A kind of suture method of composite material

A composite material and stitching needle technology, which is applied in the field of composite material stitching and pre-formed composite material processing, can solve the problems of high cost and lack of versatility of the stitching platform, and can prevent thread breakage, facilitate transfer, and reduce needle drop. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

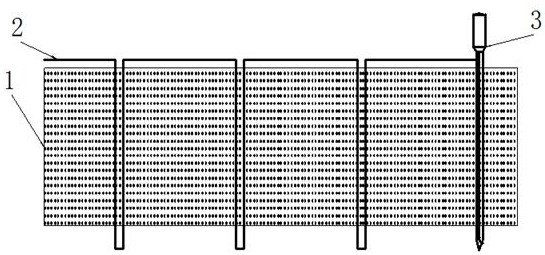

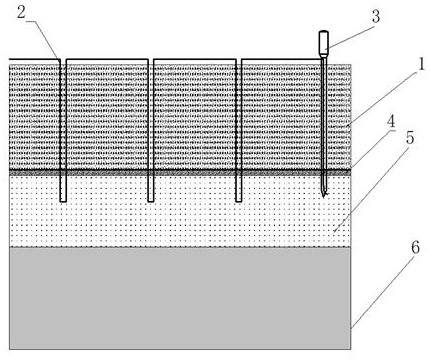

[0020] See figure 2 , a kind of sewing method of composite material of the present invention, the steps are:

[0021] S1 Fix the PMI foam pad under the composite parts that need to be stitched;

[0022] S2 Set a plastic film between the composite material part and the PMI foam pad;

[0023] S3 uses the thread hole to be set at the tip of the sewing needle and the suture passes through the composite material and then plunges into the PMI foam;

[0024] S4 Lift the sewing needle so that the suture remains in the composite part and PMI foam;

[0025] S5 Repeat steps S3 and S4 until the stitching is completed.

Embodiment 2

[0027] See figure 2 , a method for improving stitching quality, comprising composite material parts 1, sutures 2, sewing needles 3, plastic film 4, arranging PMI foam pads 5 on a table top 6, and using double-sided between the table top 6 and the PMI foam pad 5 Tape bonding; PMI foam pad 5 thickness is greater than or equal to 30mm, and area is less than or equal to the area of table top 6; PMI foam pad 2 can be replaced according to the size of the stitched parts, the number of times of use, etc.; stick the plastic film 4 around the PMI foam pad 5 with tape When sewing, the composite material part 1 is placed on the plastic film 4, and the sewing needle 3 passes through the sewing part with the suture 2, and then passes through the plastic film 4 and then plunges into the PMI foam pad 5, because the sewing needle 3. It can move up and down freely in the PMI foam, and at the same time, the suture is retained by the friction of the PMI foam, and there is no need to design a ...

Embodiment 3

[0029] The present invention is a method for improving the sewing quality. During the sewing work, the composite material part 1 is placed on the plastic film 4, and when the sewing needle 3 moves downward, after passing through the composite material part 1 with the suture 2, the sewing The needle 3 carries the suture 2 through the plastic film 4 and then plunges into the PMI foam pad 5. The friction between the needle 3 and the PMI foam makes the suture 2 stay in the PMI foam pad 5; the suture 2 is covered by the PMI foam. Pad 5 bites, and like this suture thread 2 just is difficult to leave composite material part 1 with the upward movement of suture needle 3 again, has avoided the occurrence of the needle dropping problem, has improved suturing quality. After the composite material part 1 is stitched, the adhesive tape for pasting the plastic film 4 and the PMI foam pad 5 is peeled off, and the plastic film 4 and the composite material part 1 are taken off from the PMI foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com