System and method for realizing high-efficiency removal of fine particles in high-temperature gas through electrofiltration coupling

A technology for fine particulate matter and high temperature gas, which is applied in the field of systems for efficient removal of fine particulate matter in high temperature gas by coupling with electric filtration, which can solve the problems of limited temperature application range and achieve the effect of low power consumption and low gas consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be further specifically described below through examples, and these examples are done to illustrate the present invention, not to limit the present invention. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of this application.

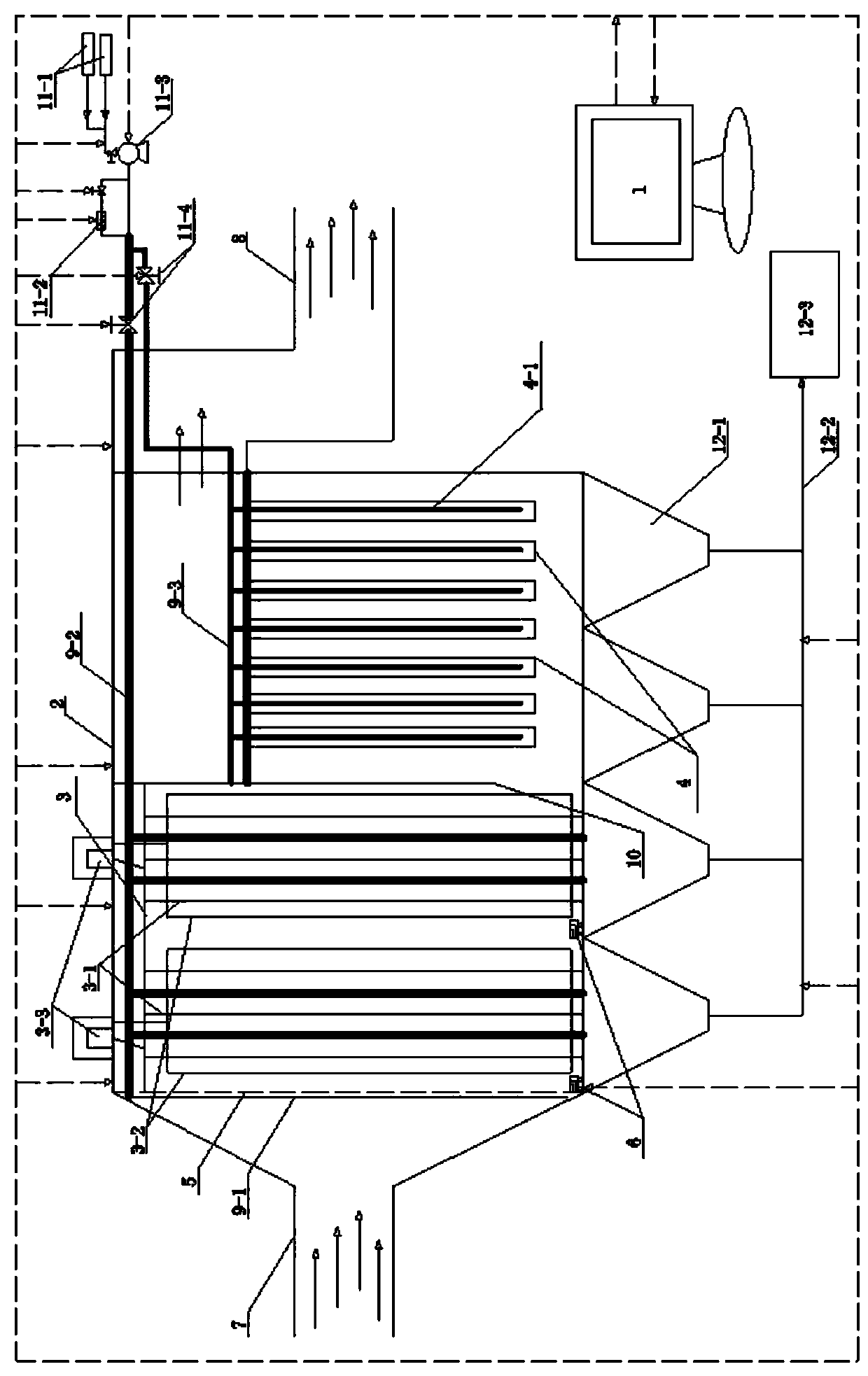

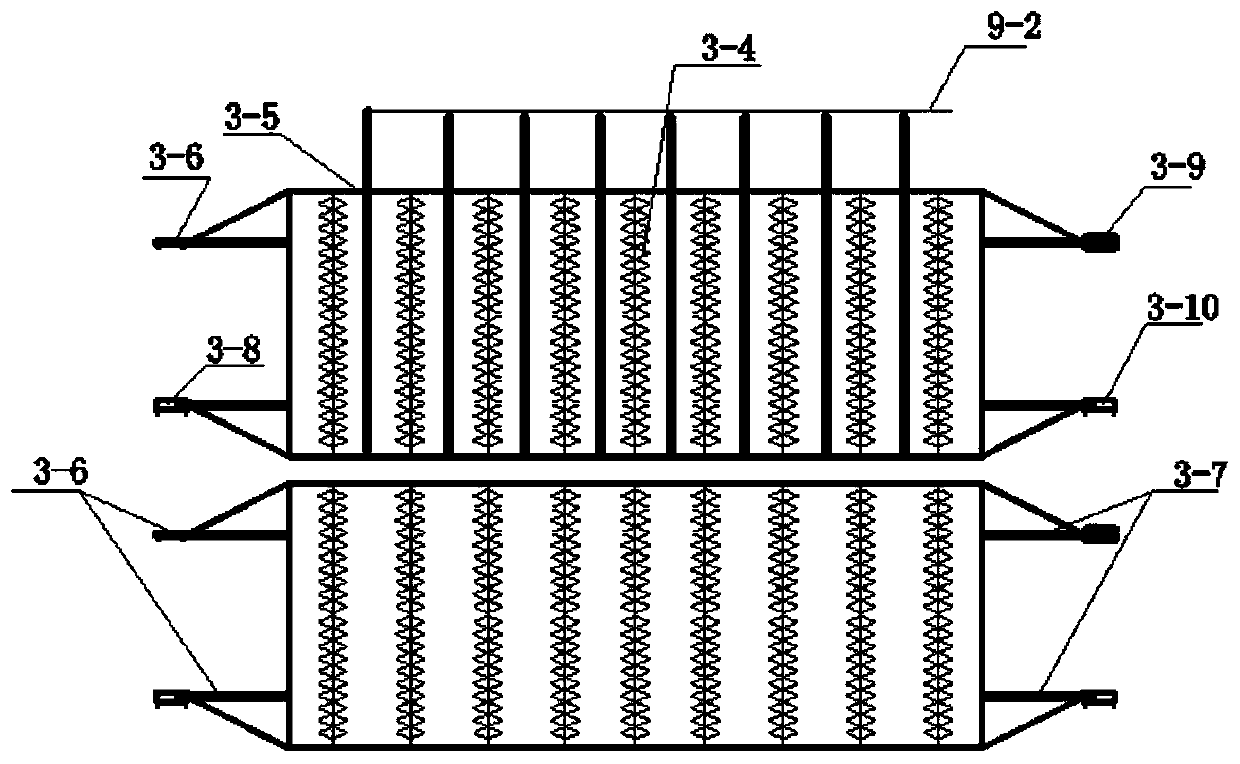

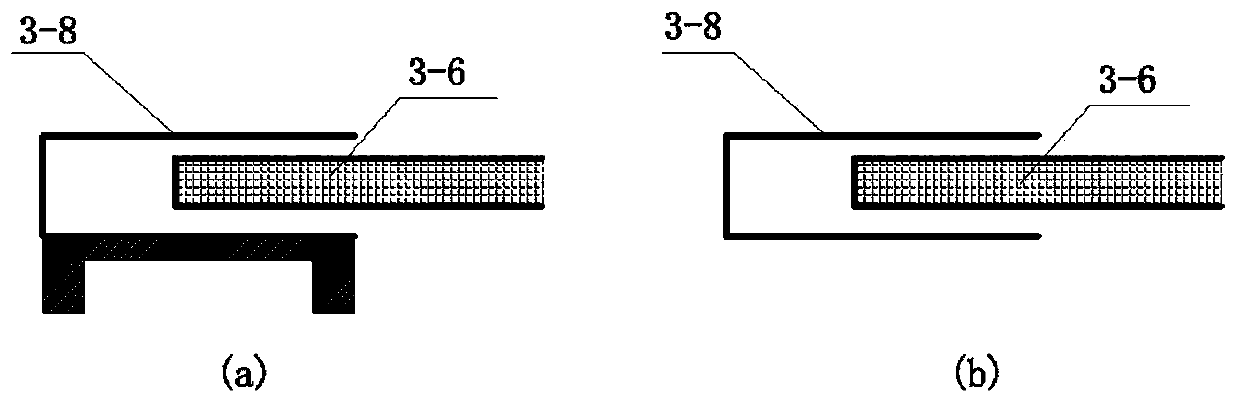

[0051] refer to Figure 1~6 , a system for efficiently removing fine particles in high-temperature gas through electric filtration coupling, the system includes an intelligent control device 1, a filter body 2, a discharge dust removal device 3, a filter dust removal device 4, a rectification device 5, and a tubular dust removal device device, rapping dust removal device 6, hot air device and ash conveying device, the discharge dust removal device 3, filter dust removal device 4, rectification device 5, pipe type dust removal device, and rapping dust removal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com