Valve unit

A valve unit and valve seat technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of slow switching, shortening the service life of valve unit, limiting switching time, etc., to achieve the effect of small quality and ensure sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

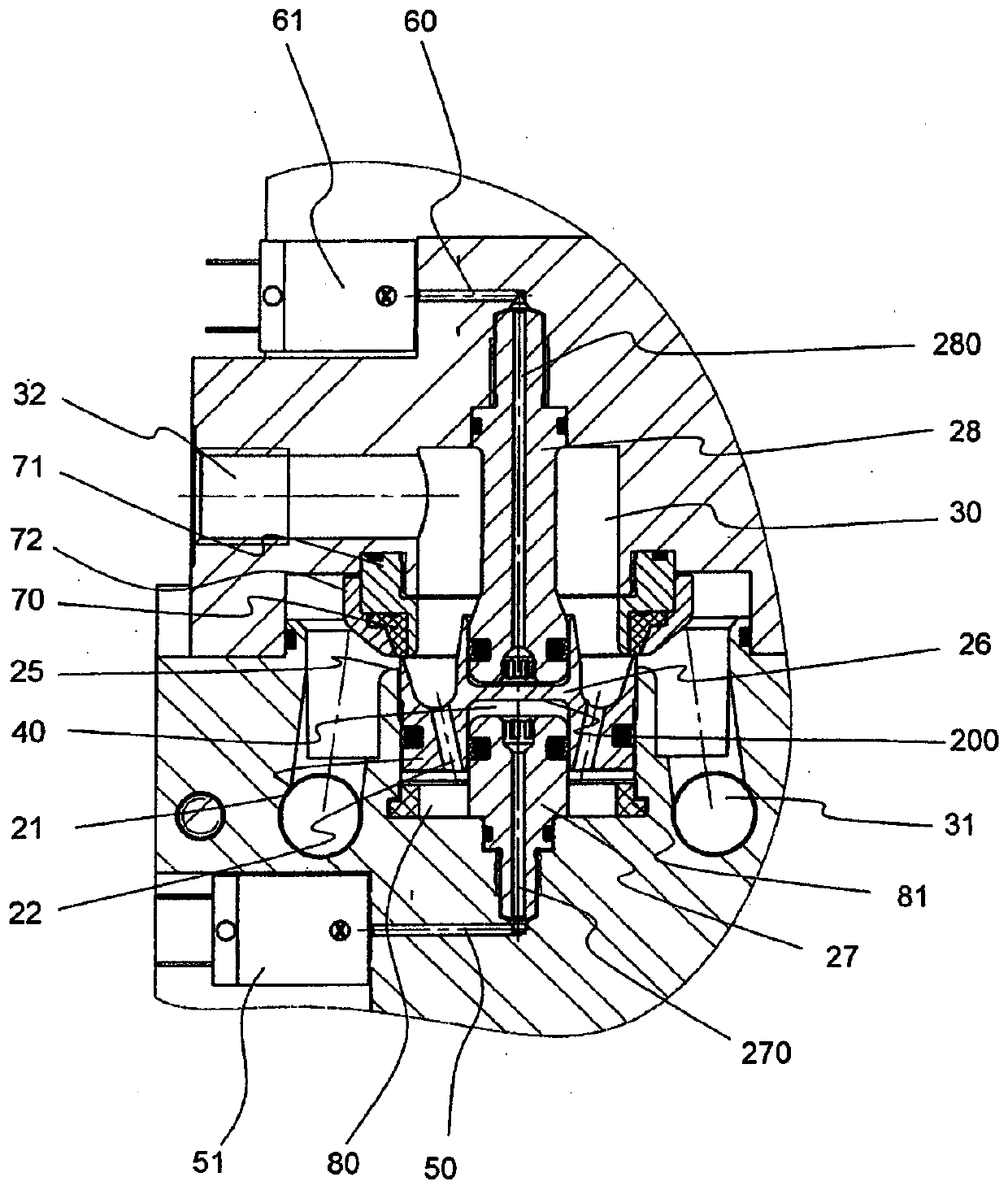

[0074] The second embodiment has the advantage that the service life of the valve unit is longer compared to the first example. The reproducibility of the switching movement is better so that the valve unit as a whole works more precisely.

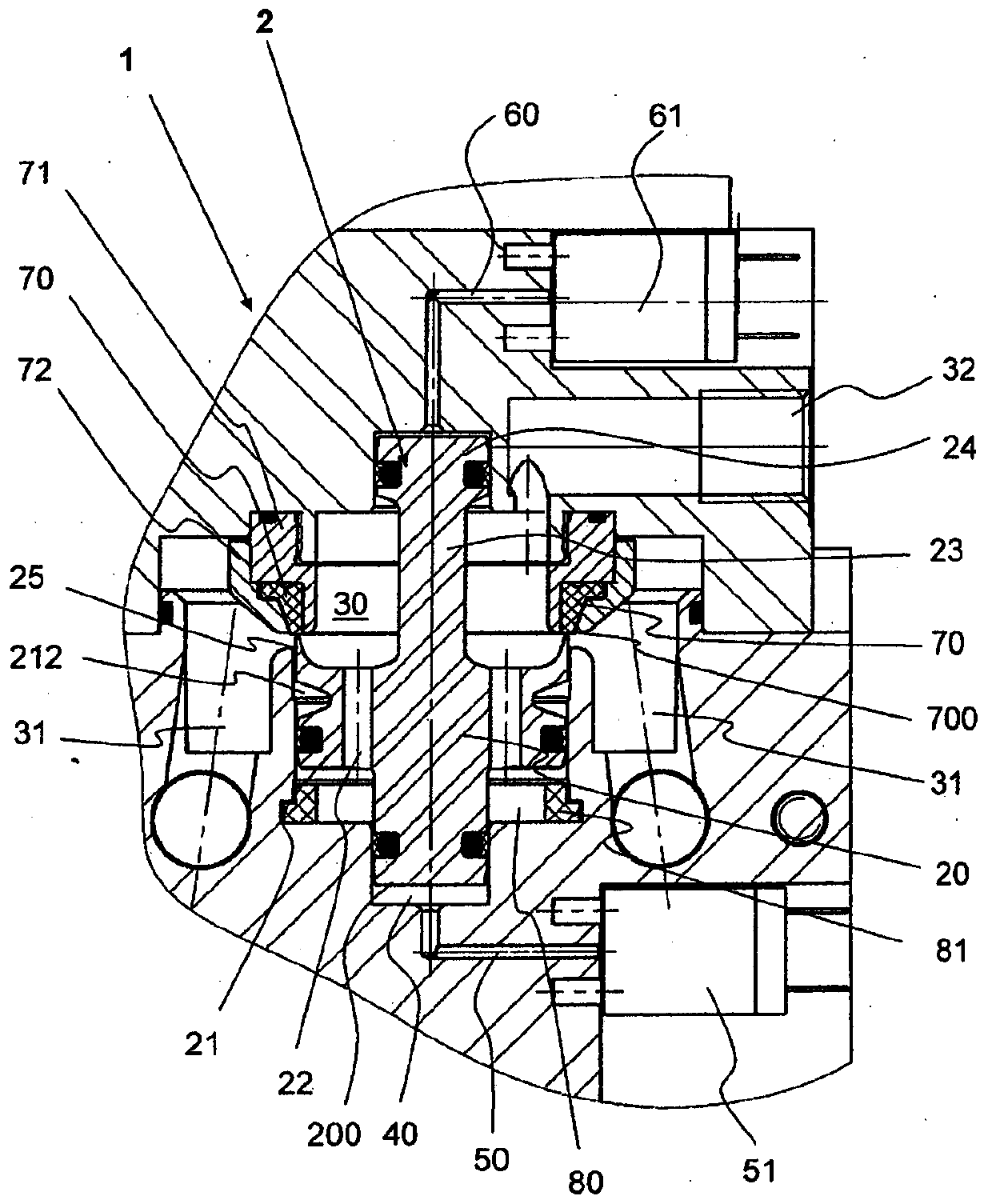

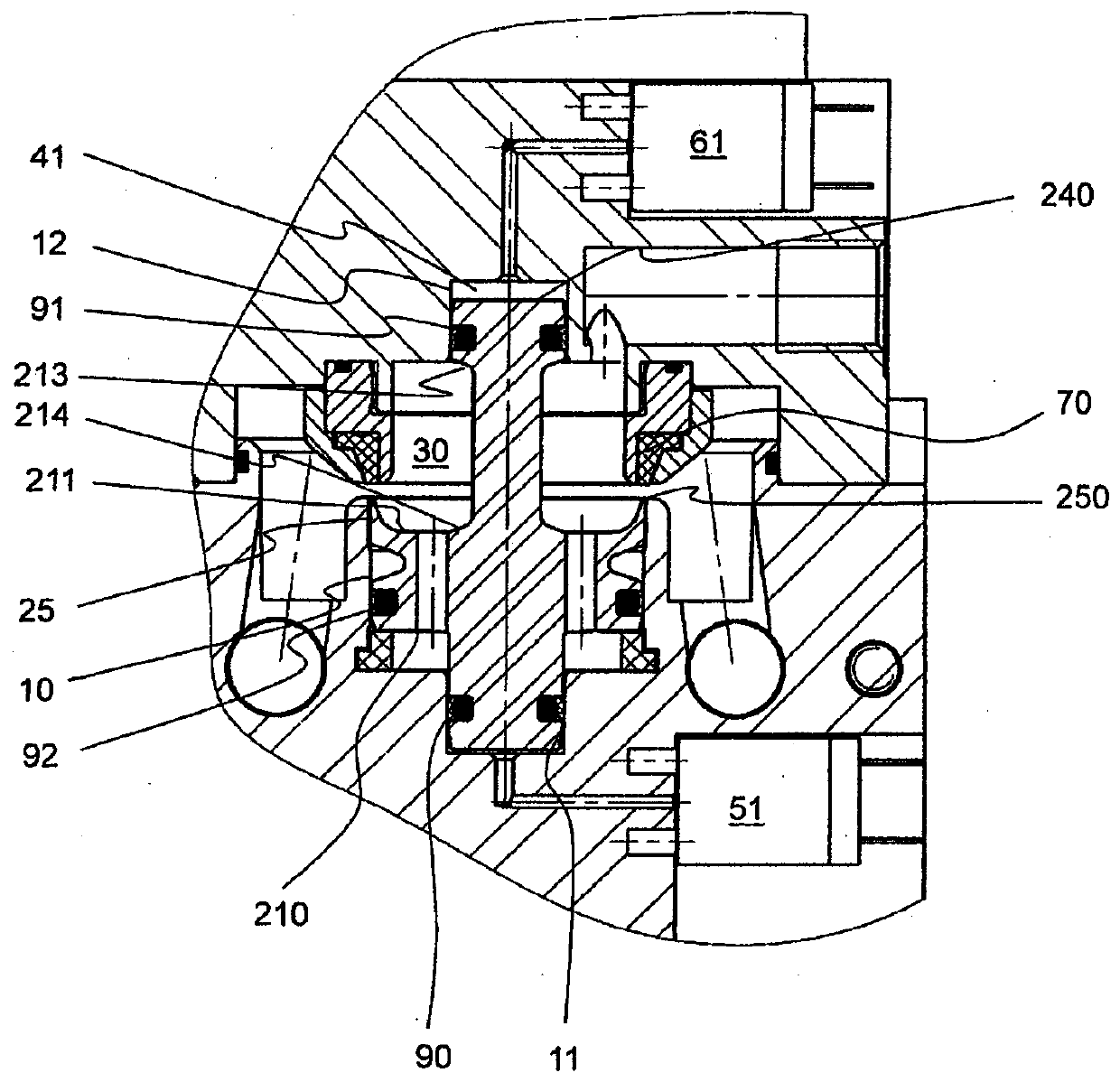

[0075] In the two embodiments described so far, the first control chamber 40 and the second control chamber 41 are formed cylindrically and are not divided. Furthermore, there are upper and lower dynamic control chamber seals 90 , 91 with the same guide diameter, between which a dynamic process seal 92 and a valve seal are arranged. Other settings are possible. Preferably, all embodiments described herein are bi-directional, ie, inputs and outputs are interchangeable.

[0076] In the previous examples, the guide diameter of the process seal 92 was greater than the guide diameter of the control chamber seals 90 , 91 , the guide diameter of the process seal being as large as the diameter of the sealing edge 250 .

[0077] in accordance wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com