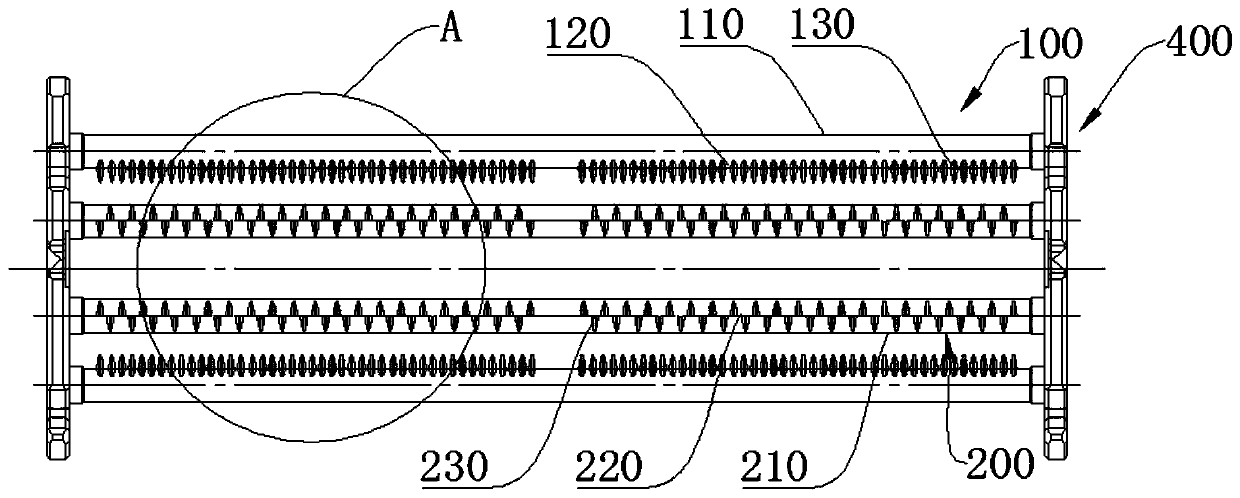

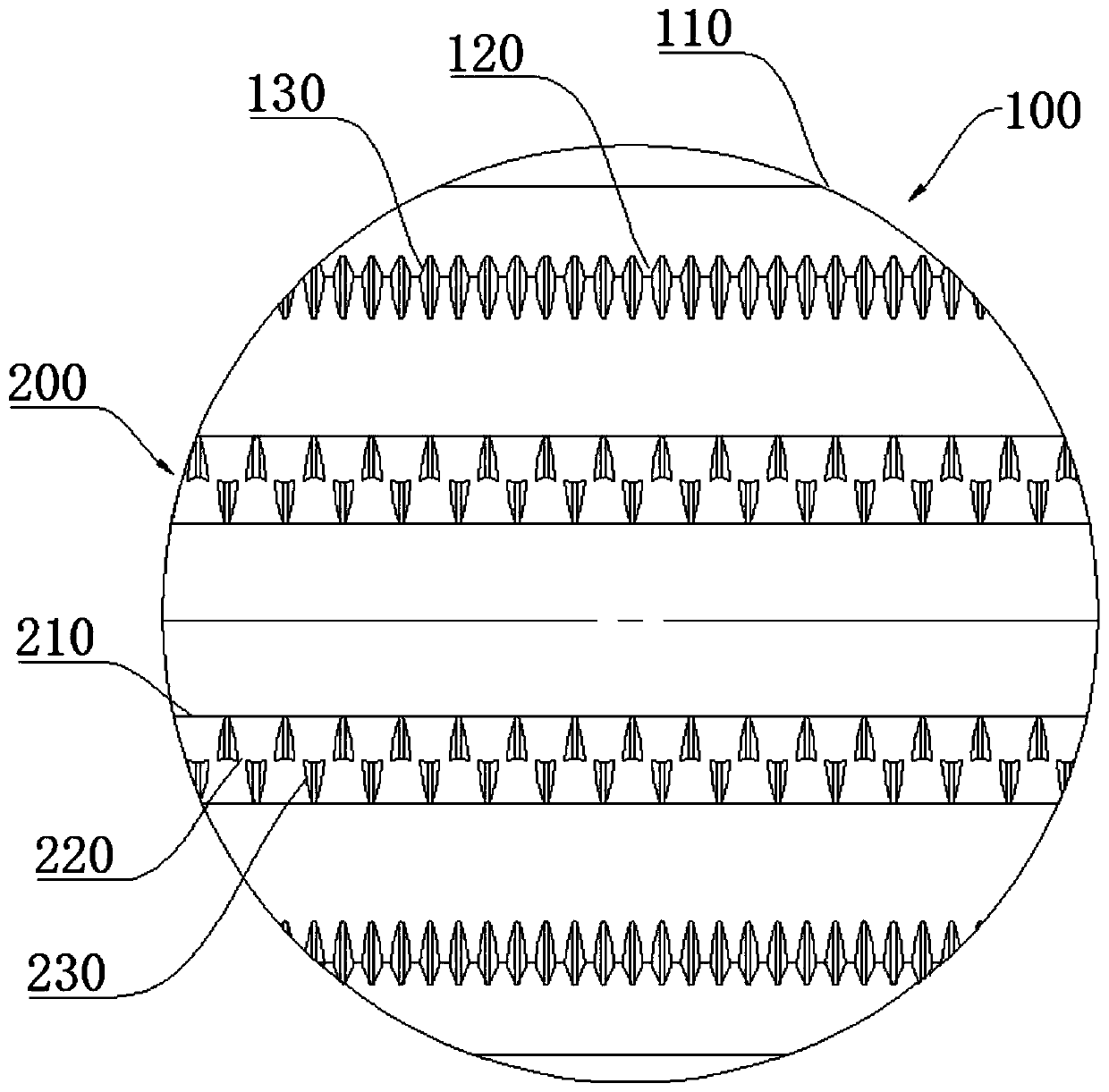

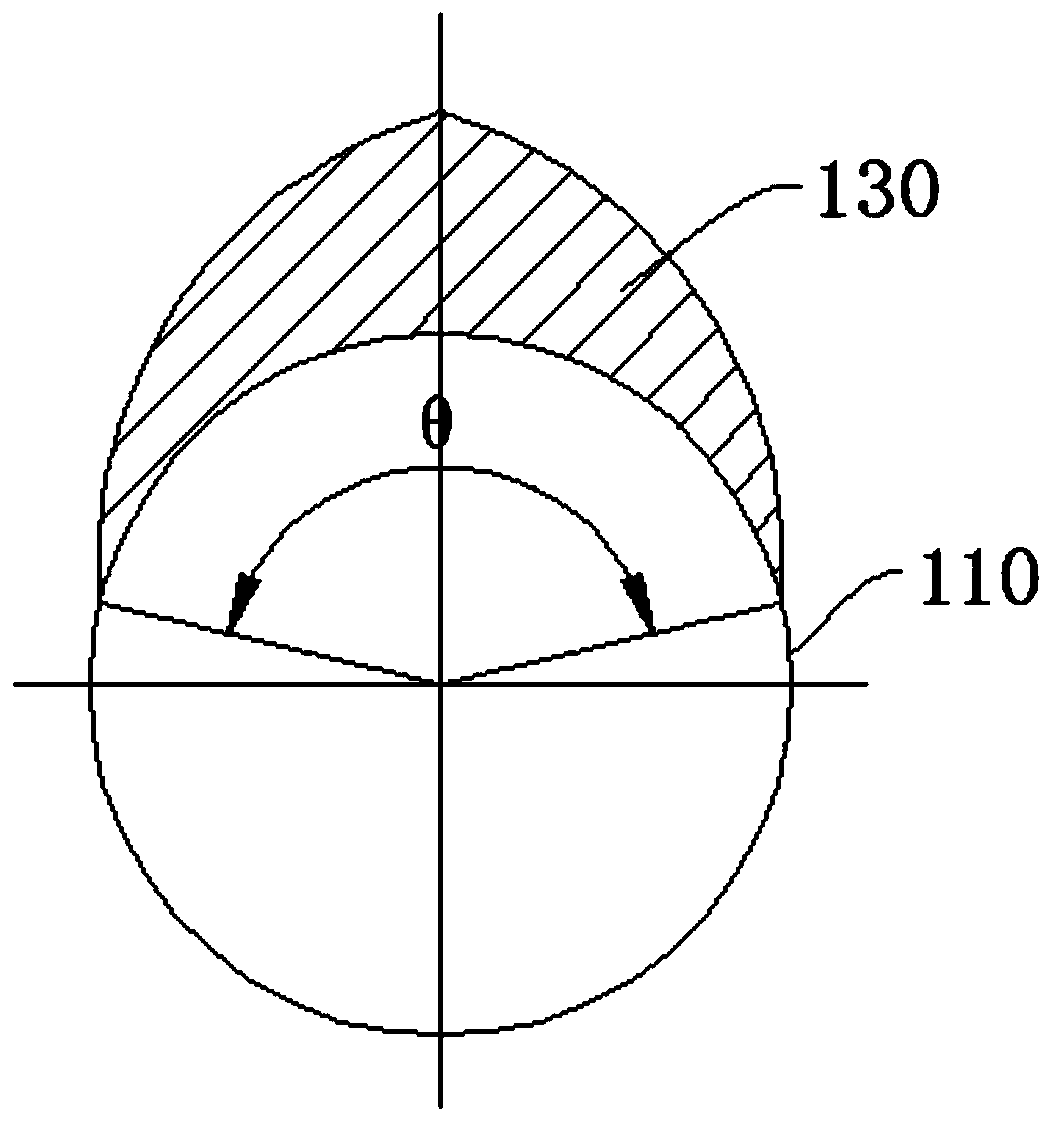

[0042] This embodiment proposes a large-size silicon wafer texturing bearing device, such as figure 1 As shown, it includes a side bar assembly 100, a bottom bar assembly 200, and an end plate assembly 300 placed at both ends of the side bar assembly 100 and the bottom bar assembly 200. The side bar assembly 100 includes several side bars 110, and the bottom bar assembly 200 includes several bottom bars. 210, the end plate assembly 400 includes a left end plate 410 and a right end plate 420, wherein, the outer wall of the side bar 110 is surrounded by a first tooth groove 120, the outer wall of the bottom bar 210 is wound with a second tooth groove 220, the first tooth groove 120 The side bar 110 and the second tooth groove 220 are arranged side by side along the axial length direction of the side bar 110 and the bottom bar 210 respectively, and both are arranged toward the silicon wafer axis direction.

[0043] Due to the large area of the silicon wafer, the vertically plac...

Embodiment 2

[0056] Such as Figure 9 As shown, compared with Embodiment 1, the biggest difference between this embodiment and Embodiment 1 is that the side bar assembly 100 is surrounded by the second tooth groove 220 , and the lower rod assembly 200 is surrounded by the first tooth groove 120 The carrying device set by this structure is formed by the cooperation of the second tooth groove 220 arranged horizontally on the side and the first tooth groove 120 arranged vertically upward on the bottom to form a slot for placing silicon chips, which can also ensure the vertical placement The silicon wafer is clamped stably, which can prevent the silicon wafer from shaking, and at the same time prevent the adjacent silicon wafers from sticking together, so as to not only ensure the uniformity of the texturing of the silicon wafer, but also further reduce the fragmentation rate of the silicon wafer; the smooth design of the first tooth The groove 120 and the second tooth groove 220 allow the tex...

Embodiment 3

[0058] Such as Figure 10 As shown, compared with Embodiment 1, the biggest difference between this embodiment and Embodiment 1 is that the side bar assembly 100 and the lower bar assembly 200 are all wound with first tooth grooves 120. This structure makes the silicon wafer and The contact area of the first tooth groove 120 increases, which in turn can make the placement of the silicon wafer more stable. The stability of the placement of the silicon wafer can further improve the yield of the silicon wafer, and at the same time reduce the probability of the bonding of the silicon wafer, thereby improving the stability of the silicon wafer. Texture-making effect ensures the quality of velvet-making.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com