A fully automatic one drag two mask machine

A fully automatic, mask technology, applied in the field of mask machines, can solve the problem of low production efficiency, achieve the effect of improving production efficiency, improving the scope of application, and saving the time of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present case will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0060] like Figure 1 to Figure 5 As shown in the figure, a fully automatic one-to-two mask machine involved in the present invention includes mask body processing equipment, first earband welding equipment, second earband welding equipment and conveying mechanism, and the mask body processing equipment has an output line, The first ear band welding equipment and the second ear band welding device also have input ends, and the conveying mechanism distributes and delivers the mask body processed by the mask body processing equipment to the first ear band welding device and the second ear band in turn. Input terminal of welding equipment.

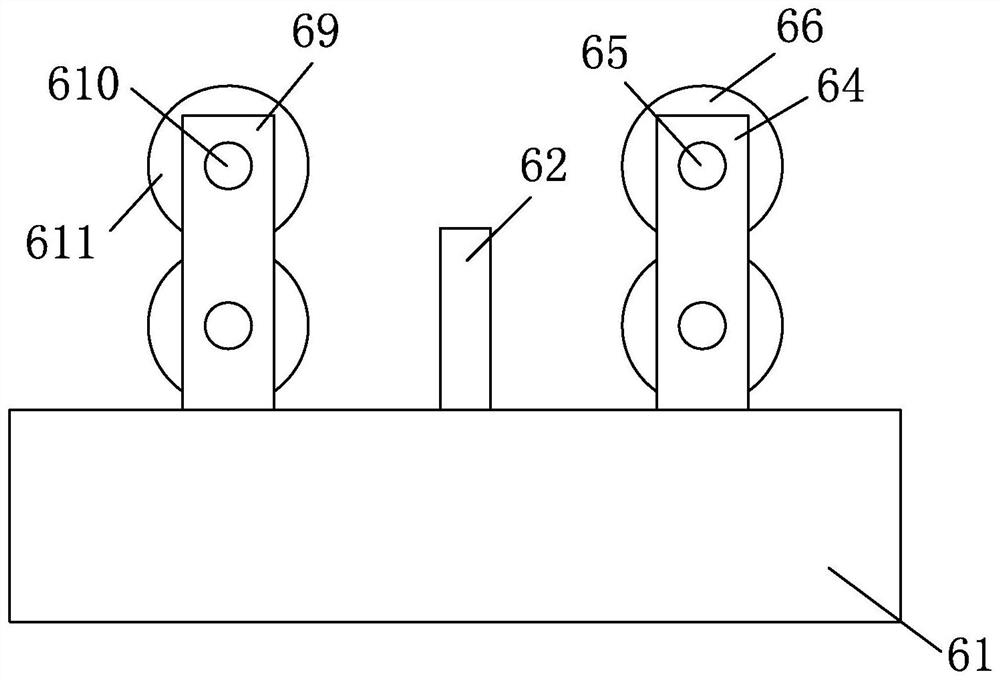

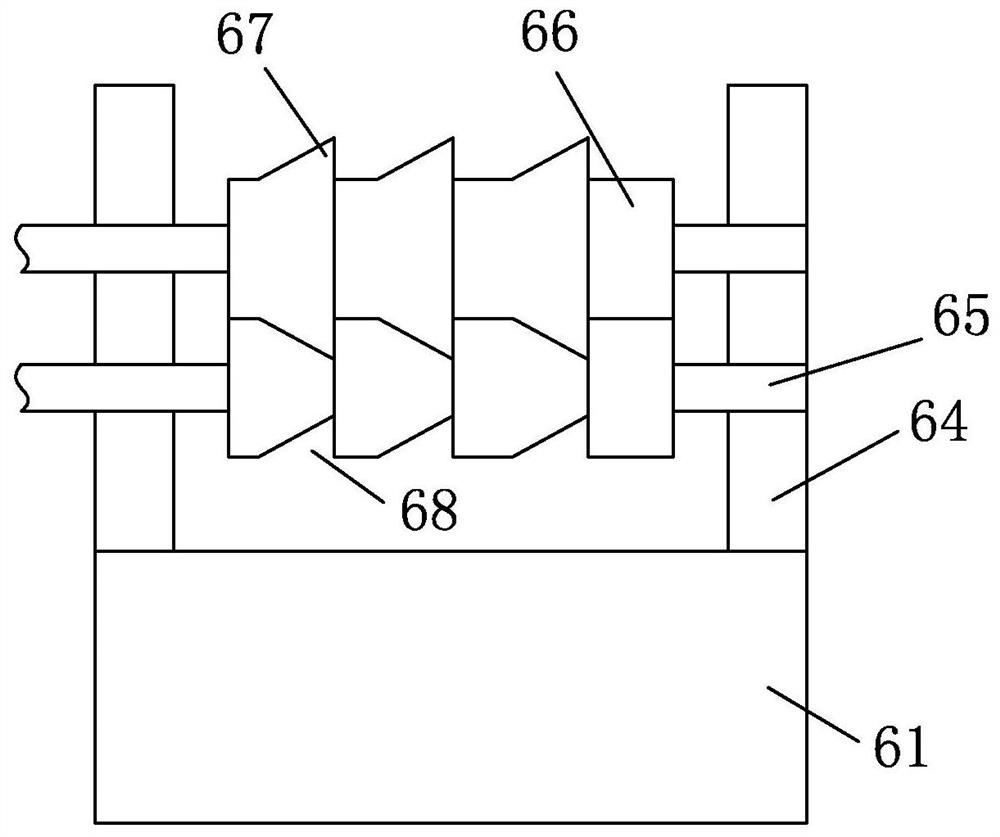

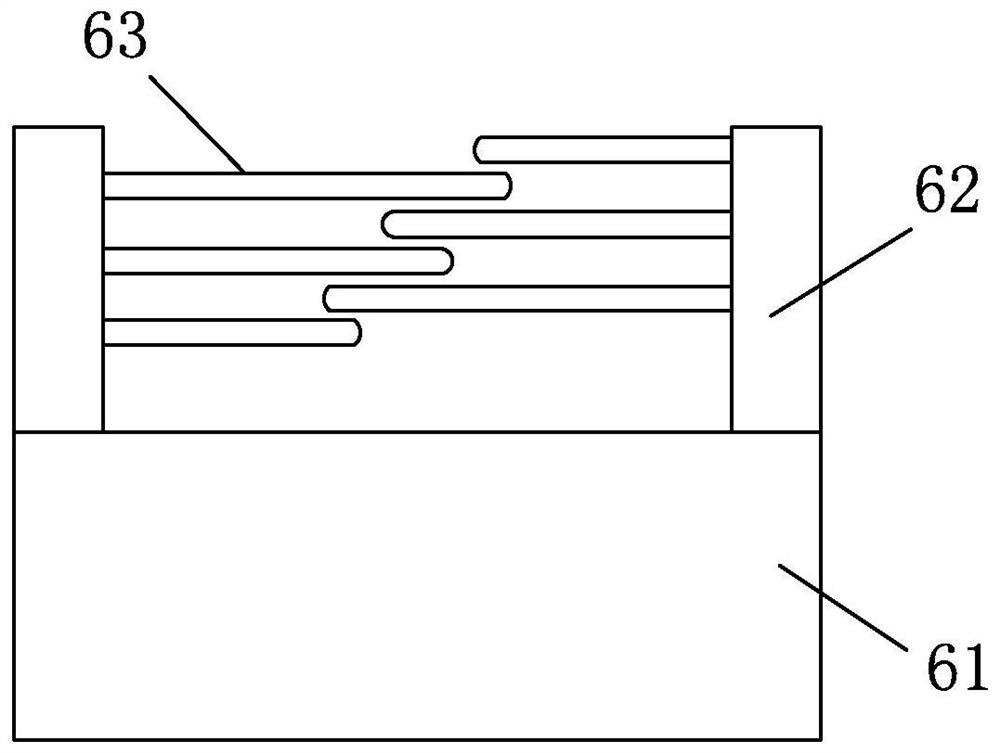

[0061] The mask body processing equipment has a folding and forming device. The folding and forming device includes a fixed base 61, a shaping roller 66, a folding plate 63 and a shaping roller 611. A pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com