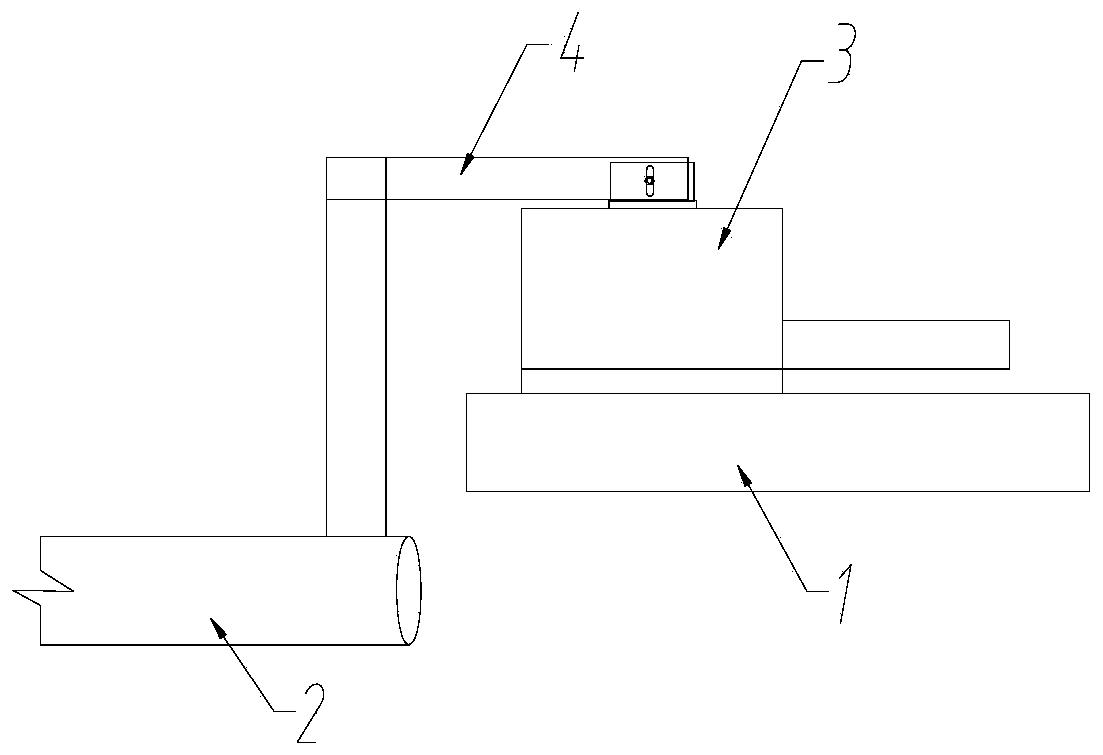

Positioning tension device for mounting steel structural member

A technology of tensioning device and steel structure, which is applied in the field of positioning and tensioning device for the installation of steel structure components, and can solve problems such as inability to guarantee welding quality, investment in multiple measures, and increasing the lifting weight of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

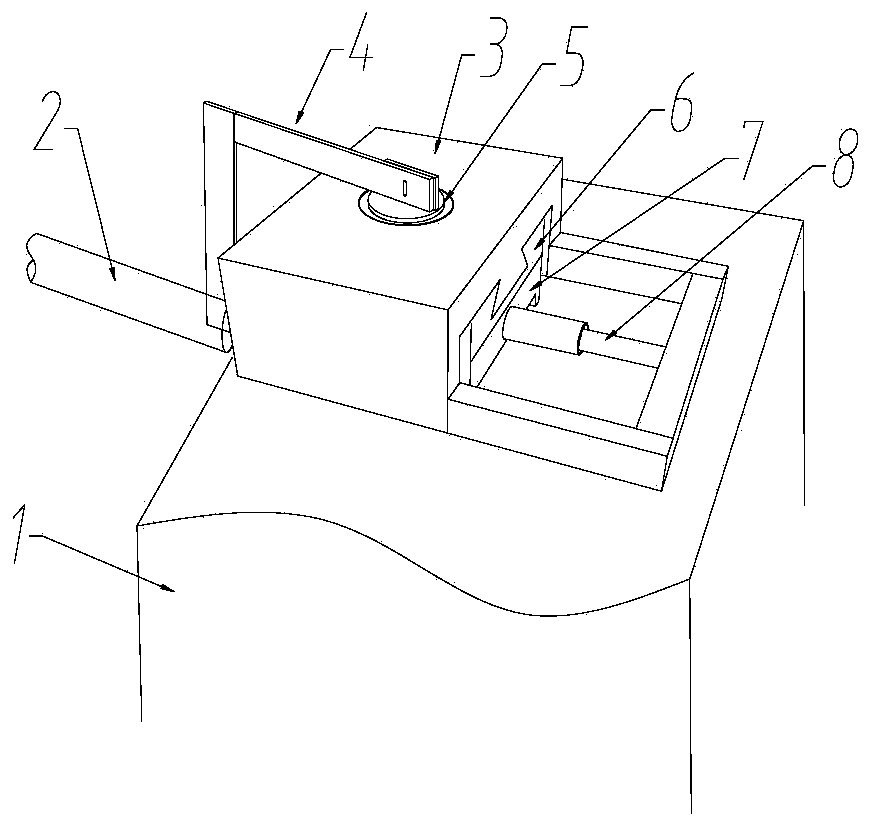

[0033] Example 1: Reference image 3 and Figure 4 , the welding base 7 is concave, and the welding base 7 is buckled upside down on the fixed steel structure (that is, the fixed steel structure 1), and the two sides of the concave shape are fixedly connected with the fixed steel structure 1, and the fixed connection at this position can be welding.

example 2

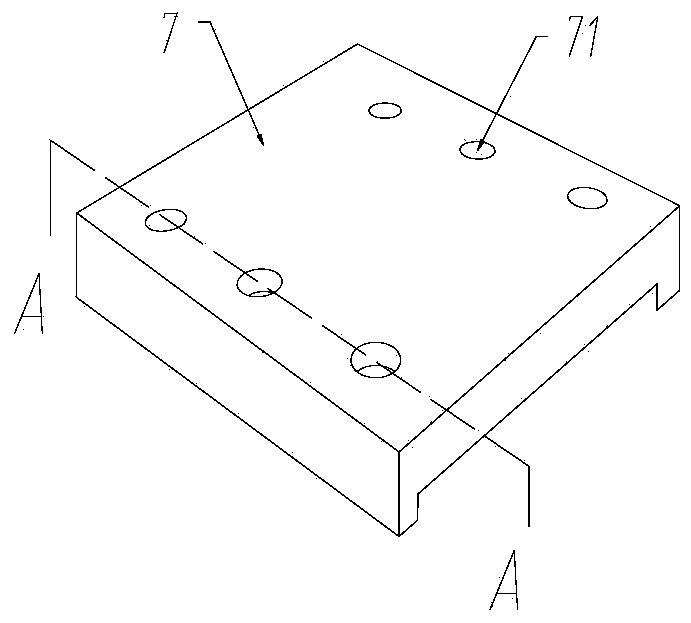

[0034] Example 2: Reference Figure 5 and Image 6 As shown, the connection between the dismountable base 6 and the welded base 7 is connected by bolts. Specifically, six threaded holes 71 are arranged on the upper part of the welded base 7, and six countersunk holes are arranged on the positions corresponding to the six threaded holes on the disassembled base 6. 61, just disassemble base 6 and welding base 7 bolts are hinged by countersunk head bolts.

example 3

[0035] Example 3: The groove 62 on the top of the disassembly base 6 is a through chute with a dovetail-shaped cross section, and the slide rail 32 at the bottom of the sliding block 3 and a long protruding slide rail with a dovetail-shaped cross-section. In this example, the sliding block 3 slides in translation on the dismountable base 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com