A detection method for flange bolt looseness based on electromechanical impedance

A flange bolt, electromechanical impedance technology, applied in the field of non-destructive testing, can solve the problem of time-consuming and labor-intensive monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

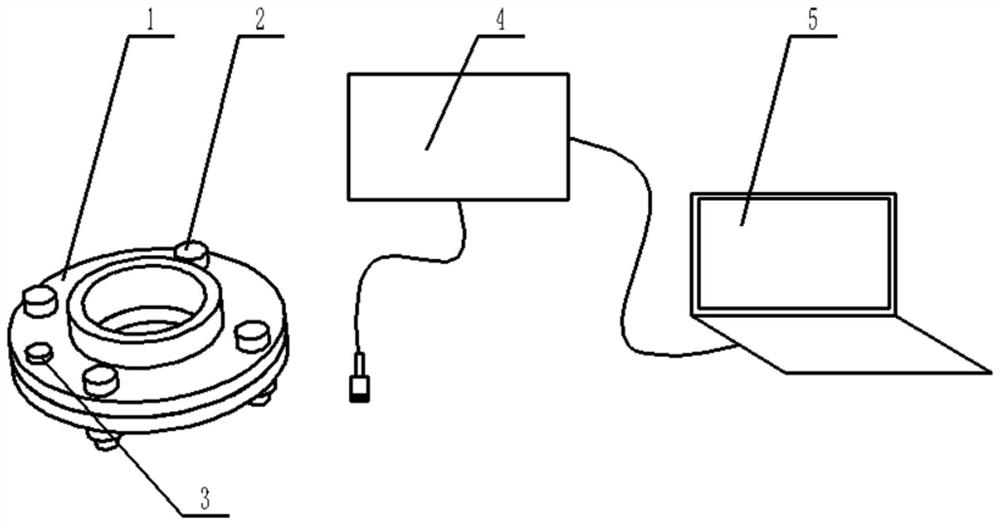

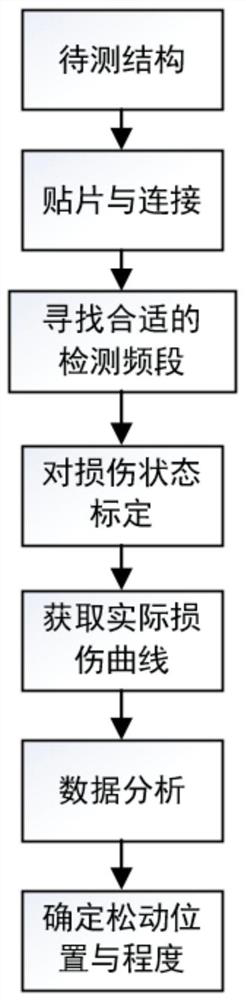

[0028] The specific embodiment of the present invention will be further described below by taking a certain type of four-bolt transmission shaft connecting flange as an example.

[0029] Step 1, preparation work:

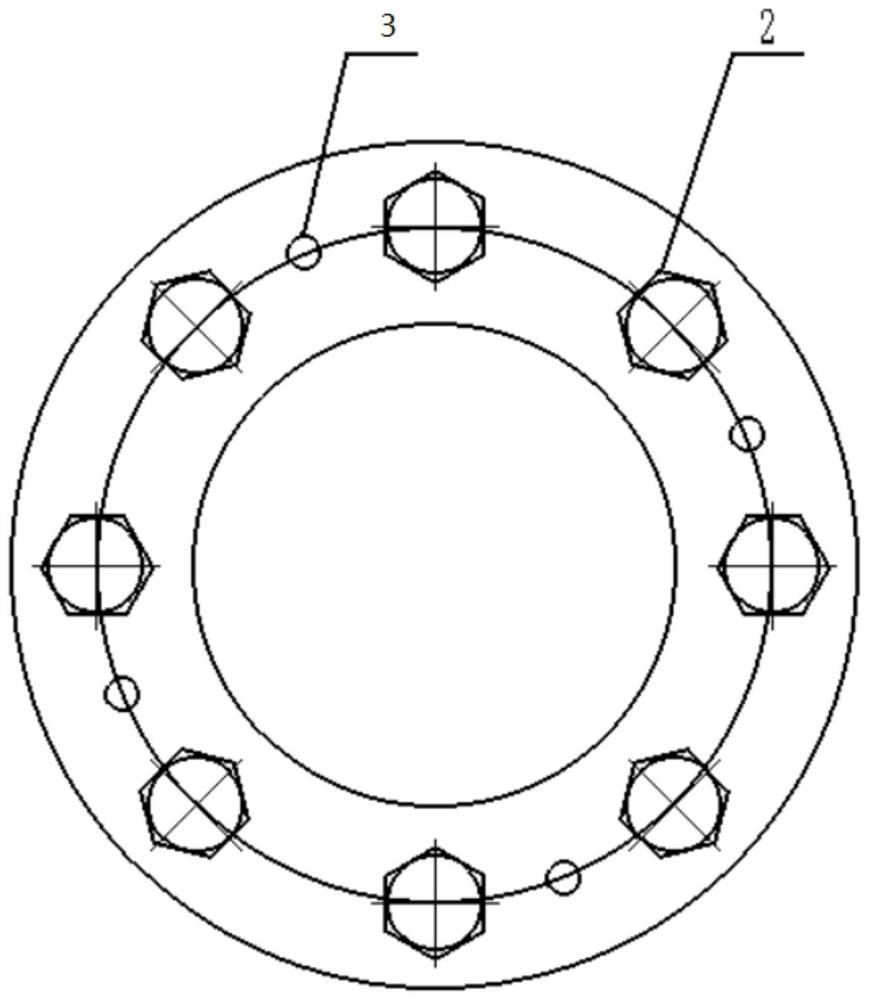

[0030] 11. Evenly install the piezoelectric ceramic sheet on the front of the connecting flange. The installation rule is to install on the flange surface in the middle of every two bolts. The installation method is glued.

[0031] 12. Place the flange evenly on a flat surface.

[0032] 13. Select one of the piezoceramics as the calibration piezoceramic in the next step, and connect the impedance analyzer to the piezoceramic.

[0033] Step 2, find the appropriate detection frequency band of the test piece to be tested:

[0034] 21. Define the two near-field bolts next to the calibrated piezoelectric ceramic sheet as near-field bolts. Tighten the two near-field bolts to 60N·m, and keep the other bolts loose.

[0035] 22. Define the bolts distributed on the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com