Machine tool

A technology of machine tools and end caps, which is applied in the field of machine tools, can solve the problems of reduced machining accuracy and poor stability, and achieve the effects of small deformation, guaranteed connection stability, and guaranteed coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

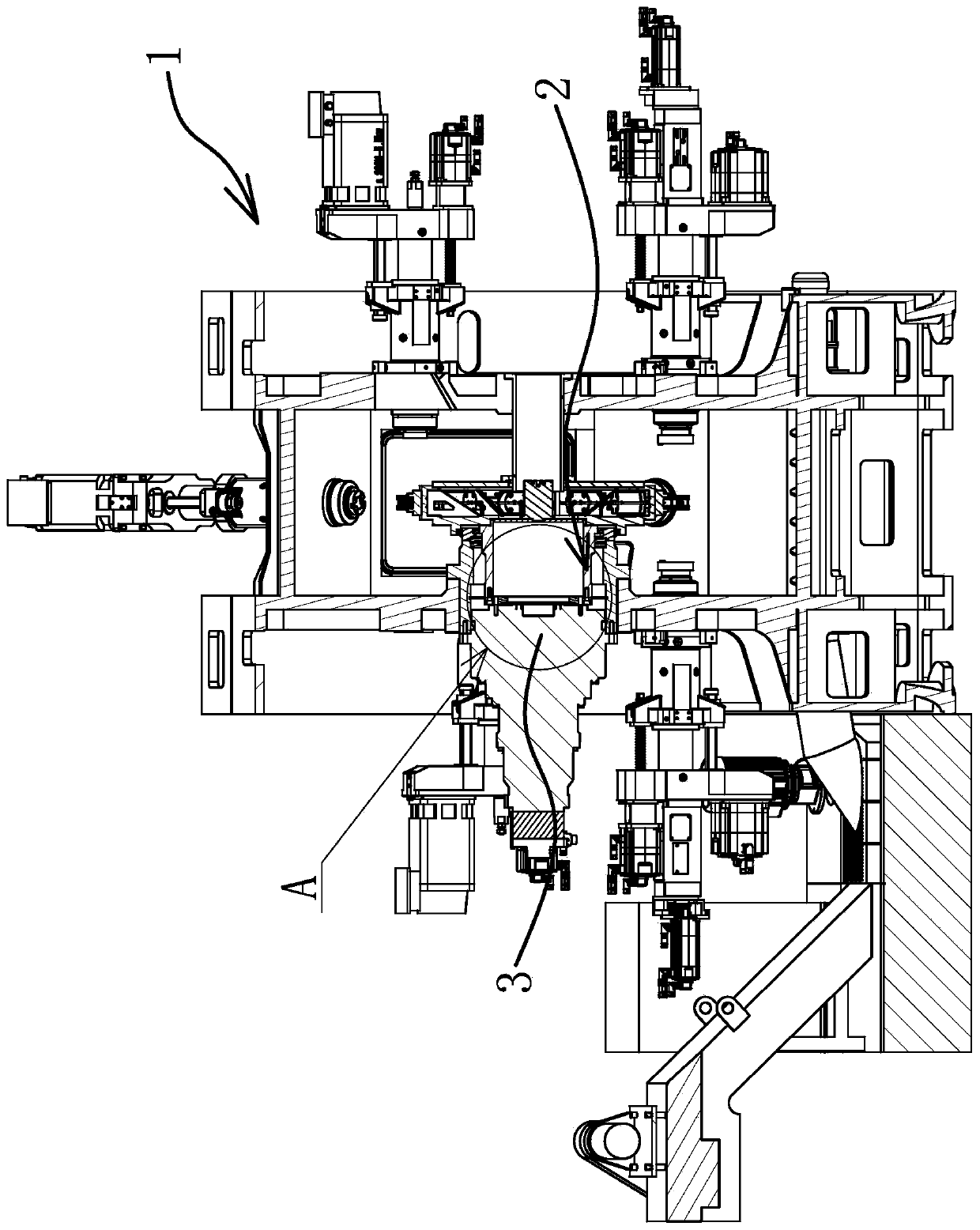

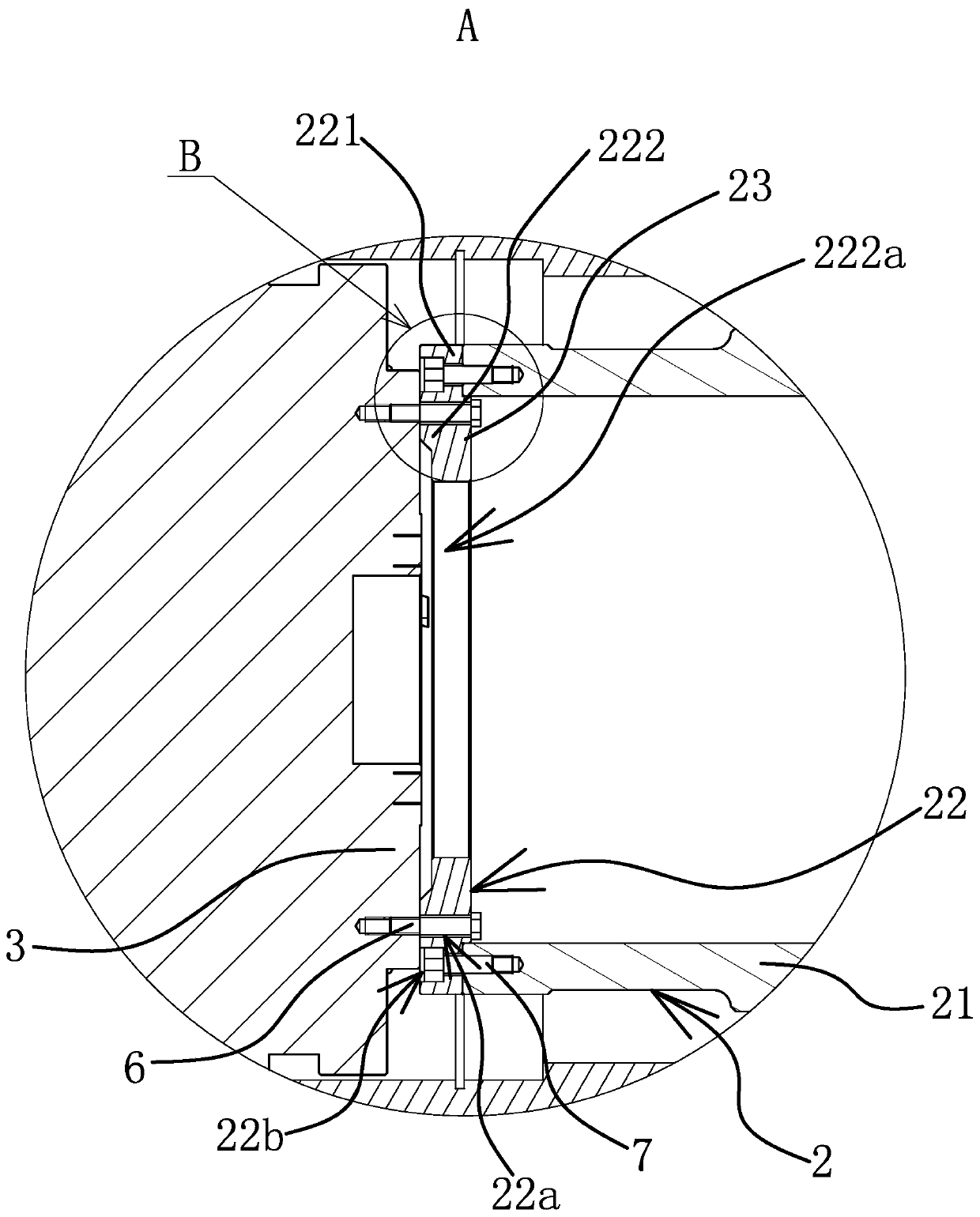

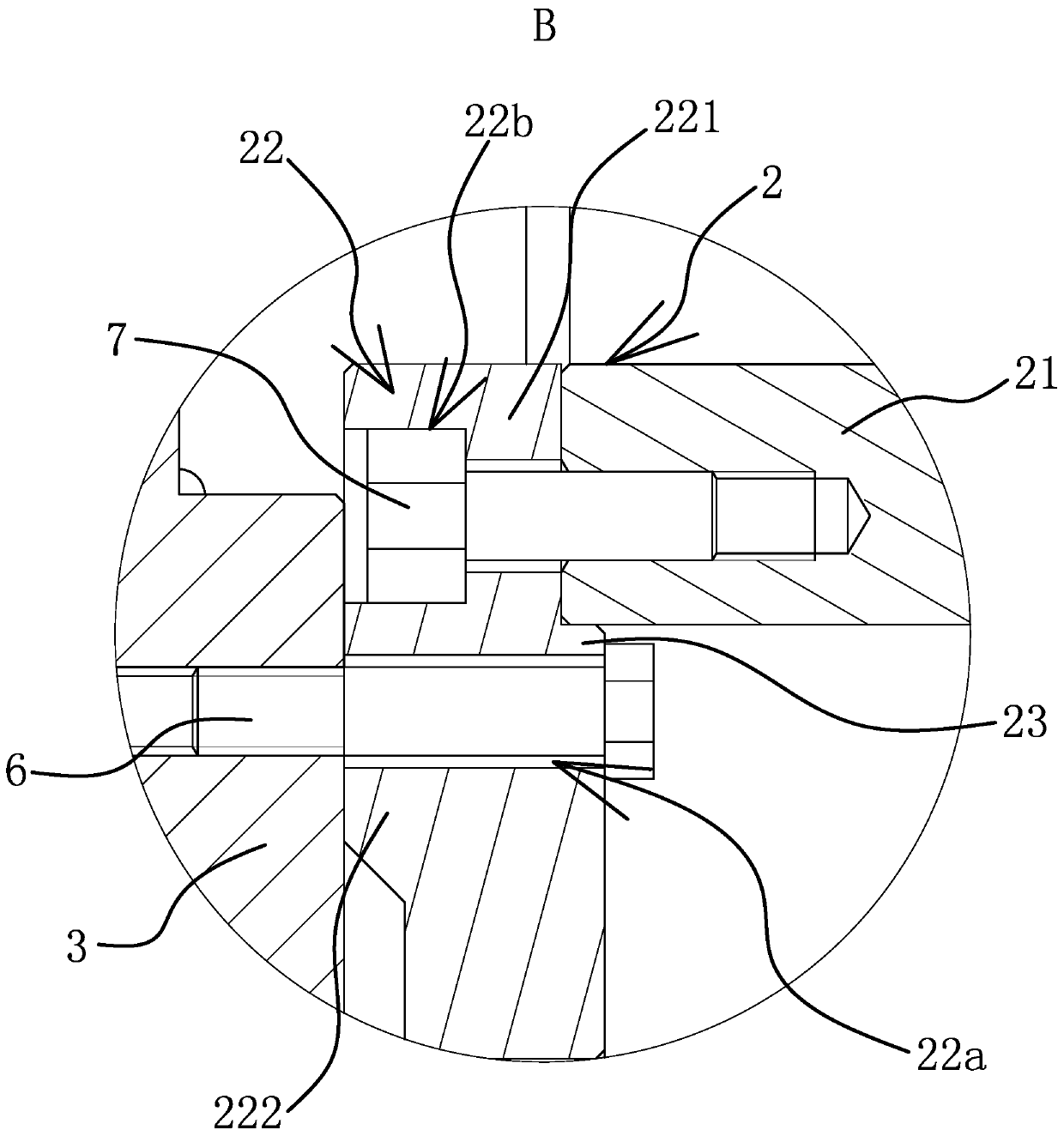

[0035] Such as figure 1 and 2 As shown, the machine tool includes a bed body 1, an auxiliary disc, a main shaft 2 and a turntable 3, and the sub disc, the main shaft 2 and the turntable 3 are all arranged on the bed body 1. The main shaft 2 adopts a split design, including a cylindrical main body 21 and an end cover 22 with a plurality of connection holes 22a, which is easy to manufacture, does not generate redundant waste materials, and is low in cost. The end cover 22 and the turntable 3 are fixedly connected by the fastener 6 passing through the connection hole 22a, and the turntable 3 can drive the main shaft 2 to rotate, and the sub-disk is fixed on the main body 21 of the main shaft 2 and can rotate synchronously wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com