Slime sorting machine for collecting metal blocks

A metal block and sorting machine technology, which is applied in filtration separation, solid separation, magnetic separation, etc., can solve the problems that impurities are difficult to quickly clean up, and can not fully screen metal blocks, and achieve the effect of improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

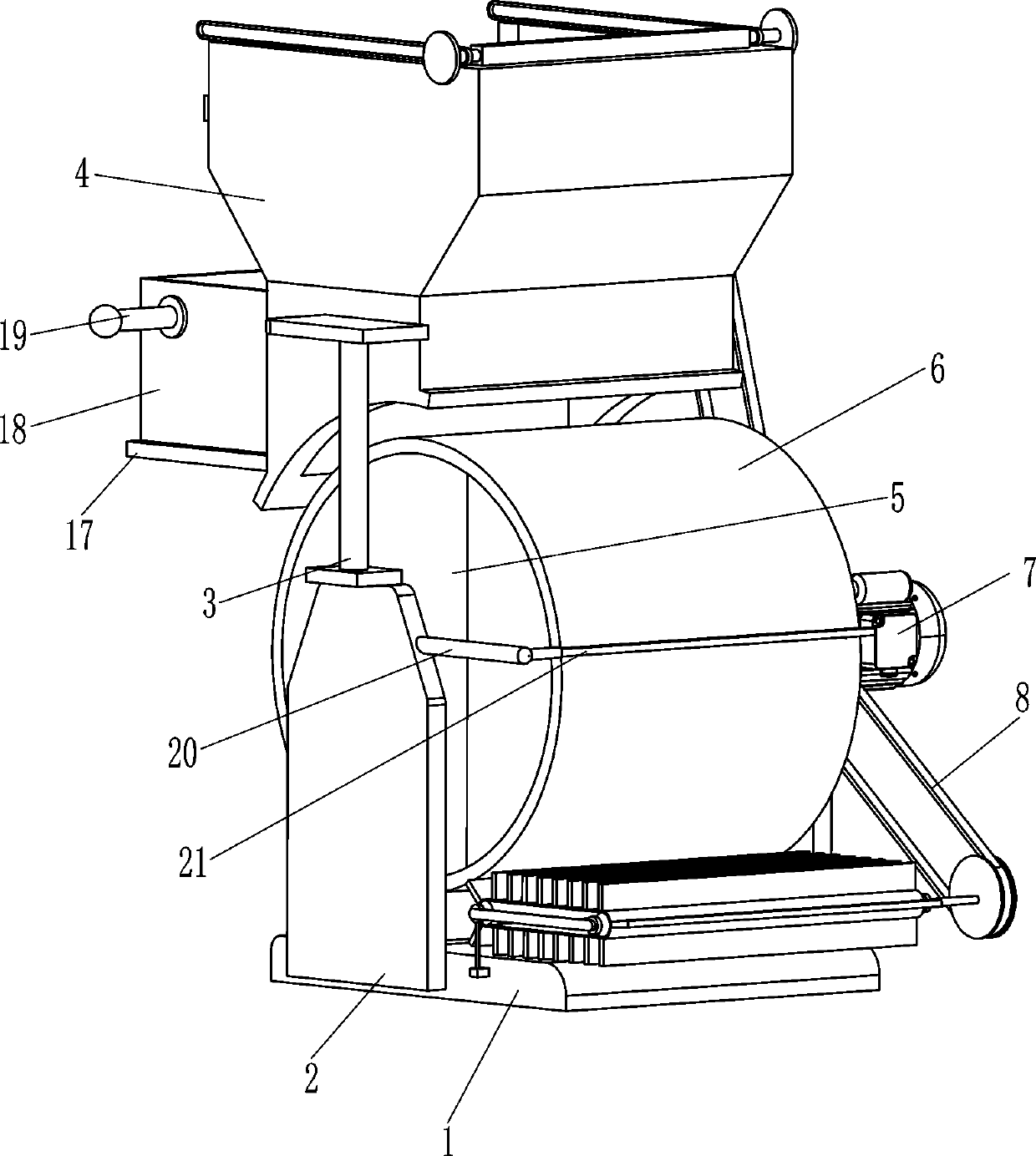

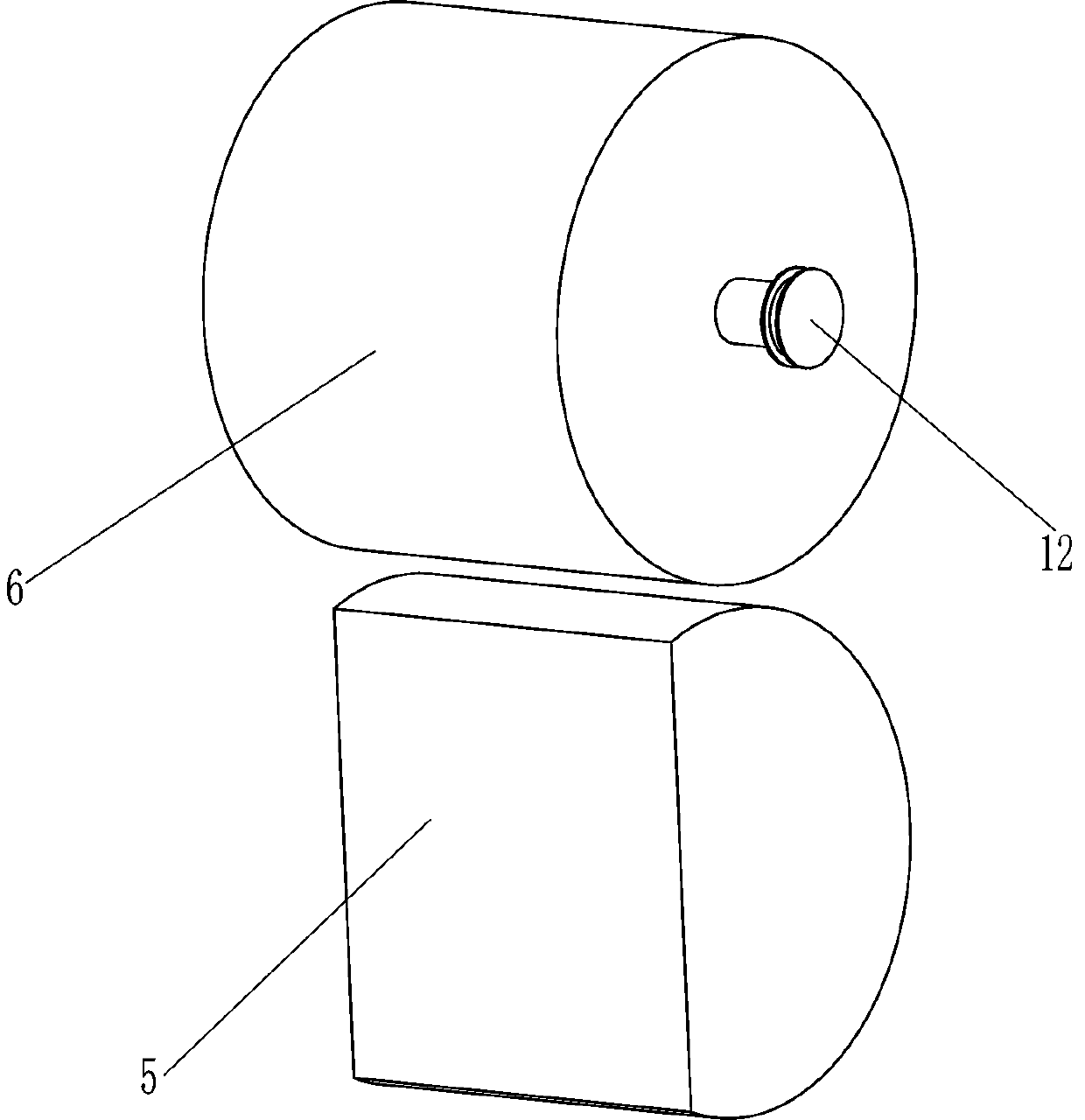

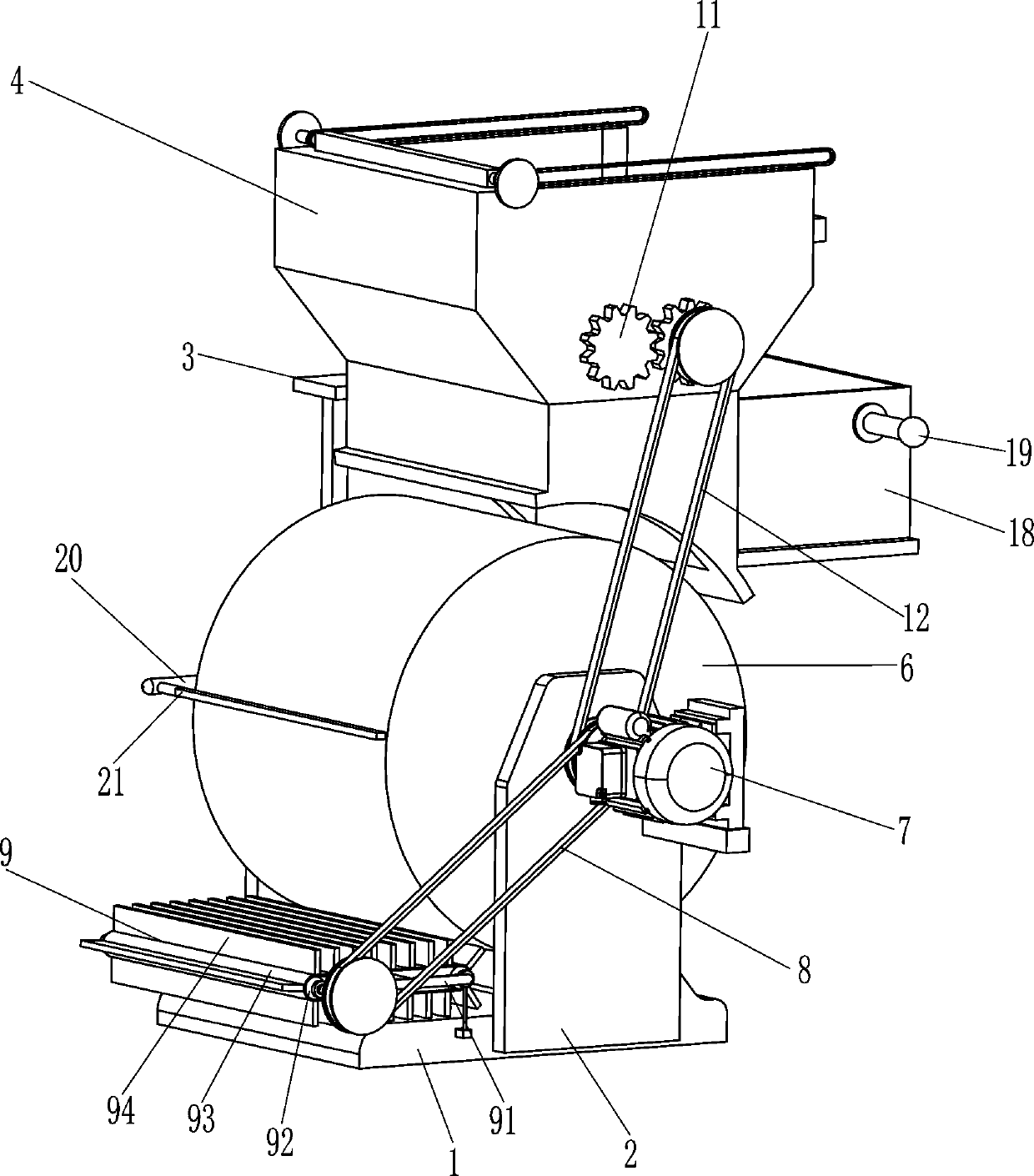

[0022] A slime separator for metal lump collection, such as Figure 1-4 As shown, it includes a bottom plate 1, a mounting plate 2, a mounting column 3, a filter frame 4, a magnetic column 5, a circular drum 6, a driving motor 7, a first transmission assembly 8, a pushing device 9, a squeeze roller 10, a driving Gear 11, second transmission assembly 12 and filter screen frame 13, base plate 1 front and rear sides are all provided with installation plate 2, front side installation plate 2 top is provided with installation column 3, is provided with filter frame 4 on installation column 3, front side The rear side of the mounting plate 2 is provided with a magnetic column 5, the rear mounting plate 2 is rotatably connected with a circular drum 6, the magnetic column 5 is attached to the inner wall of the circular drum 6, and the rear mounting plate 2 is provided with a drive motor 7 , the output shaft of the driving motor 7 is connected with the first transmission assembly 8, th...

Embodiment 2

[0026] On the basis of Example 1, such as image 3 As shown, guide rail 14, push handle 15, push plate 16, sliding plate 17, material receiving frame 18 and handle 19 are also included. Handle 15, push plate 16 is provided at the inner end of push handle 15 on both sides, the bottom of push plate 16 is in contact with the top of filter screen frame 13, a sliding plate 17 is provided on one side of filter frame 4, and the top of sliding plate 17 is slidingly provided with a receiving box 18. Both sides of the receiving frame 18 are provided with handles 19.

[0027] When the equipment is running, if a large amount of impurities are filtered on the top of the filter screen frame 13 and the mud continues to fall down, the worker can drive the push plate 16 to move to the left through the push handle 15, thereby pushing the impurities on the top of the filter screen frame 13. into the material receiving frame 18, while the push plate 16 can rotate freely to ensure that the push p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com