Tuna peptide, extraction method thereof and application of tuna peptide as antihypertensive agent

An extraction method, tuna technology, applied in the fields of application, fish protein components, medical preparations containing active ingredients, etc., can solve the problems of increased processing difficulty, accompanying fishy smell, unsatisfactory purity of tuna peptides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

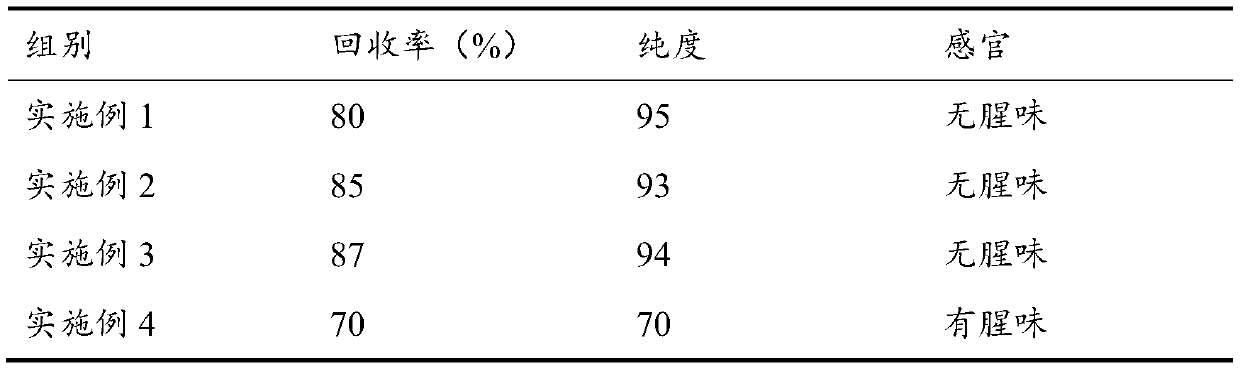

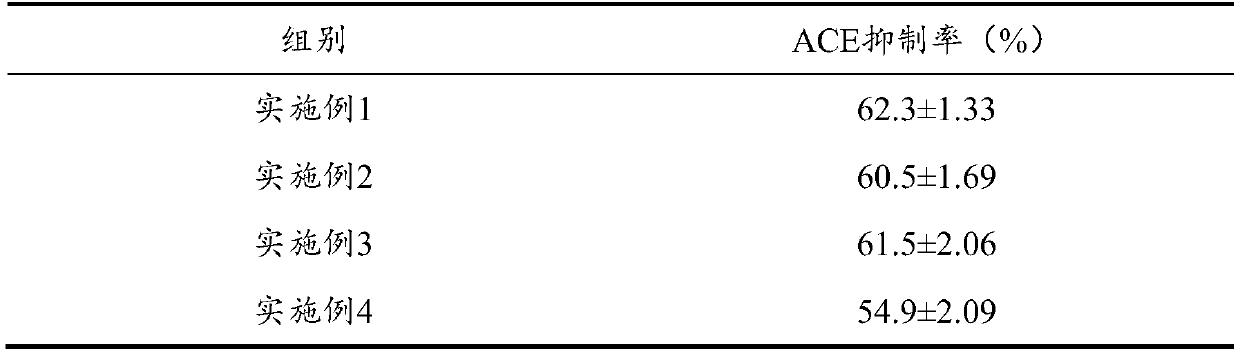

Examples

Embodiment 1

[0049] 1) Raw material homogenization and crushing: wash the tuna with clean water, remove internal organs and sediment, then add a certain amount of distilled water and stir evenly, and process it with a high-pressure homogenizer for 1 hour to obtain a homogenate.

[0050] 2) Fermentation and enzymatic hydrolysis: dilute to 10% solids concentration with culture medium, add 5% compound protease to the homogenate, inoculate Candida tropicalis (10%) at the same time, and ferment and enzymatically hydrolyze at 30°C for 72 hours.

[0051] 3) Centrifugation and high-temperature sterilization: high-temperature sterilization of the above-mentioned solution for 10-60 minutes, and centrifugation at 9000 rpm for 15-20 minutes after cooling.

[0052]4) Resin adsorption refining: put the concentrated absorption solution on the column equipped with macroporous adsorption resin, the amount of sample loading is the absorption solution equivalent to the weight of the resin; the flow rate of sa...

Embodiment 2

[0055] 1) Raw material homogenization and crushing: wash the tuna with clean water, remove internal organs and sediment, then add a certain amount of distilled water and stir evenly, and process it with a high-pressure homogenizer for 1 hour to obtain a homogenate.

[0056] 2) Fermentation and enzymolysis: Dilute with culture medium to a solid concentration of 8%, add 3% compound protease to the homogenate, inoculate Candida tropicalis at the same time, and ferment and enzymolyze at 35°C for 48 hours.

[0057] 3) Centrifugation and high-temperature sterilization: high-temperature sterilization of the above-mentioned solution for 10-60 minutes, and centrifugation at 6000°C for 15-20 minutes after cooling.

[0058] 4) Resin adsorption refining: put the concentrated absorption solution on the column equipped with macroporous adsorption resin, the amount of sample loading is the absorption solution equivalent to the weight of the resin; the flow rate of sample loading is controlled...

Embodiment 3

[0061] 1) Raw material homogenization and crushing: wash the tuna with clean water, remove internal organs and sediment, then add a certain amount of distilled water and stir evenly, and process it with a high-pressure homogenizer for 1 hour to obtain a homogenate.

[0062] 2) Fermentation and enzymolysis: Dilute with culture medium to a solid concentration of 15%, add 2% compound protease to the homogenate, inoculate Candida tropicalis at the same time, and ferment and enzymolyze at 25°C for 120 hours.

[0063] 3) Centrifugation and high-temperature sterilization: high-temperature sterilization of the above-mentioned solution for 10-60 minutes, and centrifugation at 5000-9000 rpm for 15-20 minutes after cooling.

[0064] 4) Resin adsorption refining: put the concentrated absorption solution on the column equipped with macroporous adsorption resin, the amount of sample loading is the absorption solution equivalent to the weight of the resin; the flow rate of sample loading is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com