Preparation method of sample for detecting austenite grain size of steel by oxidation method

A technology of austenite grain and oxidation method, which is applied in the preparation of test samples, etc., can solve the problems of increasing the inspection cycle, consuming manpower, material resources, and difficulty in grasping, so as to improve the first-time success rate, improve the detection accuracy, The effect of increasing the inspection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

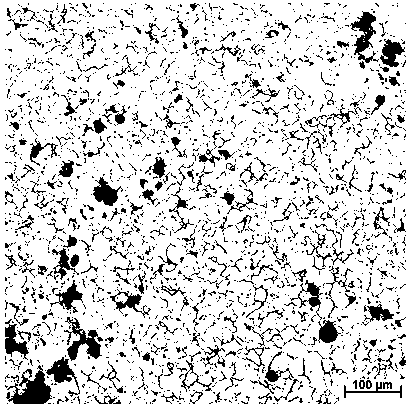

[0044] The sample preparation method for detecting the austenite grain size of steel by the oxidation method adopts the following process steps.

[0045] Process design test: GB / T6394-2017 is implemented for sample cutting, sample grinding and polishing, sample heat treatment, sample removal of iron oxide, sample polishing, sample erosion, and austenite grain size rating. The hard method is internationally recognized as the most accurate method for detecting austenite grain size. In order to verify the accuracy of the austenite grain size sample prepared by this method, direct quenching was used for each case. Hard method for comparison.

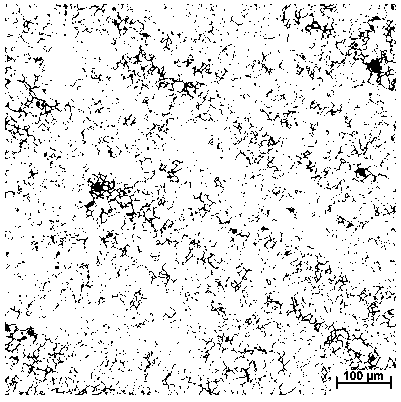

Embodiment 1

[0046] Embodiment 1: the preparation method of this oxidation method inspection steel austenite grain size sample is specifically as follows:

[0047] (1) Samples are taken from steel with a steel grade of 20, and the carbon content in the steel is ≤0.35wt%;

[0048] (2) Polish the test surface of the sample with a 3 μm abrasive;

[0049] (3) Place the polished sample in a furnace with the test side up for heat treatment, heat at 890±10°C, keep it warm for 1 hour, and then quench it in cold water;

[0050] (4) Put the test surface of the heat-treated sample in step (3) facing up, add hydrochloric acid solution dropwise to the test surface, and after bubbles appear on the surface of the sample, rinse with water and dry;

[0051] (5) Use a 3 μm particle size polishing agent to polish the test surface of the sample;

[0052] (6) After using 15% hydrochloric acid alcohol solution for erosion, the alcohol solution was rinsed and dried for inspection.

[0053] (7) The austenite g...

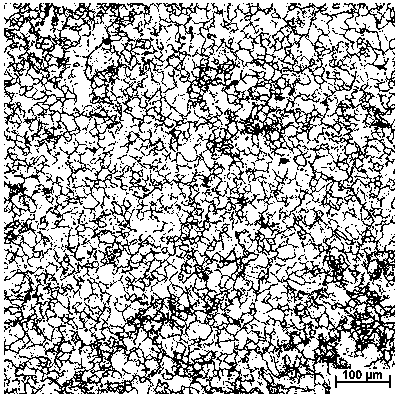

Embodiment 2

[0063] Embodiment 2: the preparation method of this oxidation method detection steel austenite grain size sample is specifically as follows:

[0064] (1) Sampling is taken from steel with a steel grade of 38MnVS6, and the carbon content in the steel is >0.35wt%;

[0065] (2) Polish the test surface of the sample with a 3 μm abrasive;

[0066] (3) Place the polished sample in a furnace with the testing side up for heat treatment, heat at 860±10°C, keep it for 1 hour, and then quench it in salt water;

[0067] (4) Put the test surface of the heat-treated sample in step (3) facing up, add hydrochloric acid solution dropwise to the test surface, and after bubbles appear on the surface of the sample, rinse with water and dry;

[0068] (5) Use a 3 μm particle size polishing agent to polish the test surface of the sample;

[0069] (6) After using 15% hydrochloric acid alcohol solution for erosion, the alcohol solution was rinsed and dried for inspection.

[0070] (7) The austenite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com