Concrete uniaxial tensile test fixture and test method

A technology of uniaxial tension and test fixture, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., and can solve the problems of concrete specimen fracture, tensile test failure, and creep damage of the contact part of the fixture etc. to achieve the effects of reducing damage, improving accuracy, and dispersing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

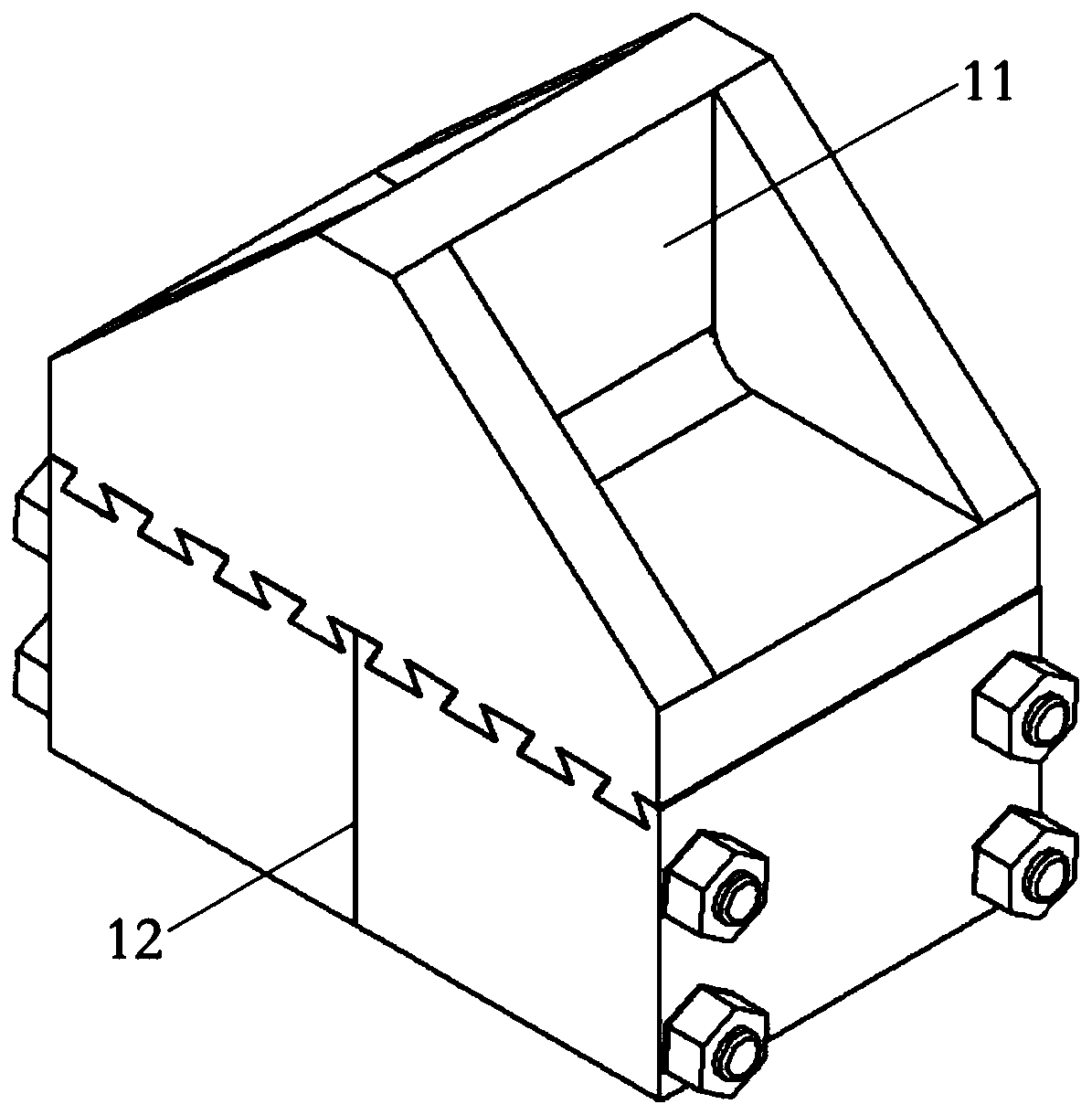

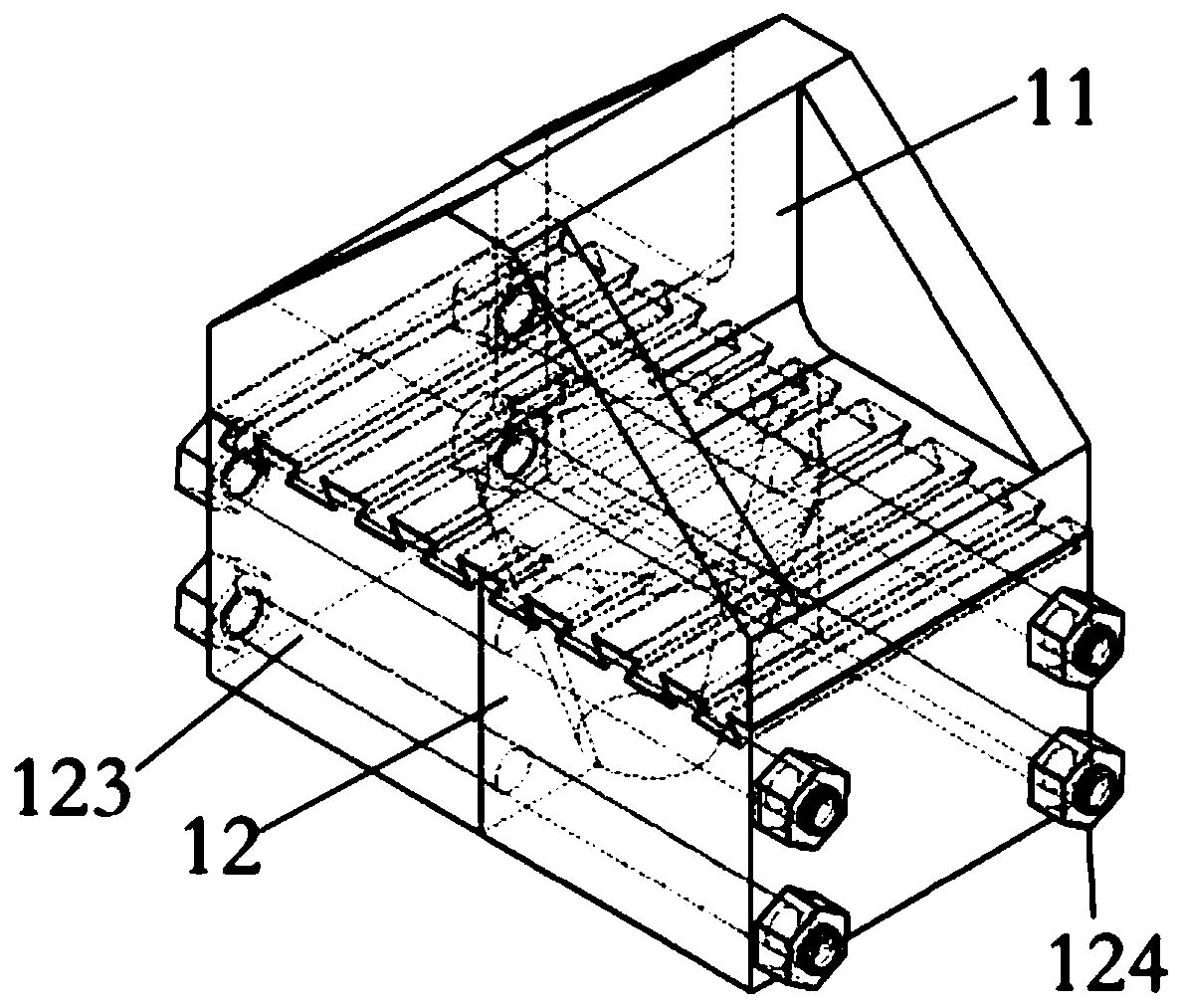

[0062] This embodiment provides a concrete uniaxial tensile test fixture, including two clamp bodies 1 with the same structure, the two clamp bodies 1 are respectively arranged at the two ends of the concrete specimen 2, and the concrete specimen 2 is fixed by the clamp body 1 Fixed installation on the tensile testing machine.

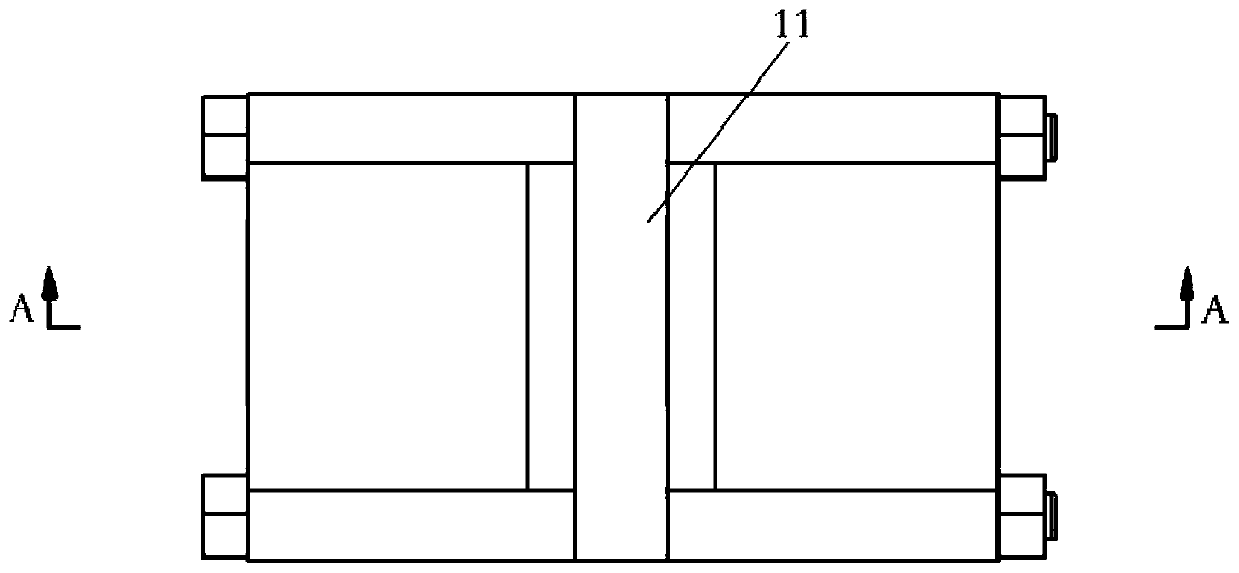

[0063] The clamp body 1 includes a jaw connector 11 and a specimen holder 12, one end of the jaw connector 11 is connected with the jaw of the tensile testing machine, and the other end is connected with the specimen holder 12; the jaw connector 11 and the specimen holder 12 are connected by tenon and tenon; the clamping end of the concrete specimen 2 is embedded in the specimen holder 12, and the clamping end of the concrete specimen 2 and the specimen They are connected by surface contact and tight fit.

[0064] The jaw connector 11 includes a connector bottom plate 111, a connector middle plate 112 and two sets of ribs 113; the connector middle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com