High-conversion-efficiency photovoltaic module and manufacturing method

A photovoltaic module and high-conversion technology, applied in the solar field, can solve problems such as difficulty in upgrading, limited space for cell efficiency improvement, and reduction in module conversion efficiency, and achieve the effect of simplifying connection methods, reducing ineffective areas, and improving overall conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the technical characteristics and content of the present invention, the detailed technical description of this patent is as follows:

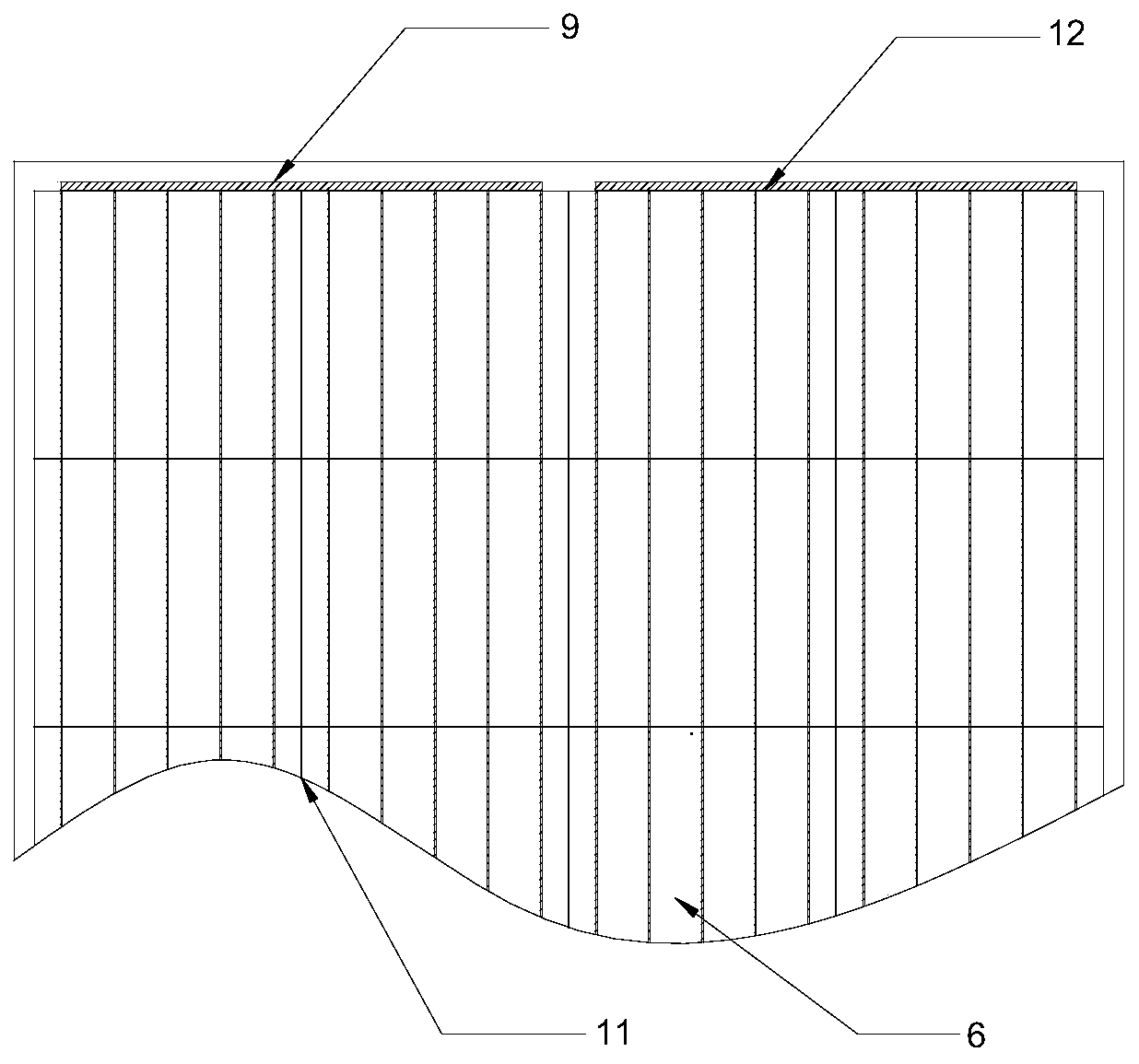

[0024] like figure 1 and figure 2 As shown, a high conversion efficiency photovoltaic module in the present invention includes a front cover plate 1, a front encapsulation layer 2, a solar cell layer 3, a back encapsulation layer 4 and a back cover plate 5 arranged in sequence from top to bottom, The solar cell sheet layer 3 includes several solar cell strings 6, and each group of solar cell strings includes several solar cell sheets 7 connected by first conductive members 8, and the solar cell strings are connected by second conductive members 9, so A first insulating member 10 is provided between the solar cells, a second insulating member 11 is provided between the solar cell strings, and a third insulating member 12 is provided between the solar cell strings and the second conductive member.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com