Method for adjusting steam injection mode in steam huff-puff process

An adjustment method and steam injection technology, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of less oil production, uneven steam absorption, and poor recovery effect of heavy oil, so as to improve oil and gas production. Ratio, increase the degree of mobilization, and improve the effect of uneven steam absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for adjusting the steam injection mode in the process of steam stimulation,

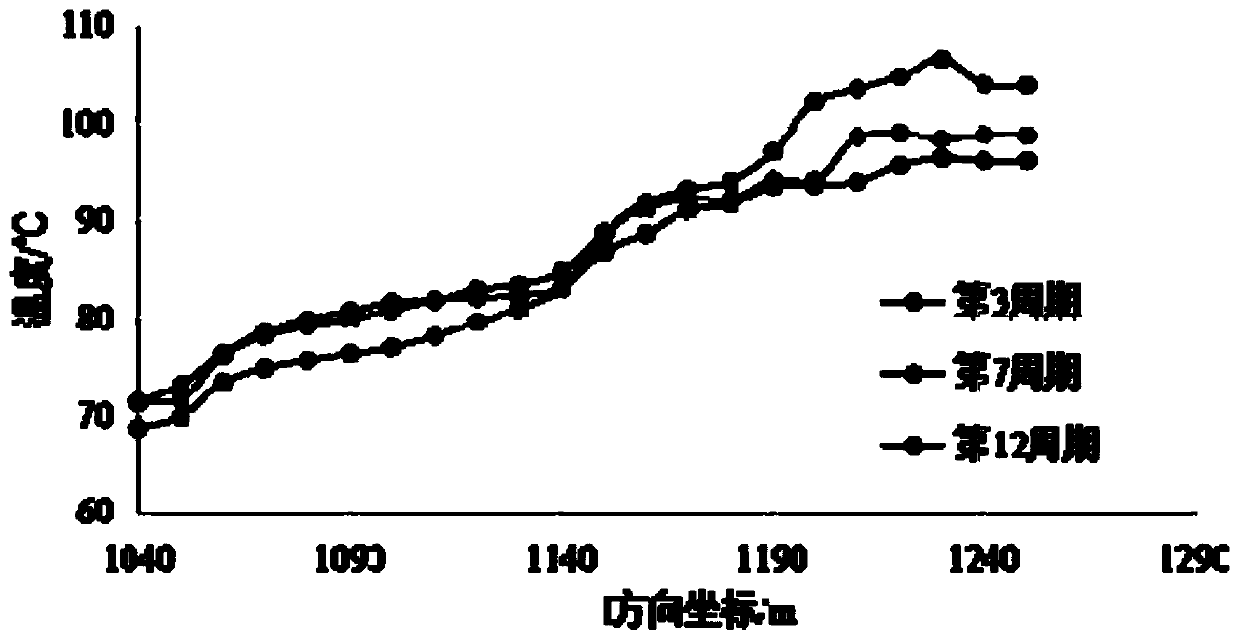

[0054] 1) The heterogeneous reservoir has serious uneven steam absorption, and the horizontal well section has high oil saturation. (Extreme difference in oil saturation R=So max -So min , where, So max is the maximum oil saturation in the region, So min is the minimum oil saturation in the region. ) If the coefficient of variation of formation permeability is 0.27, the horizontal well injects steam at 290m 3 / d, under the conditions of temperature 250°C and steam dryness 0.7, such as figure 1 As shown, after the end of the third period, the temperature in the low-permeability zone at the front end of the horizontal well is relatively low, and the temperature in the rear-end high-permeability zone is relatively high. The phenomenon of uneven steam absorption in periodic horizontal well sections is more obvious, and the steam absorption profile becomes more and more irregular; te...

Embodiment 2

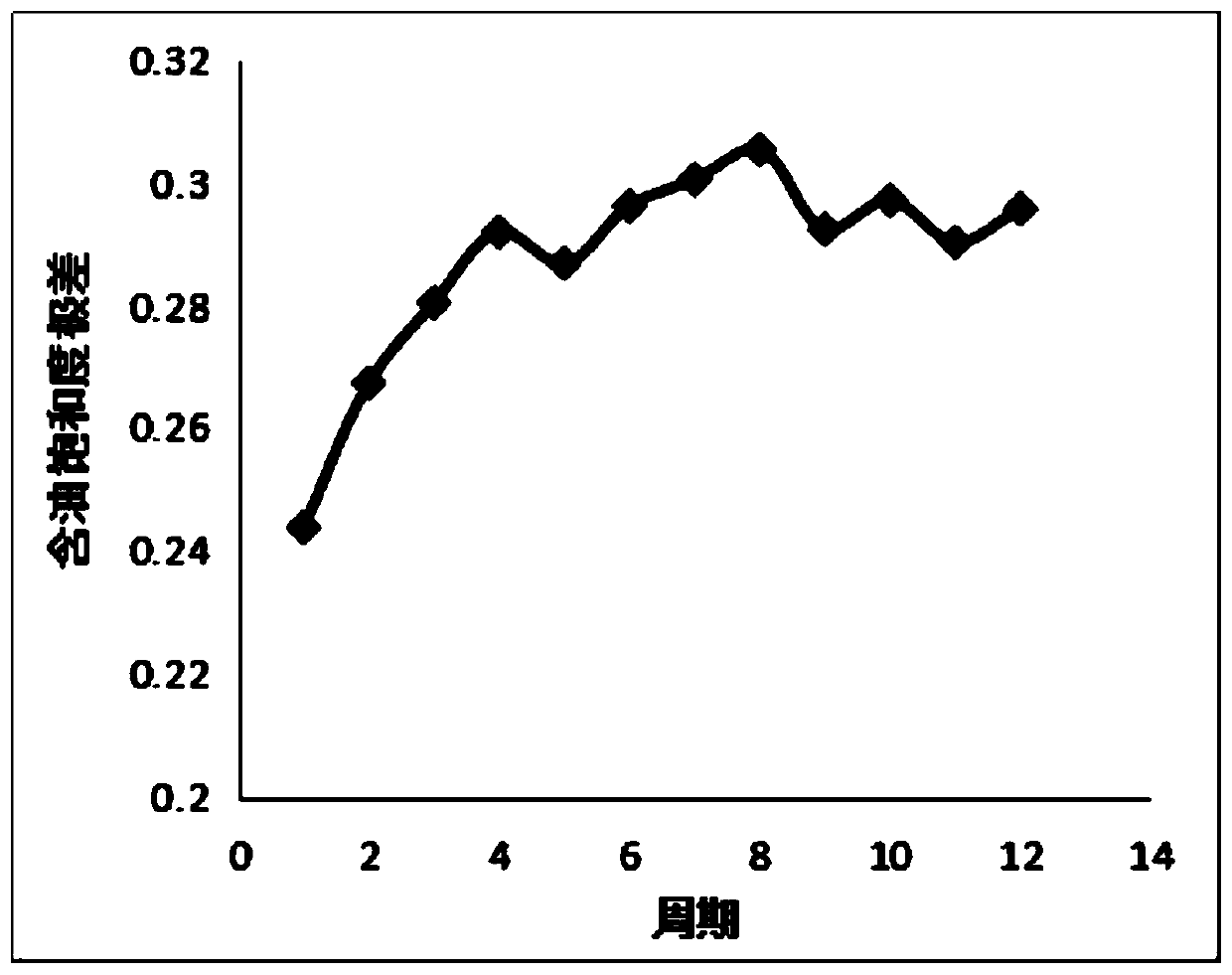

[0067] When the stratum heterogeneity increases, V k =0.74, horizontal well steam injection 290m 3 / d, under the conditions of temperature 250°C and steam dryness 0.7, the coefficient of variation of temperature is higher than that of the previous situation, but the overall change has the same trend. The oil in the reservoir is produced in large quantities, the water saturation gradually increases, and the effect of the back-end steam heating the formation becomes smaller. As the front-end temperature rises, the temperature variation coefficient gradually decreases. Such as Figure 11 , the steam huff and puff began to decline in the second period, and after two consecutive periods of decline, the temperature coefficient of variation reached a minimum value in the fourth period. The coefficient of variation of temperature in the fourth cycle is 11.96, and that in the fifth cycle is 12.

[0068] The best adjustment time should be when the temperature variation coefficient ...

example

[0072] Oilfield 1 reservoir has a burial depth of 950m, oil layer thickness of 8m, average porosity of 40%, average permeability of 5000mD, initial oil saturation of 0.6, formation heterogeneity, crude oil viscosity of 2×10 under oil layer conditions 4 mPa.s, the original reservoir pressure is 9.5MPa.

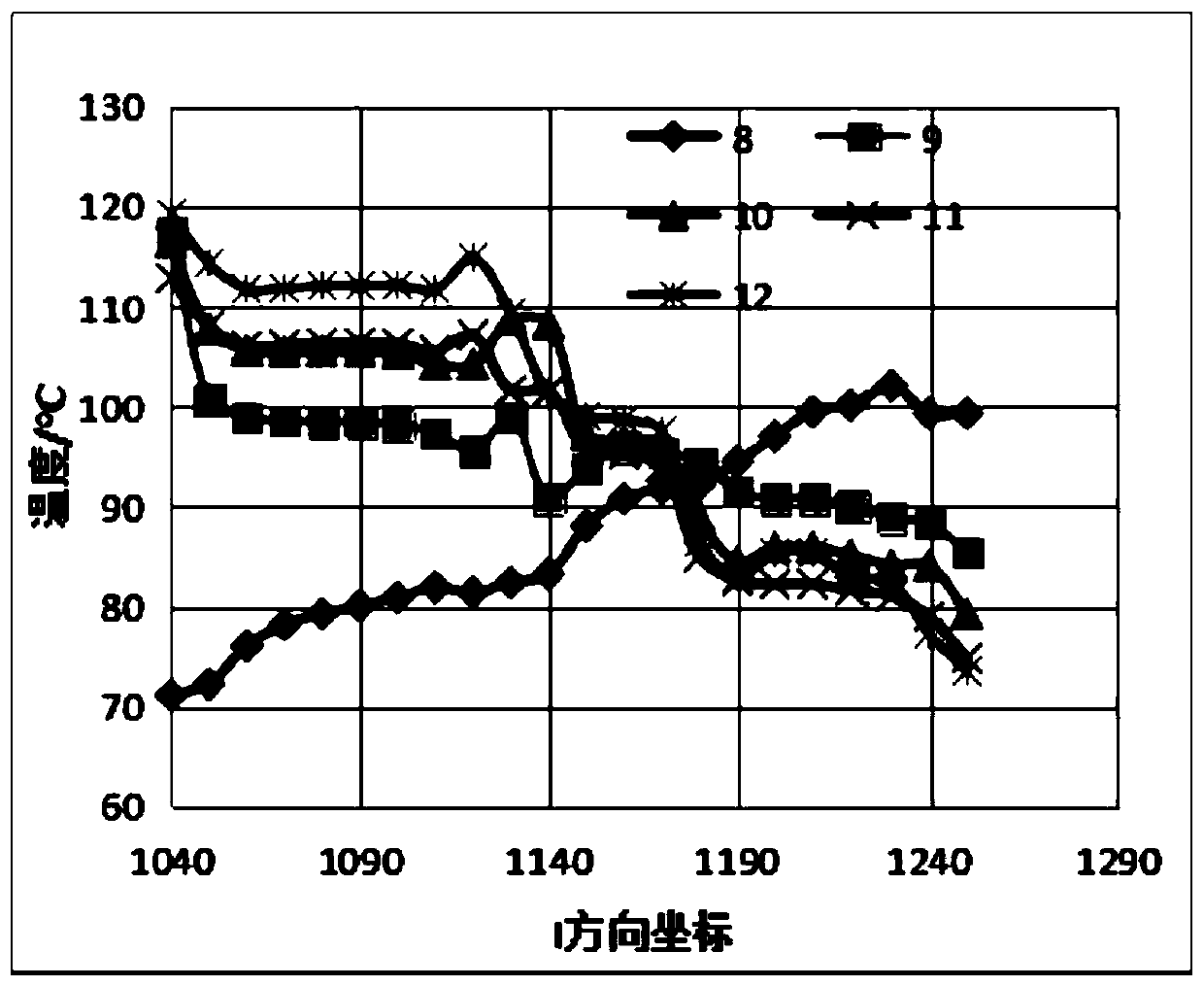

[0073] A horizontal well in the oil layer has 14 cycles of steam huff and puff, and the daily oil production reaches its peak and then continues to decline (the daily oil production peak is in the first cycle), from the analysis of the temperature profile test curve ( Figure 13 ) found that the second half of the well at 1180-1260m had good steam absorption and high recovery, while the first half of the well had poor steam absorption and low recovery, and the horizontal well had serious uneven steam absorption. The coefficient of temperature variation dropped continuously after reaching the maximum value at the end of the sixth cycle, dropped to 6.72 at the end of the 13th cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com