Non-prestress self-resetting energy dissipation supporting device provided with variable friction damper

A friction damper and energy-dissipating support technology, which is applied to building components, building types, and earthquake resistance, can solve problems such as high-order modal effects of structures, complex maintenance of energy-dissipating supports, and seismic energy dissipation, so as to reduce repair costs and difficulties. , Improve the maximum recoverable displacement, reduce the effect of residual deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

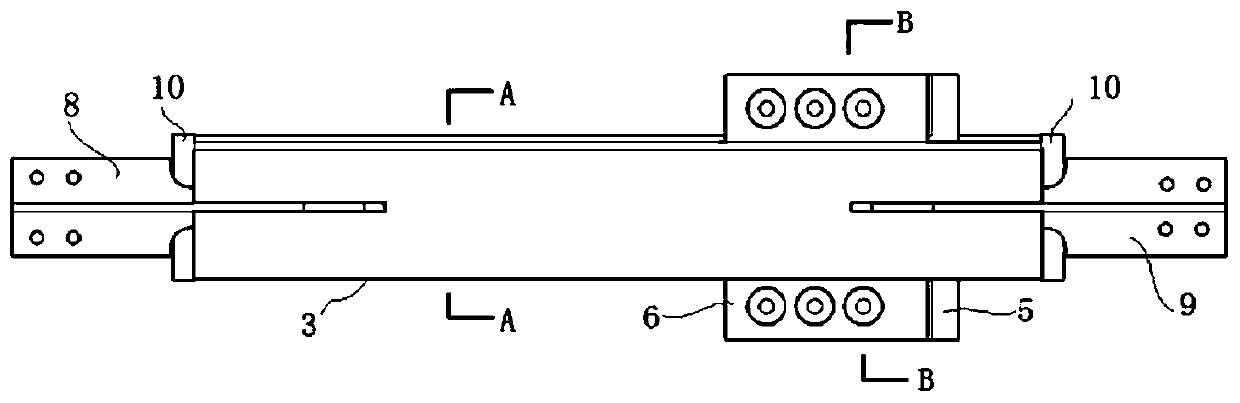

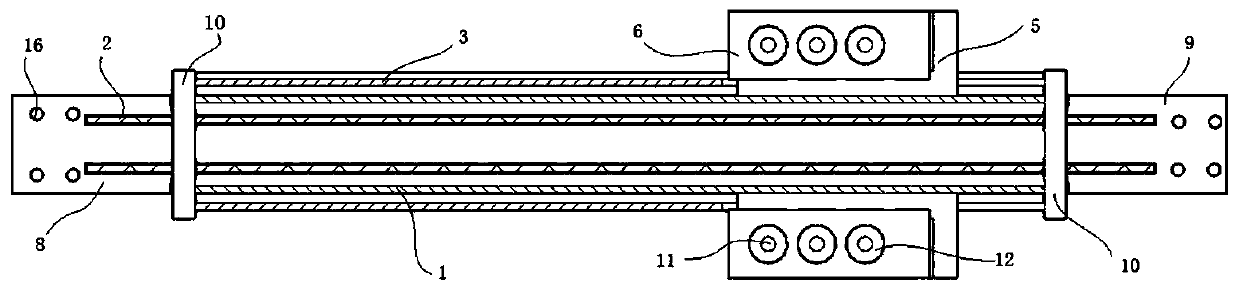

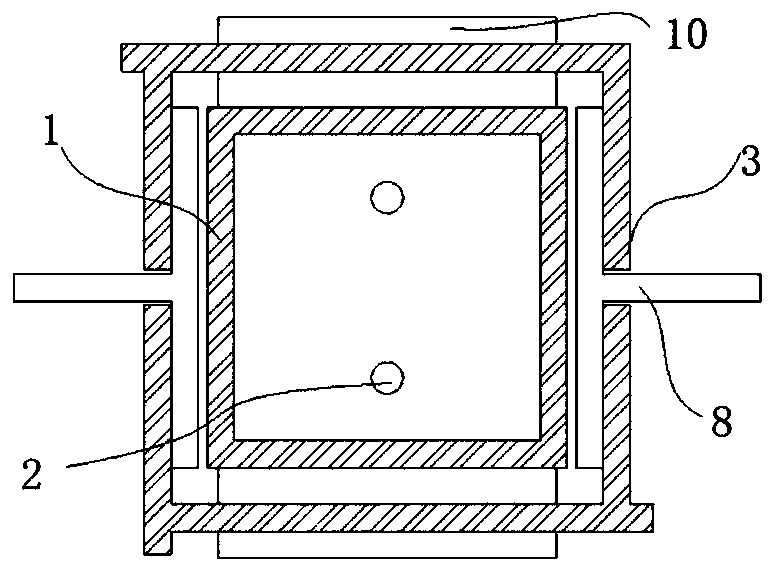

[0036] Such as Figure 1 to Figure 14As shown, the energy-dissipating support device of the present invention includes a first connecting plate 8 and a second connecting plate 9 respectively connected to building structural members, an inner sleeve 1 connected to the first connecting plate 8 and a second connecting plate The outer sleeve 3 connected with the plate 9 is sleeved on the inner sleeve 1, and the lengths of the two are equal. Both ends of the inner sleeve 1 and the outer sleeve 3 are provided with movable end plates 10, the end plates 10 are located between the first connecting plate 8 and the outer sleeve 3, between the second connecting plate 9 and the inner sleeve 1, two Several pre-tension rods 2 are arranged between the end plates 10, preferably 2-3, and the pre-tension rods 2 pass through the inner sleeve 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com