Ludwieg tube wind tunnel and high Mach number expansion method thereof

A wind tunnel and nozzle technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., to achieve the effect of improving the quality of the flow field and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

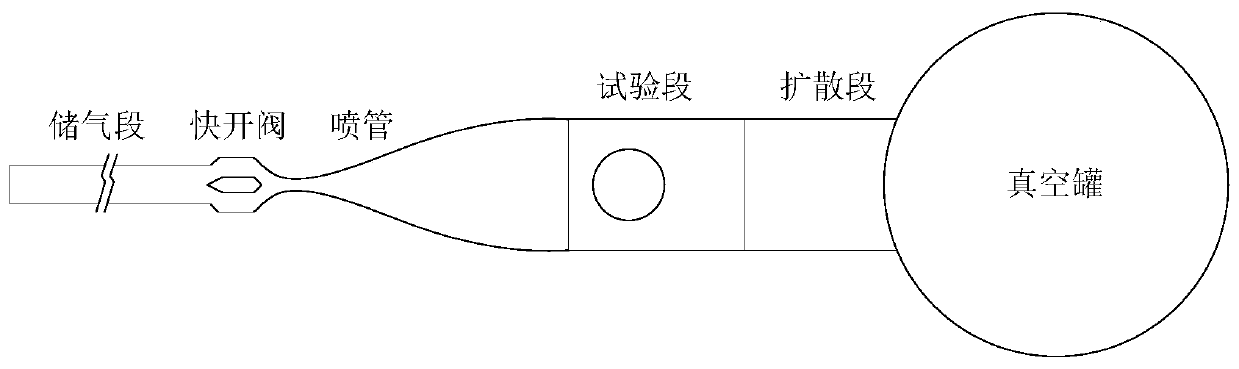

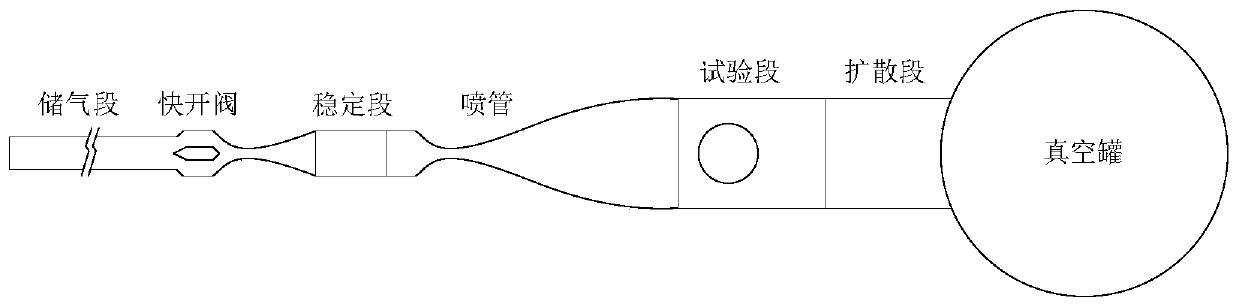

[0032] Embodiment: Ludwig tube wind tunnel variable Mach number method. In this embodiment, a Ludwig tube wind tunnel with a base Mach number of 5 and an outlet diameter of 600 mm is selected for high Mach number expansion design.

[0033] Specific steps are as follows:

[0034] 1. Design stable section

[0035] The internal profile before the throat of the stable section is consistent with the internal profile of the Mach 5 nozzle in the wind tunnel. Make sure that the quick opening valve and the stabilizer section constriction are properly engaged. The outlet diameter selection of the stable section is guaranteed to be consistent with the diameter of the air storage section of the wind tunnel. The length of the stable section is selected as twice the diameter of the outlet of the nozzle, that is, 1.2 meters. The internal profile of the expansion part of the stable section is obtained through a simple profile design.

[0036] 2. Install a high Mach number nozzle

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com