A pneumatic high pressure switch

A pneumatic high-voltage switch technology, which is applied to electric switches, power devices inside switches, electrical components, etc., can solve problems such as workers' dangers, and achieve reliable electrical contact surfaces, high pressure per unit area, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

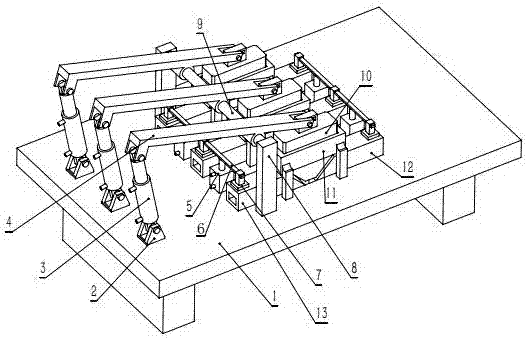

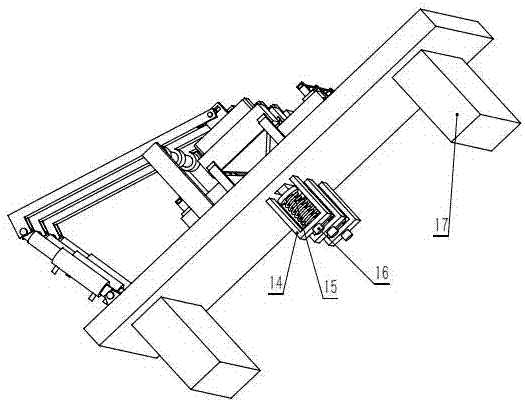

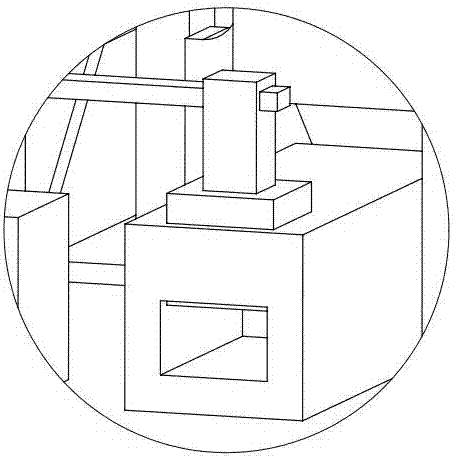

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a pneumatic high-voltage switch includes a base plate 1, a hinge support 2, a first cylinder 3, a lever 4, a second cylinder 5, a cross bar 6, a pressure block 7, a bracket 8, a support shaft 9, and a V-shaped conductive block. 10. Guide frame 11, input terminal 12, output terminal 13, fixed frame 14, compression spring 15, thimble 16, characterized in that: the bottom plate 1 is a rectangular insulating plate, and a rectangular slot, three input terminals 12 and three output terminals 13 are arranged on both sides of the rectangular slot, and the end of the input terminal 12 and output terminal 13 close to the rectangular slot is processed into a chamfer of 45 degrees, A crimping hole with a rectangular cross-section is provided at one end away from the rectangular groove, and a square chute is vertically set above the crimping hole. The briquetting block 7 is slidably installed in the square chute, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com