Light ultrahigh-speed stacking machine

An ultra-high-speed, stacker technology, which is applied in object stacking, transportation and packaging, storage devices, etc., can solve the problems of slow stacker speed, large space occupation, and high stacker speed, and achieve 100% positioning Accurate, reduce the bottom space occupation, optimize the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

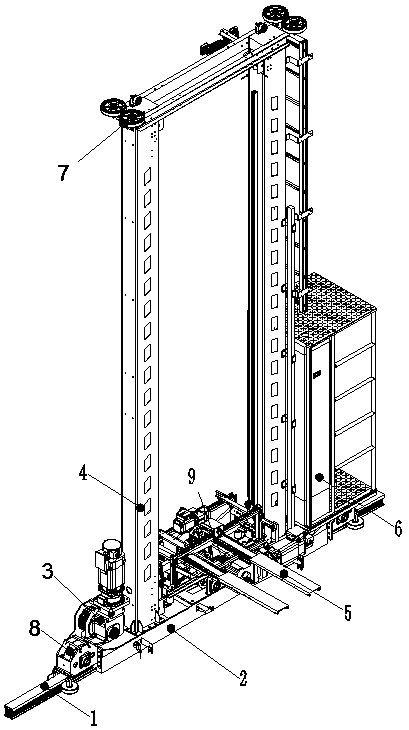

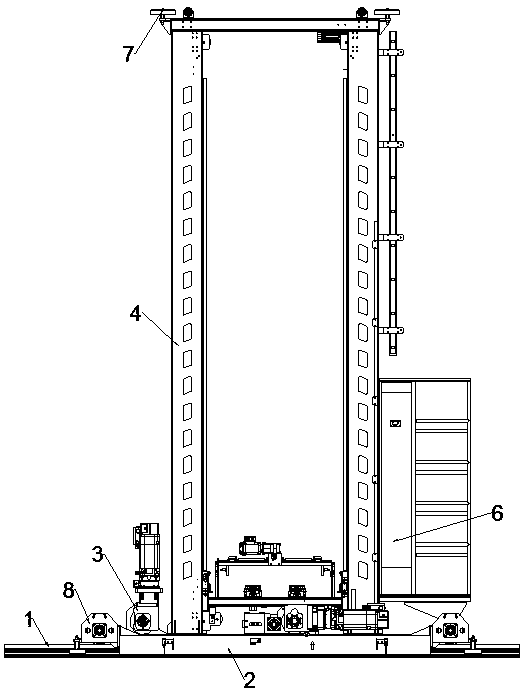

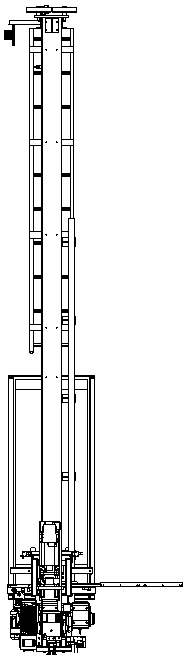

[0020] A light ultra-high-speed stacker, including two bottom beams 2, characterized in that the two bottom beams 2 are respectively arranged on both sides of the middle part of an aluminum alloy ground rail 1.

[0021] The top of the aluminum alloy ground rail 1 is provided with a running surface 1.1, and the upper part of the aluminum alloy ground rail 1 is symmetrically provided with two linear guide wheel surfaces 1.2, and the bottom of the linear guide wheel 7 is provided with an anti-overturning guide wheel surface 1.3 obliquely. The lower part of the aluminum alloy ground rail 1 is symmetrically provided with a mounting pressure block surface 1.4, which can be widely applied to the walking ground rail of various mobile vehicles (RGV) and other equipment.

[0022] The upper part of the bottom beam 2 is symmetrically provided with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com