A fully automatic one-to-two mask machine conveying mechanism

A conveying mechanism, fully automatic technology, applied in transportation and packaging, thin material handling, object supply, etc., can solve the problem of inability to quickly switch between children's masks and adult masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

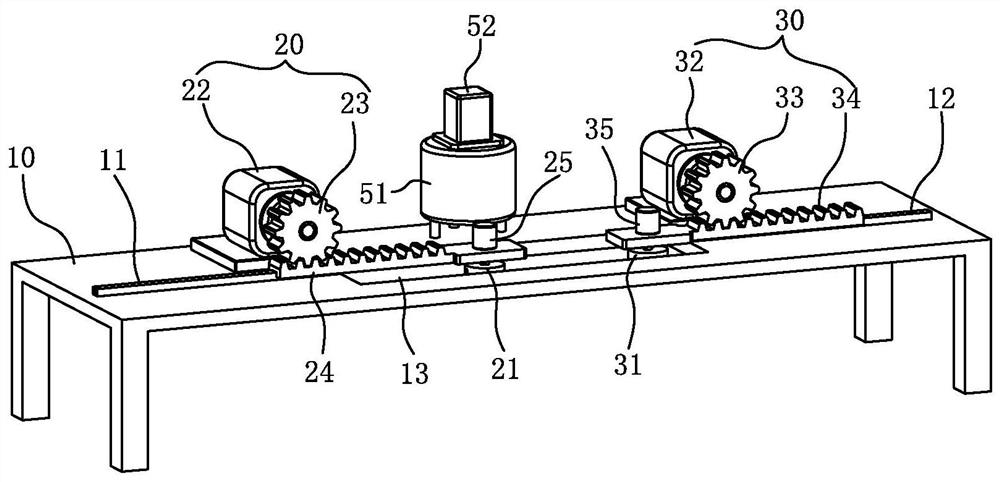

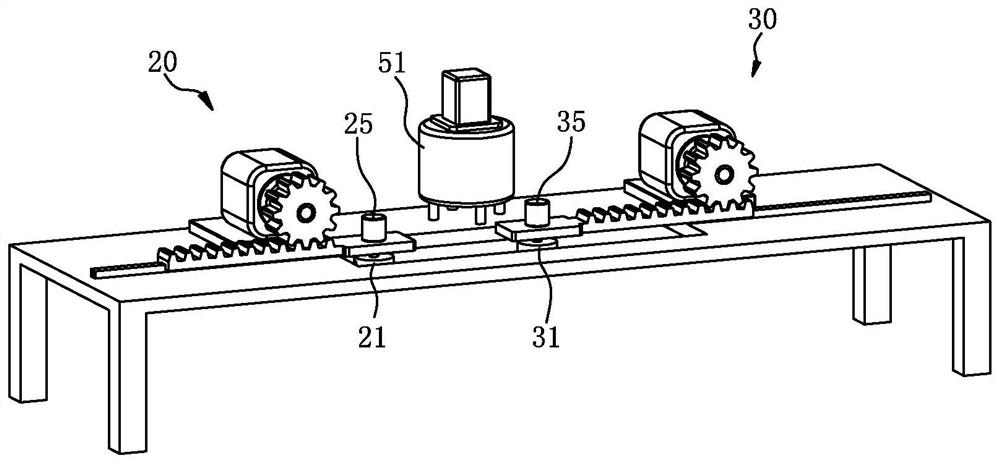

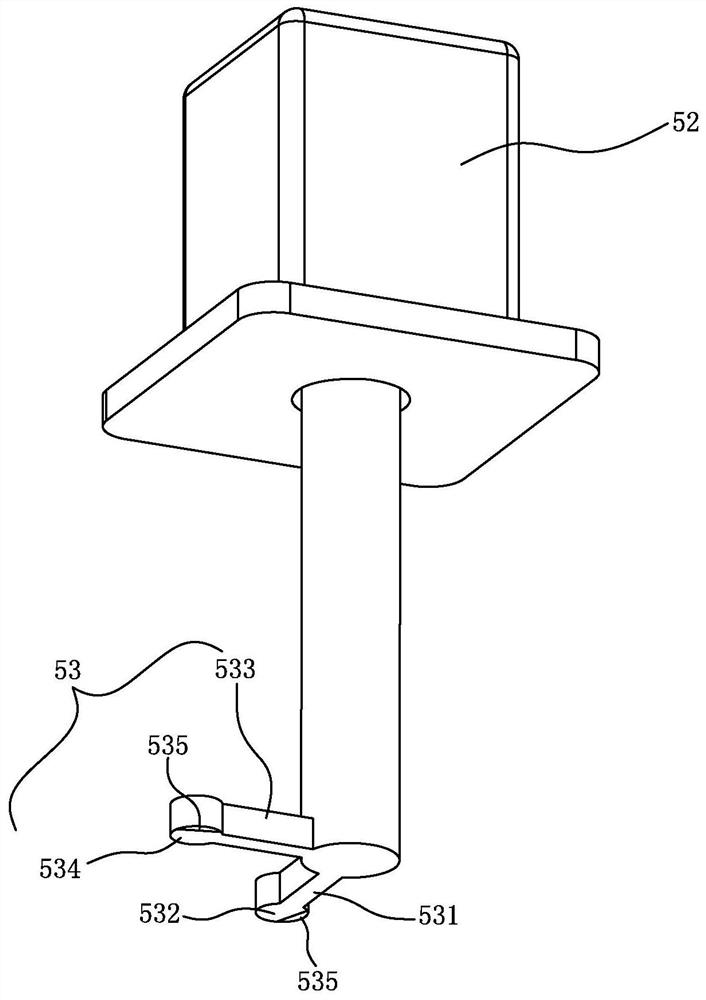

[0050] Such as Figure 1 to Figure 10As shown, the present invention relates to a fully automatic one-drag-two mask machine delivery mechanism, including: a bracket 10 and a first delivery mechanism 20 , a second delivery mechanism 30 and a switching mechanism 50 all arranged on the bracket 10 .

[0051] The support 10 is erected above the output line of the mask body processing equipment, and the conveying direction of the first conveying mechanism 20 and the second conveying mechanism 30 is perpendicular to the conveying direction of the mask body processing equipment output line.

[0052] The first conveying mechanism 20 and the second conveying mechanism 30 successively take the mask body from the output line of the mask body processing equipment and transport them to the input end of the first earband welding equipment and the input e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com