Retaining Clips and Valves Equipped with Retaining Clips

A fixed clip and clamping technology, applied in the field of fixed clips, can solve the problems of high manufacturing cost, high time cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

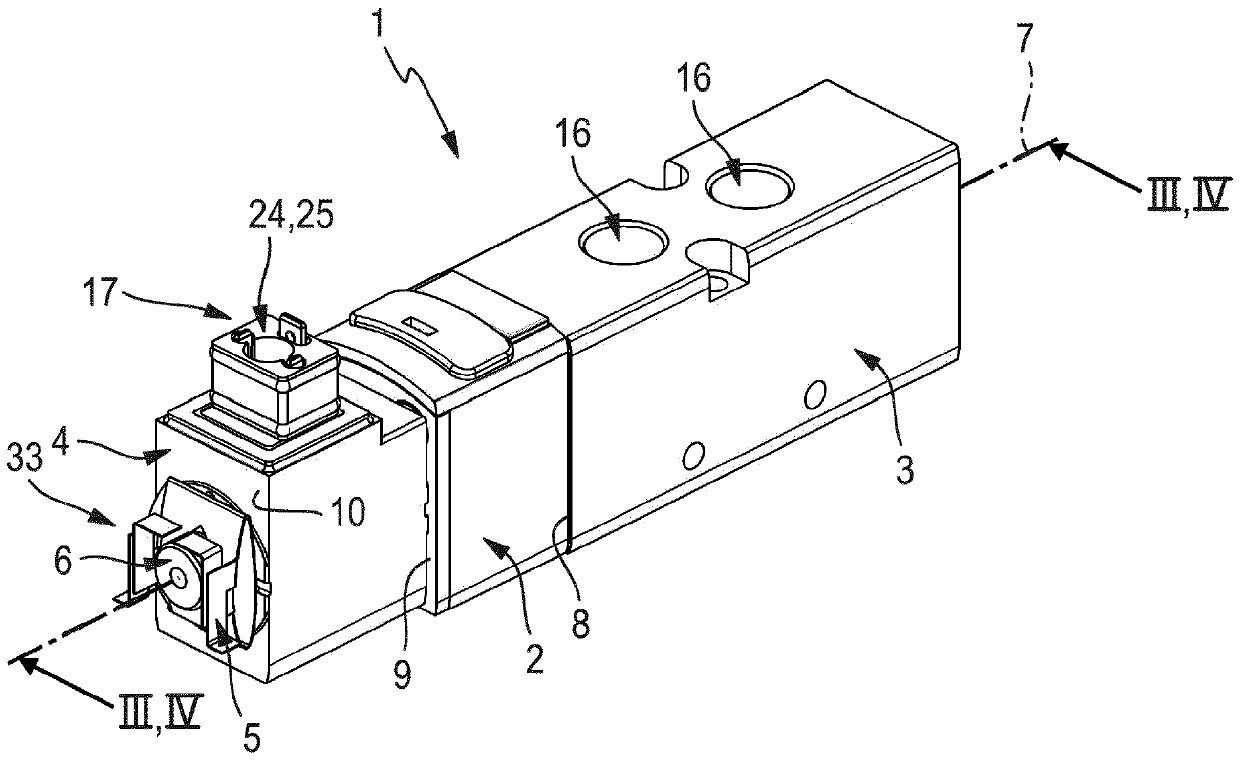

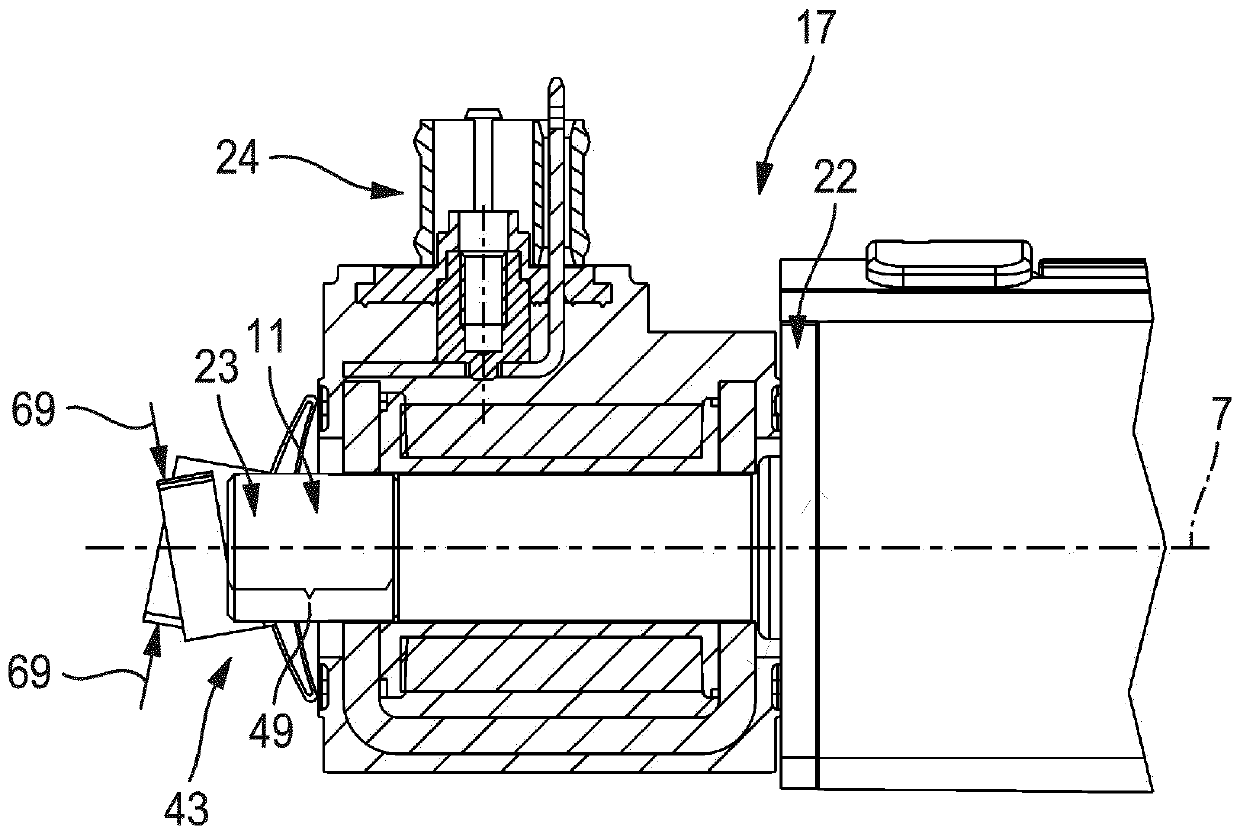

[0045] exist figure 1 In FIG. 1 , a valve designated with reference numeral 1 is shown in its entirety with a base section 2 and a main valve arrangement 3 , a magnetic coil unit 4 and a retaining clip 5 . The base section 2 is preferably detachably mounted on the end side 8 of the main valve device 3 . Starting from a base end face 9 of the base section 2 opposite the end face 8 of the main valve arrangement 3 , the armature tube 6 extends axially along the reference axis 7 . In this case, the magnetic coil unit 4 is pushed axially onto the armature tube 6 so that it bears against the base end face 9 of the base section 2 .

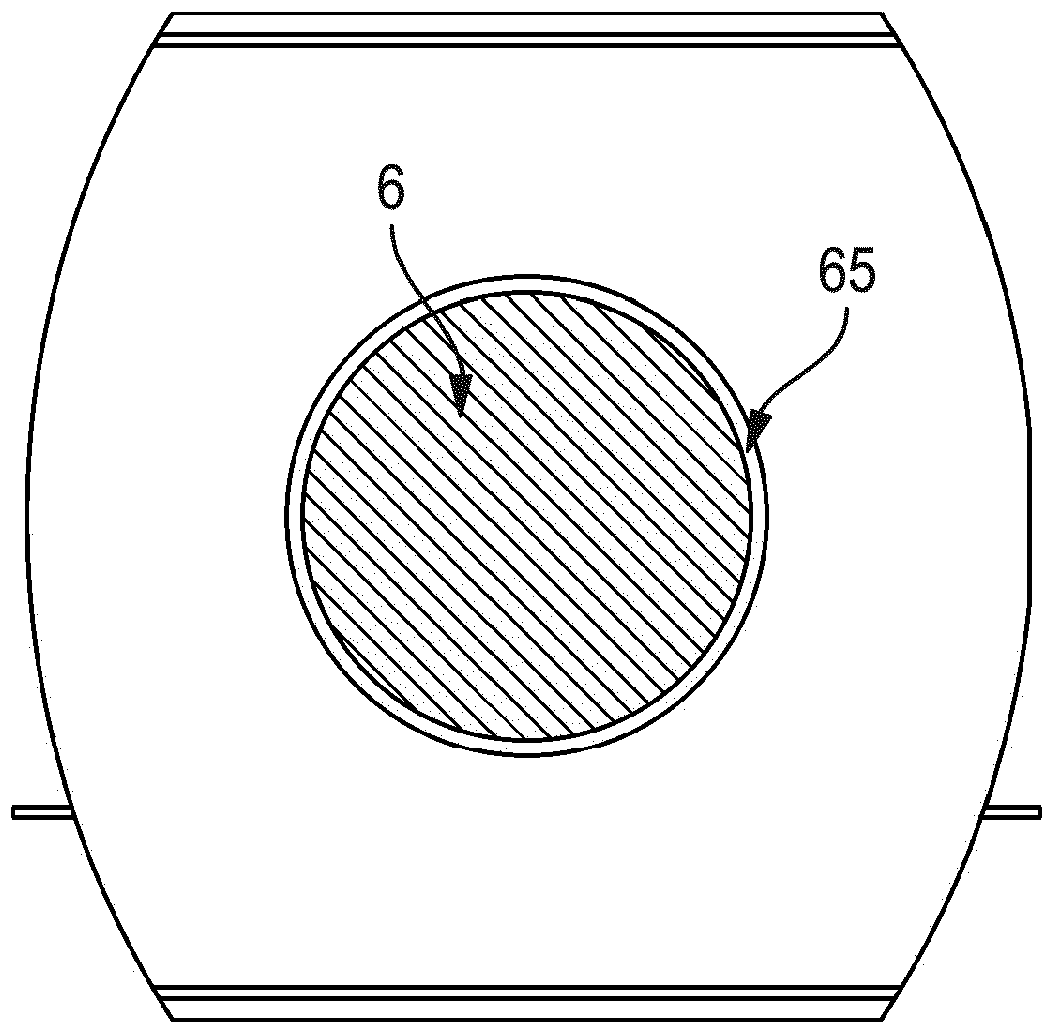

[0046] The armature tube 6 has a free end section 11 opposite the base section 2 , with which the armature tube 6 protrudes beyond the pushed-on magnetic coil unit 4 . The fastening clip 5 is inserted onto this free end section 11 so that the fastening clip 5 is pressed against the magnetic coil unit 4 facing the free end section 11 of the armature tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com