A kind of carrier pile construction technology

A construction technology and carrier pile technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems such as uneven stress of anchors in pile holes, affecting the bearing capacity of carrier piles, and not having simultaneous compression. , to achieve the effect of reducing manual labor, reducing the cost of foundation treatment, and ensuring the structural strength of the bottom end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 Disclosed in the present invention is the construction process of the pull-out steel bar, the carrier pile, the hollow column hammer for construction and the carrier pile.

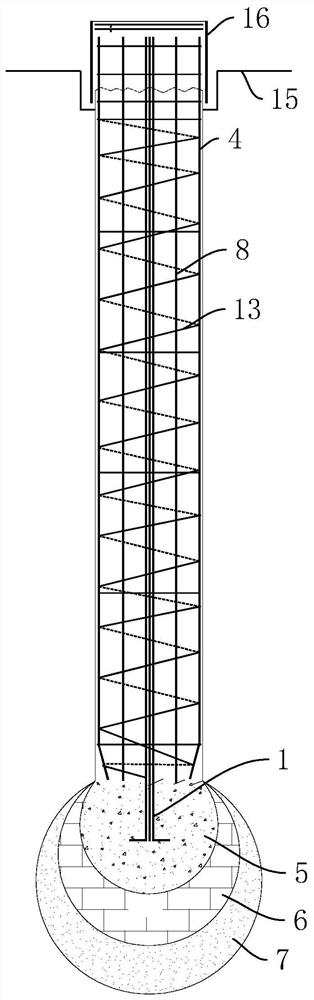

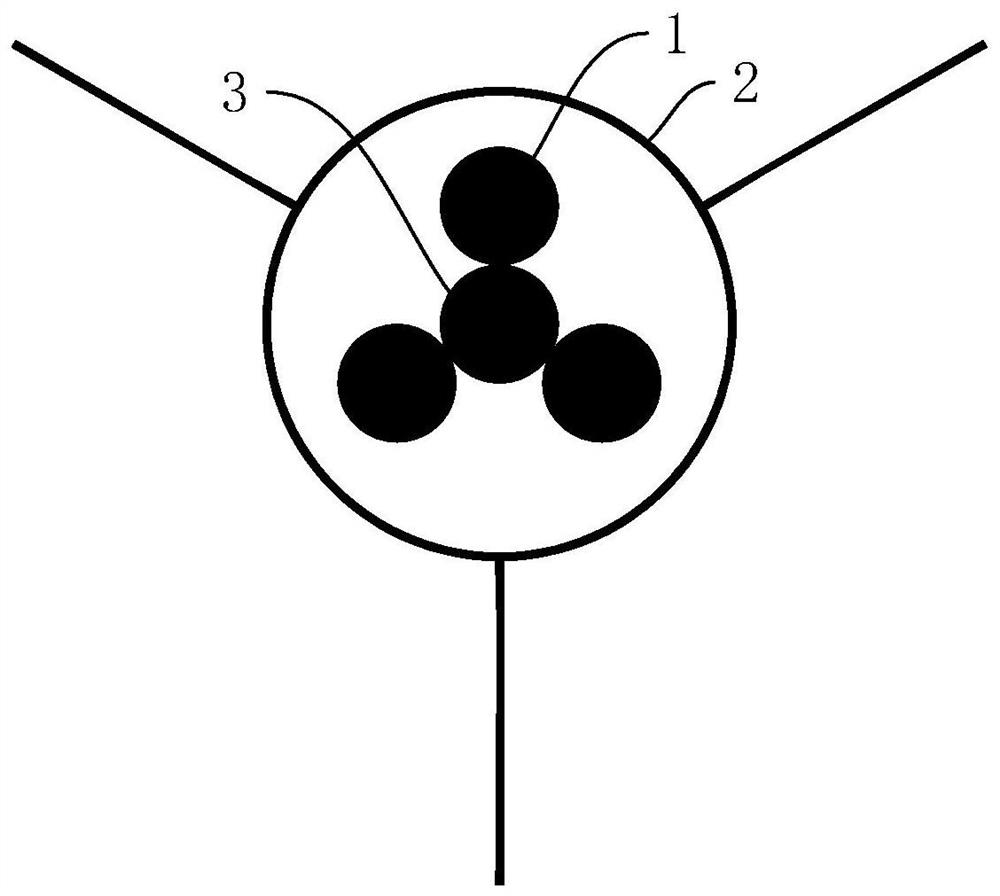

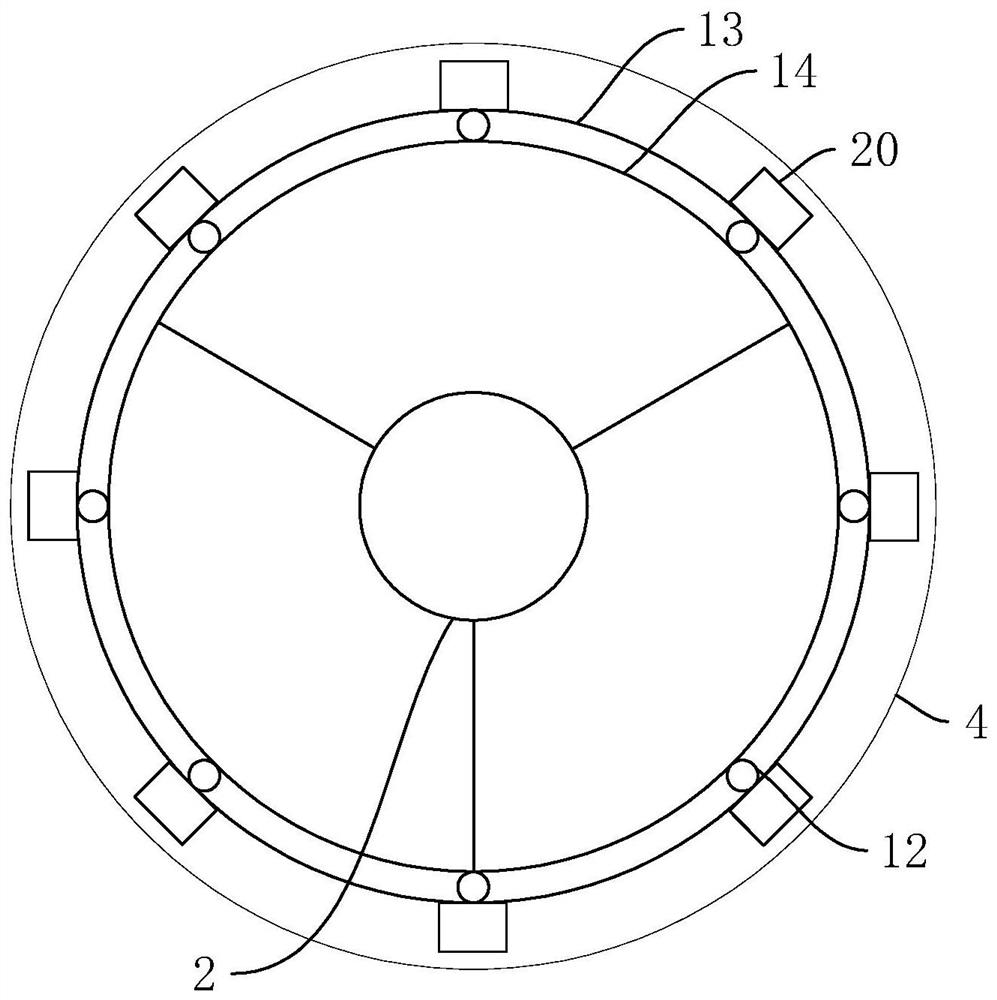

[0055] Pull-out steel bars, see figure 1 , located inside the carrier pile and hammered into the pile hole, the tensile reinforcement includes a plurality of tensile longitudinal reinforcement 1 fixed in a bundle, and the tensile longitudinal reinforcement 1 is made of HRB400 rebar, refer to figure 2 , the tensile longitudinal bars 1 in the present embodiment are preferably three, and the three tensile longitudinal bars 1 are arranged at an angle of 120 degrees to each other, and the three tensile longitudinal bars 1 are connected by double-sided welding of the middle welding reinforcement bar 3 , the bottom ends of the tensile longitudinal reinforcement 1 are all set in a curved shape of 85-95 degrees. refer to figure 1 In this embodiment, it is preferred to bend at 90 degrees. The ...

Embodiment 2

[0081] The difference between embodiment two and embodiment one is:

[0082] refer to Figure 9 , the concrete pile body 4 includes a prefabricated pile 9 and a cement mortar grouting body 10, the prefabricated pile 9 is prefabricated by concrete and a plurality of steel cages 8, the prefabricated pile 9 is a round tubular pile or a square tubular pile, and the prefabricated pile 9 A pipe pile hole 11 for accommodating the tensile longitudinal reinforcement 1 is formed in the center, and cement mortar is poured around the tensile longitudinal reinforcement 1 in the pipe pile hole 11 to form a cement mortar grouting body 10, and the pile end of the concrete pile body 4 is provided with a bearing The platform 15 and the raft 16 , and the ends of the multiple tensile longitudinal reinforcements 1 in the concrete pile body 4 away from the bending section all extend upward into the cap 15 .

Embodiment 3

[0083] The difference between embodiment three and embodiment two is:

[0084] refer to Figure 10 , the ends of the plurality of tensile longitudinal reinforcements 1 in the concrete pile body 4 away from the bending section do not enter into the cap 15 and the raft 16 .

[0085] The carrier pile construction process of embodiment two and embodiment three is the same, specifically: steps S1-S6 and step S9 of the above two embodiments are the same as steps S1-S6 and step S9 of embodiment one, refer to Figure 11 , the difference from Example 1 is:

[0086] S7: Install prefabricated piles 9, prefabricate multiple steel cages 8 and concrete to form prefabricated piles 9, hoist the prefabricated piles 9 through the hoist and put them into the steel sleeve, and penetrate the tensile longitudinal bars 1 into the prefabricated piles 9 In the pipe pile hole 11, measure the elevation of the prefabricated pile 9 and adjust the prefabricated pile 9 within the allowable error range, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com