Impregnated diamond and polycrystalline diamond composite drill bit

A technology of impregnated diamond and polycrystalline diamond is applied in the field of impregnated diamond and polycrystalline diamond composite drill bits, which can solve the problems of impact resistance, poor wear resistance, short service life and disadvantage of PDC drill bits, and achieve drilling The effect of good effect, avoiding damage and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

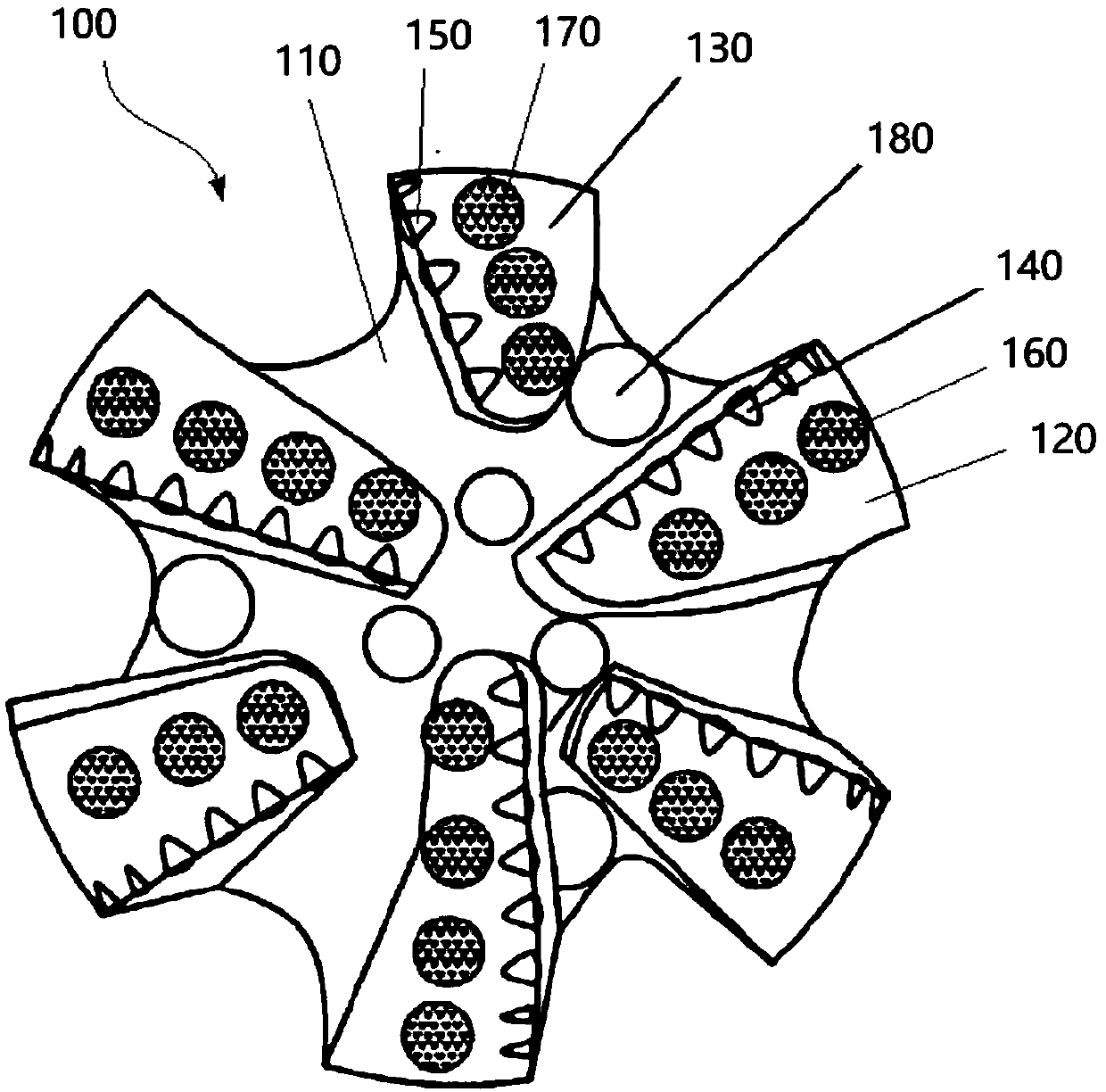

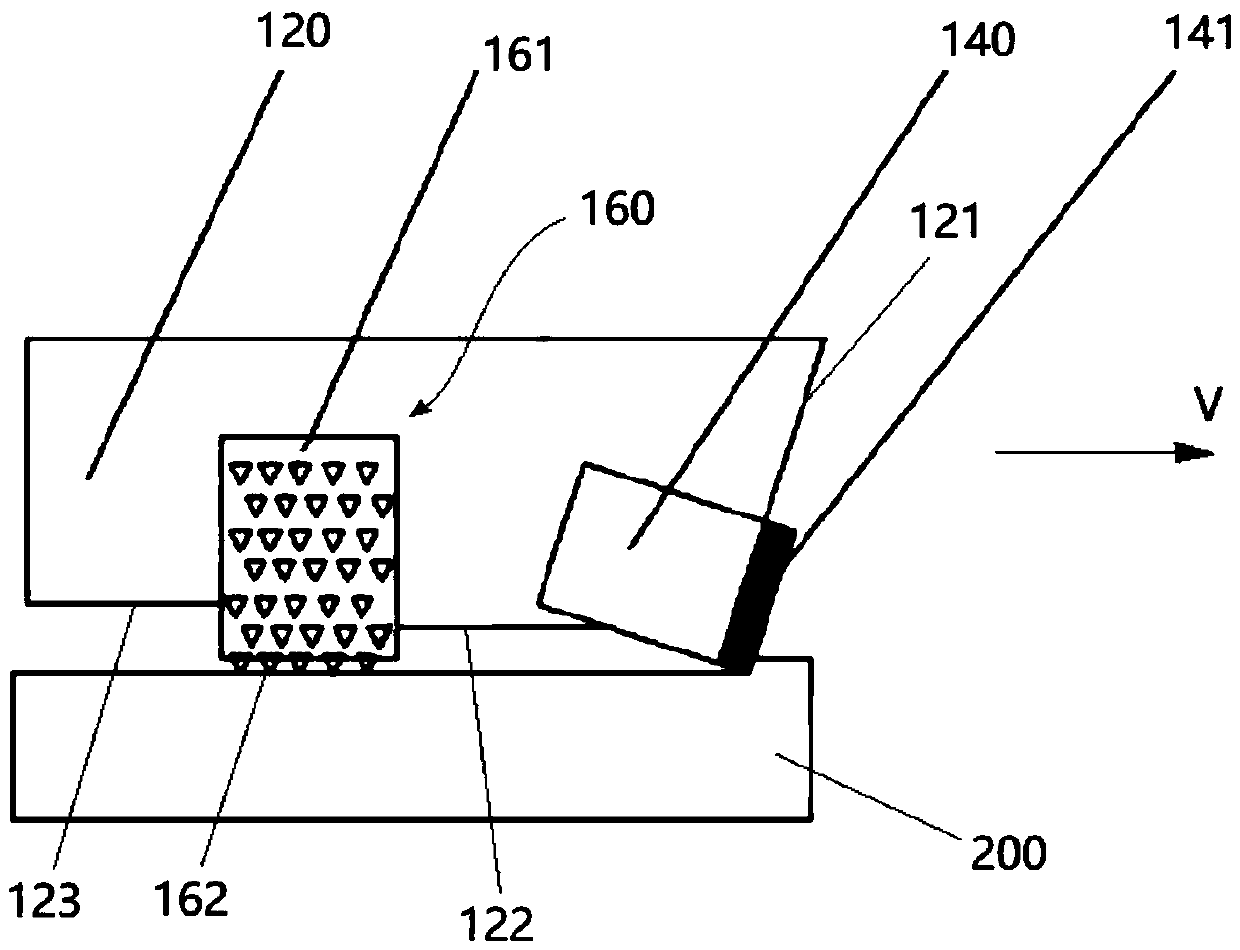

[0053] When the formation 200 is relatively hard, the drill bit 100 has 6 fins, ie, 3 first fins and 3 second fins. The diameter of the polycrystalline diamond compact is 13mm. The impregnated diamond cylinder has a diameter of 15 mm and a height of 20 mm. The axis of the cylinder is parallel to the axis of the drill bit 100 . The diameter of the diamond particles in the impregnated diamond cylinder is 2.5-3 mm. An 80% concentration of diamond particles was used. The substrate is made of 30% tungsten carbide powder with a particle size of 80 microns, 30% tungsten carbide powder with a particle size of 325 microns, 25% copper powder, 10% nickel powder and 5% manganese powder. Six water hole channels are arranged at the lower end of the rotating main body 110, which are respectively used for installing three nozzles with a diameter of 13mm and three nozzles with a diameter of 16mm.

[0054] Compared with conventional drill bits, the impregnated diamond cylinders in the drill...

Embodiment 4

[0056] When the formation 200 is relatively abrasive but moderately hard, the drill bit 100 has five fins. The specification of the polycrystalline diamond compact is 16mm. The impregnated diamond cylinder has a diameter of 15 mm and a height of 20 mm. The axis of the cylinder is parallel to the axis of the drill bit 100 . The diameter of the diamond particles in the impregnated diamond cylinder is 2.5-3mm. An 80% concentration of diamond particles was used. The substrate is made of 30% tungsten carbide powder with a particle size of 80 microns, 30% tungsten carbide powder with a particle size of 325 microns, 25% copper powder, 10% nickel powder and 5% manganese powder. . Six water eye channels are arranged at the lower end of the rotating main body 110, which are respectively used to install six nozzles with a diameter of 13 mm to assist rock breaking by means of water jetting.

[0057] Abrasive formations have severe wear on polycrystalline diamond compacts. When the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com