Staged reaction system of IC anaerobic reactor

An anaerobic reactor and reaction system technology, which is applied in the field of IC anaerobic reactor staged reaction system, can solve the problems of affecting the treatment effect, increasing the hydraulic load, and affecting the full contact between organic matter and microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Here, it should be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same structure and function, and redundant descriptions on components that are substantially the same are omitted in order to make the description more concise.

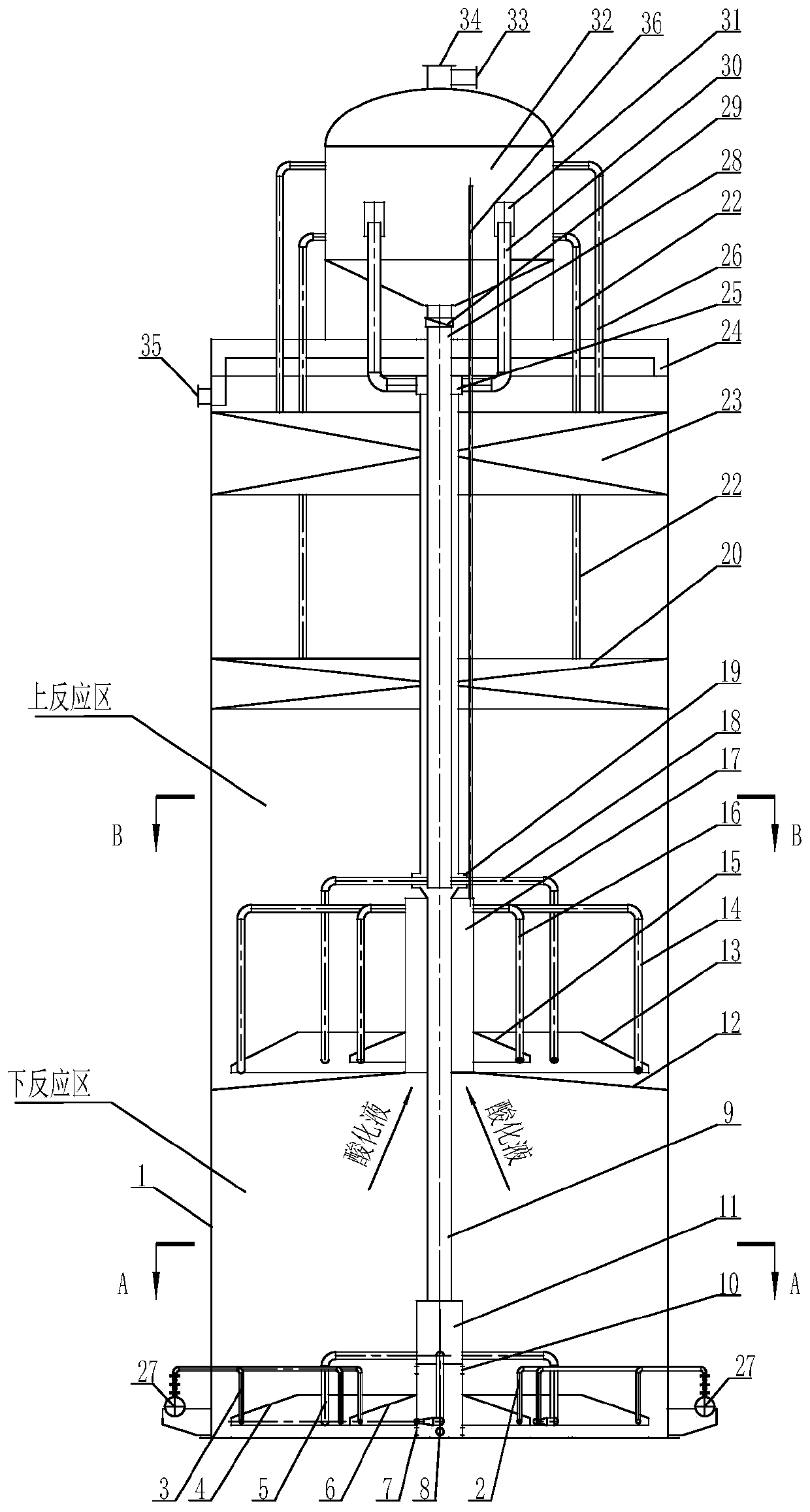

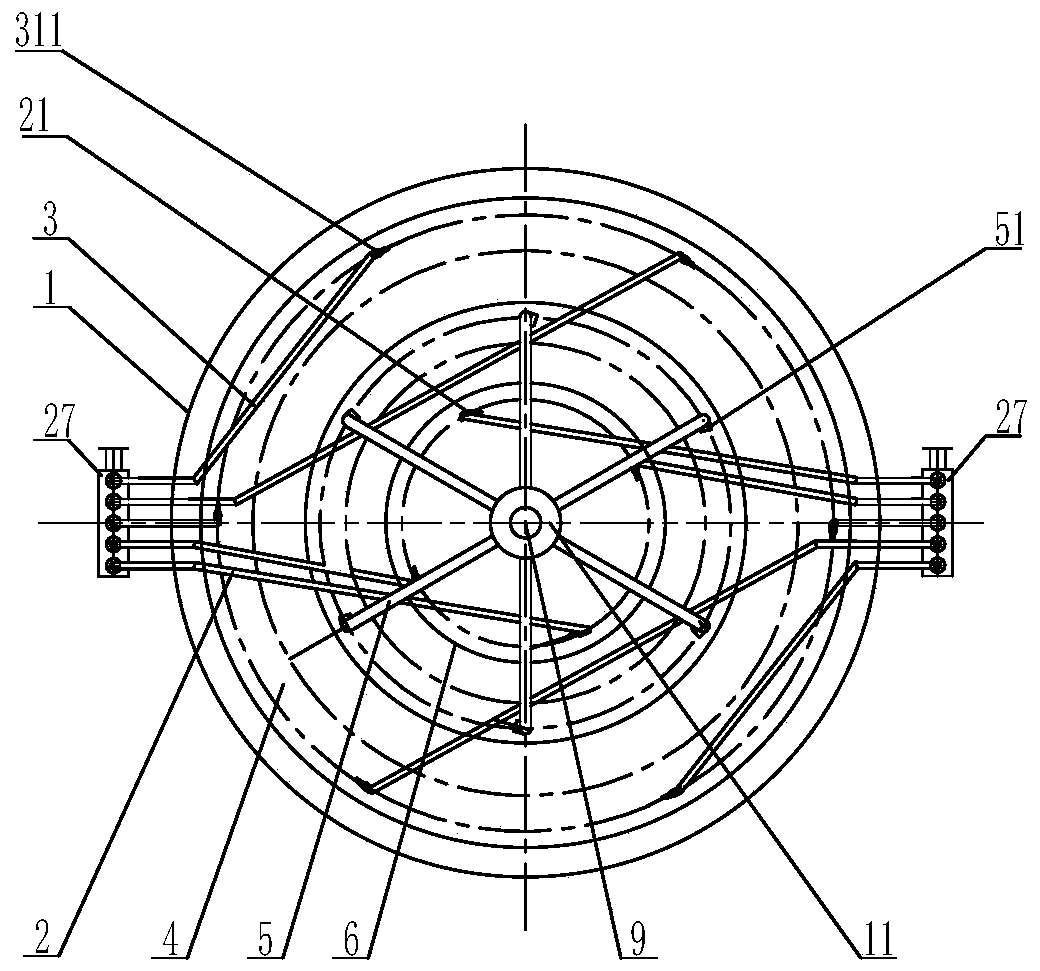

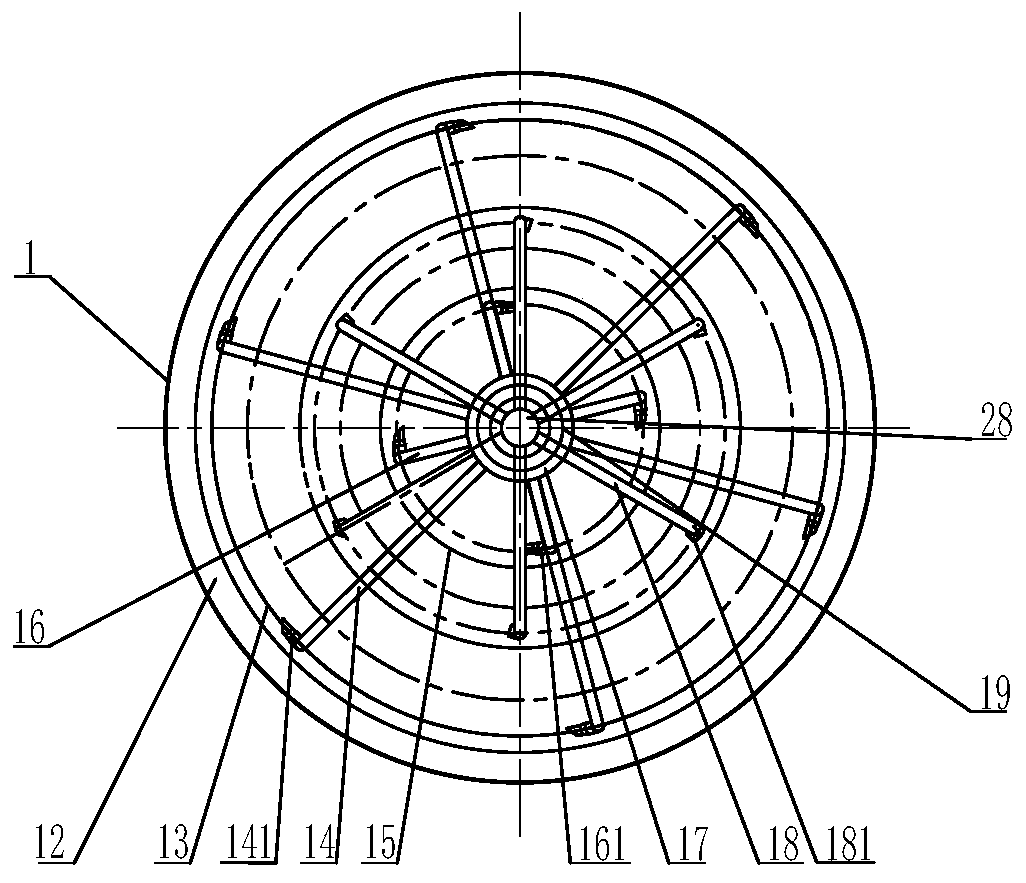

[0022] Such as figure 1 As shown, the IC anaerobic reactor staged reaction system includes a tank body 1 and a gas-liquid separator 32, the gas-liquid separator 32 is arranged on the upper side of the tank body 1, and a gas collection device is arranged on the upper part of the tank body 1, so that The gas collection device is connected to the gas-liquid separator 32 through a riser pipe, and the inside of the tank is divided into an upper reaction zone and a lower reaction zone by a partition plate 12. The gas collection device is located above the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com