Film for antibacterial packaging bag and preparation method thereof

A packaging bag and film technology, which is applied in the field of film for antibacterial packaging bags and its preparation, can solve the problems of high cost, poor mechanical properties, and injury to pregnant women, and achieve low production cost and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

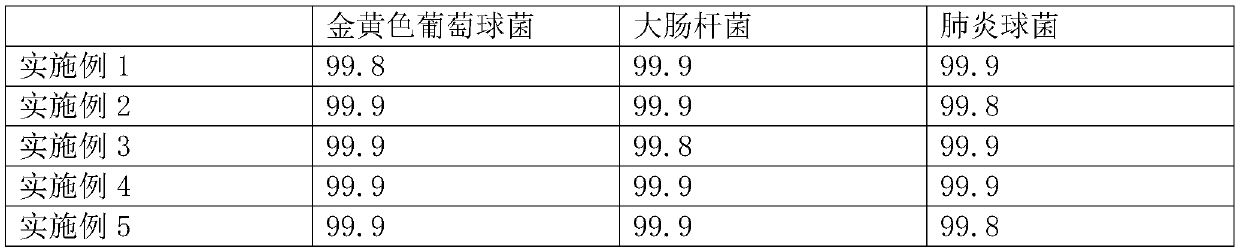

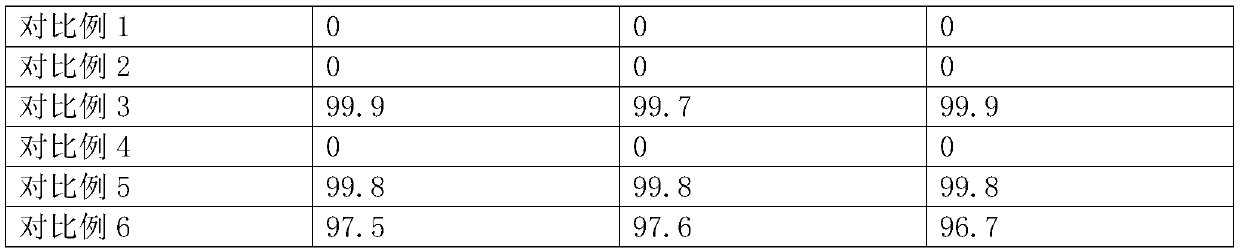

Examples

Embodiment 1

[0042] A film for antibacterial packaging bags is prepared by mixing the following components in parts by mass:

[0043] 10 parts of low-density polyethylene;

[0044] 45 parts of high-density polyethylene;

[0045] 8 parts of maleic anhydride grafted polyethylene;

[0046] 18 parts of thermoplastic polyurethane elastic rubber;

[0047] 3 parts of filler;

[0048] 12 parts of nano zinc oxide-chitosan composite antibacterial agent.

[0049] The filler in this embodiment is 2000 mesh calcium carbonate.

[0050] A preparation method of a film for an antibacterial packaging bag, comprising the following steps:

[0051] Step 1, be 90% with deacetylation degree, the chitosan raw material that molecular weight is 500kDa is dissolved in solid content and is 2% styrene-acrylic acid ester aqueous solution, drops into 1M sodium hydroxide solution and adjusts PH to alkalescence to water bath, obtains For the blended solution, the quality of the chitosan raw material accounts for 1% of...

Embodiment 2

[0055] The preparation method of this embodiment and embodiment 1, the proportioning of each component is basically the same, and the filler of this embodiment is the blend that zinc stearate, calcium carbonate mix according to mass ratio 1:1. Zinc stearate needs to pass through the molecular sieve screening of 45 μ m, 40 μ m successively, and the particle diameter that obtains zinc stearate is 40-45 μ m, and calcium carbonate is selected 2500 mesh calcium carbonates for use. The chitosan raw material of this embodiment selects a chitosan raw material with a degree of deacetylation of 95% and a molecular weight of 1000 kDa.

Embodiment 3

[0057] This example is basically the same as Example 1, with slight differences in the distribution ratio of each component and the condition selection of the preparation process. A kind of antibacterial packaging film of the present embodiment is prepared by mixing the components of the following parts by mass:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com