Domestic rubbish disposal system and method based on pyrolysis gasifier and tunnel brickkiln

A technology for pyrolysis gasification and domestic waste, which is applied in waste heat treatment, incinerators, combustion methods, etc., can solve the problems of low secondary pollution, odorous air pollution, environmental damage, etc. The effect of reducing the British content and toxic equivalent, improving the efficiency, and suppressing the emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

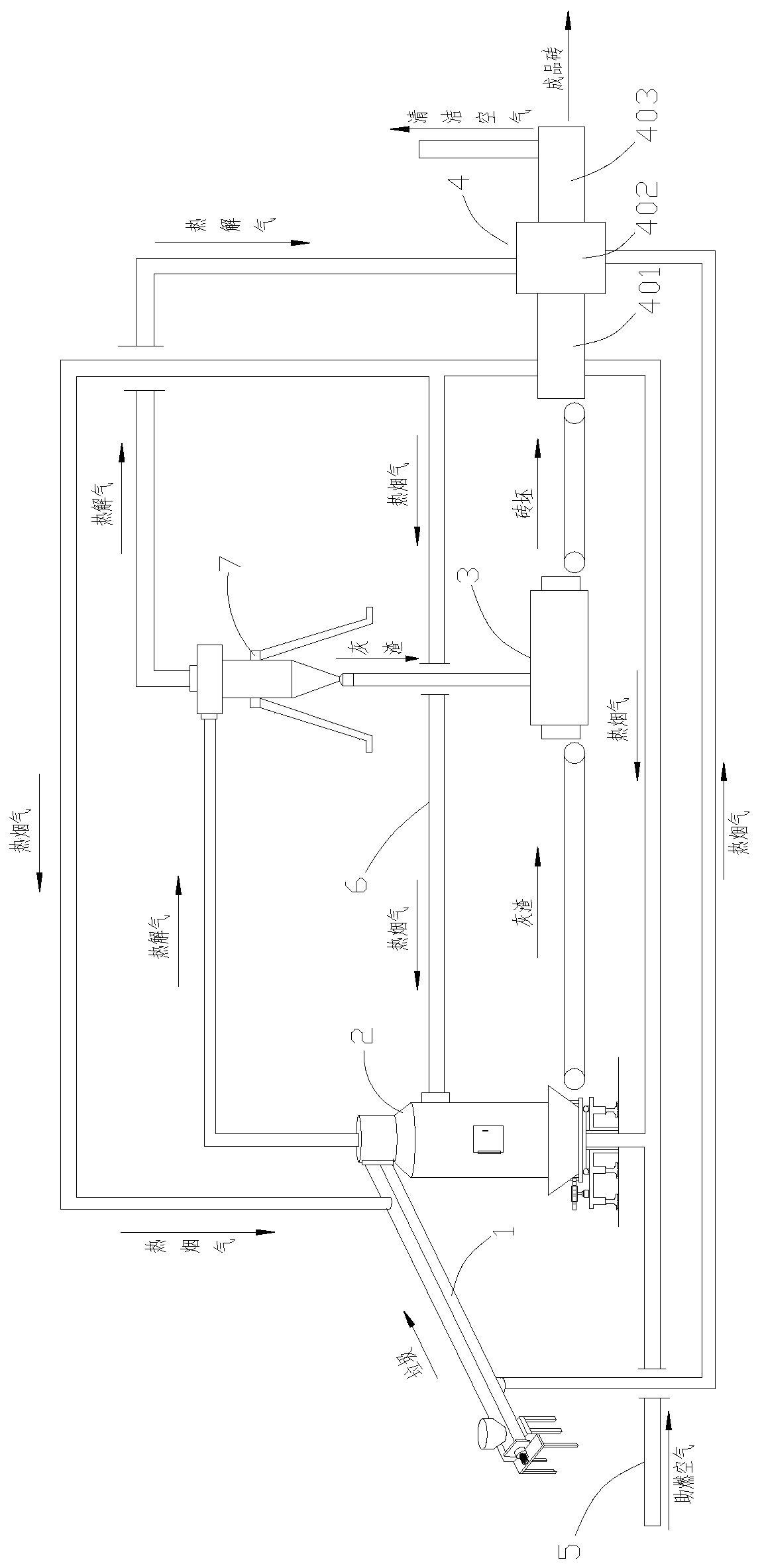

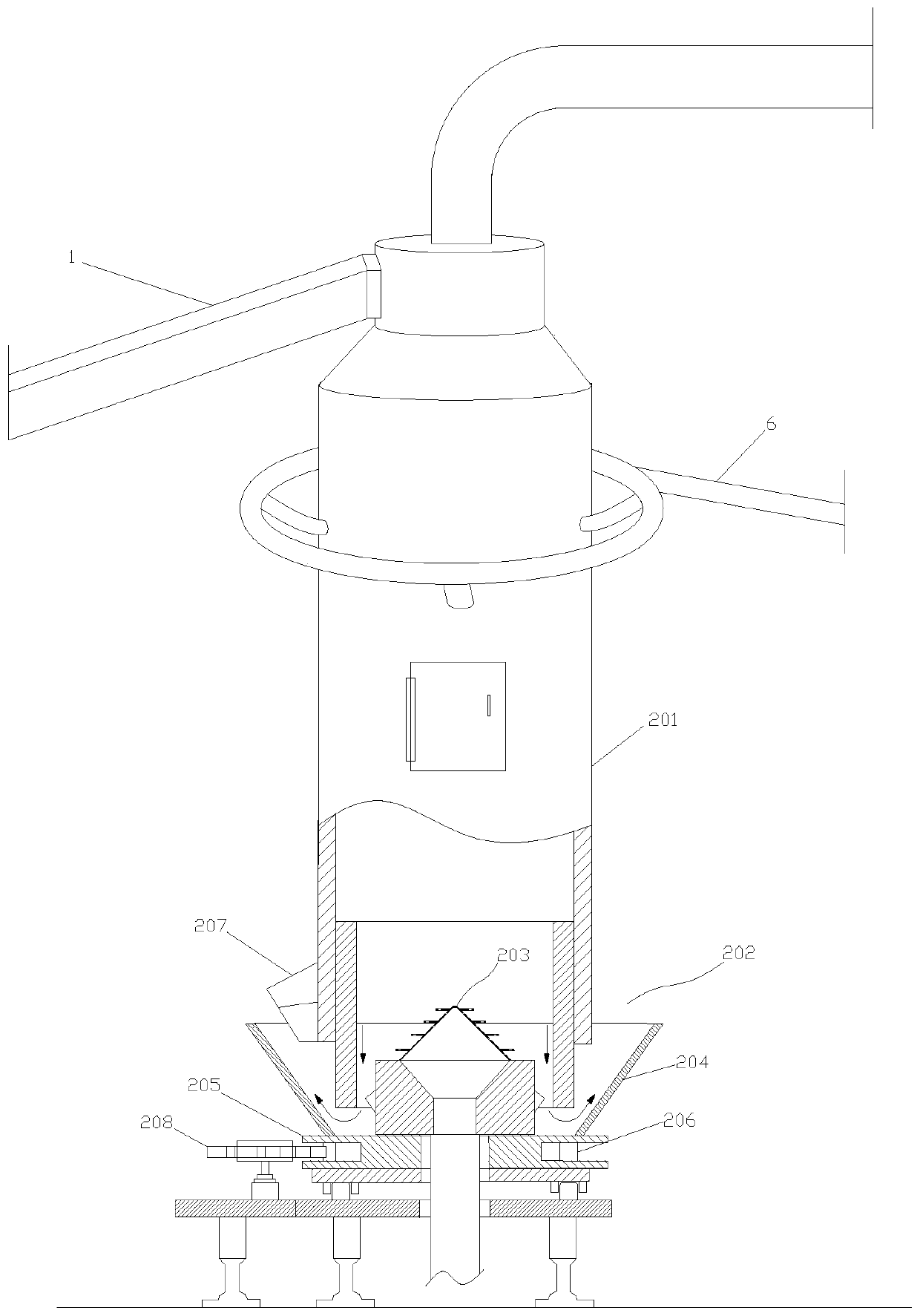

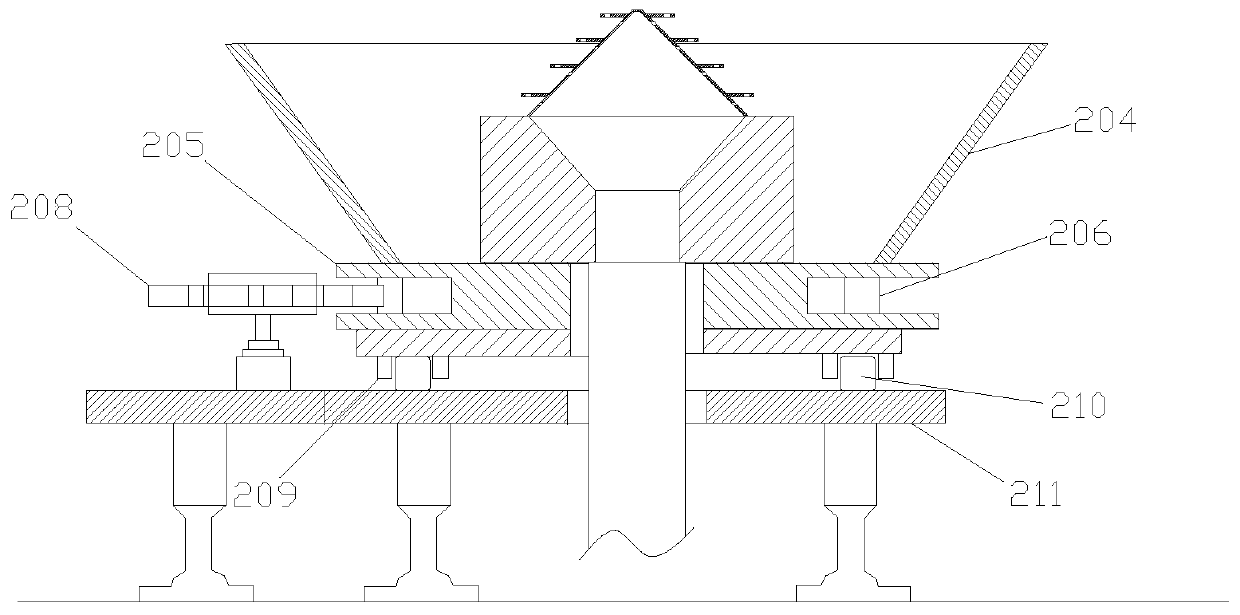

[0034] like figure 1 As shown, the present invention firstly provides a domestic waste treatment system based on a pyrolysis gasifier 2 and a tunnel brick kiln, including a feeding drying device 1, a pyrolysis gasifier 2, a brick making system 3 and a tunnel kiln 4. The feed port of the pyrolysis gasifier 2 corresponds to the discharge port of the feeding drying device 1, and the feed port of the brick making system 3 corresponds to the slagging port of the pyrolysis gasifier 2, so The feed port of the tunnel kiln 4 corresponds to the discharge port of the brick making system 3, wherein the tunnel kiln 4 includes a preheating section 401, a combustion section 402 and a cooling section 403, and the first sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com