Conductive microneedle paster for wound repairing and preparation method of conductive microneedle paster

A technology of wound repair and microneedle sticking, applied in the direction of electrotherapy, electrodes, wound clips, etc., can solve the problems that the treatment effect needs to be improved, and achieve the effect of promoting wound repair, regulating cell proliferation and differentiation, and preventing re-cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

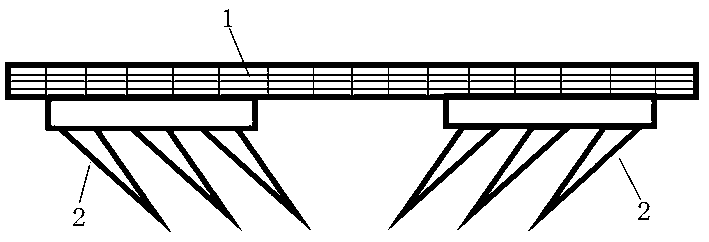

[0029] The invention provides a preparation method for a conductive microneedle patch for wound repair, comprising the following steps:

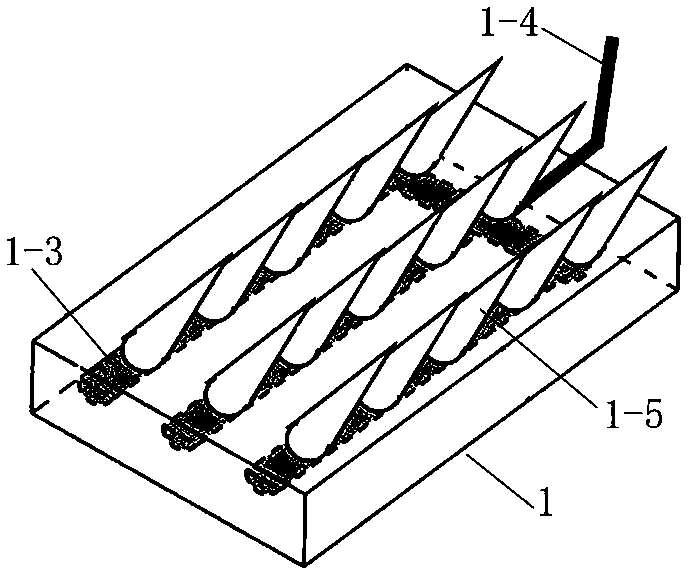

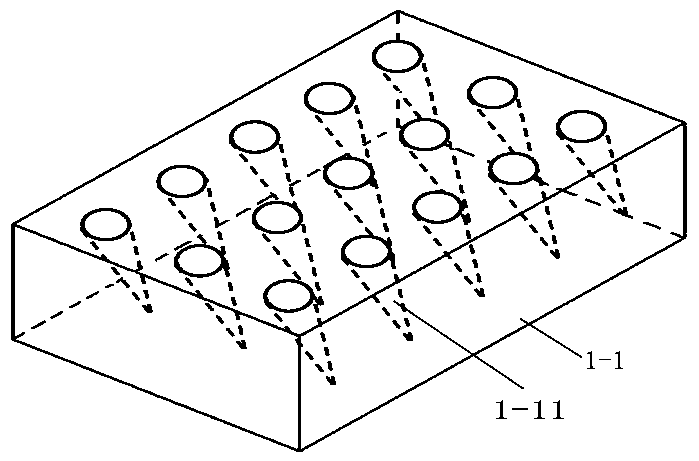

[0030] 1) Preparation of conductive microneedle unit 1: Fully fill the microneedle raw material solution into the lower template 1-1 with inclined needle-shaped holes 1-11 by vacuum or centrifugation, and the cover has "E"-shaped protrusions 1- The upper template 1-2 of 21, after the microneedle raw material solution is solidified, remove the upper template 1-2, press the "E" shaped guide rail 1-3 on the surface of the microneedle, and pour the conductive solution into the "E" shaped guide rail 1-3 On the top, one end of the wire 1-4 is inserted into the conductive solution, and then the microneedle raw material solution is perfused, and after the microneedle raw material solution is solidified, it is peeled off from the lower template 1-1 to obtain a conductive microneedle unit;

[0031] 2) Preparation of conductive microneedle patches: Sel...

Embodiment 1

[0043] A conductive microneedle patch using liquid metal as a conductive solution, prepared according to the following method:

[0044] (1) Configure microneedle raw material solution and conductive solution

[0045] Microneedle raw material solution: Prepare a mixed solution containing polyethylene glycol diacrylate with a mass fraction of 50% and polyethylene glycol methyl methacrylate with a mass fraction of 20% as the microneedle raw material solution, and place it in the dark ; Add 1% 2-hydroxyl-2-methylpropiophenone as the microneedle raw material solution to form a microneedle raw material solution to be cured, and the microneedle raw material solution to be cured is polymerized under ultraviolet light to make the microneedles Solidification of the raw material solution;

[0046] Conductive solution: choose liquid metal as the conductive solution and place it in the syringe.

[0047] (2) Preparation of conductive microneedle unit 1 with needle tip 1-5 inclined to the ...

Embodiment 2

[0054] A conductive microneedle patch using a multi-walled carbon nanotube dispersion as a conductive solution, prepared according to the following method:

[0055] (1) Configure microneedle raw material solution and conductive solution

[0056] Microneedle raw material solution: configure a mixed solution containing 10% hyaluronic acid by mass fraction and 30% methacrylate gelatin as the microneedle raw material solution, and place it in the dark; 2-hydroxyl-2-methylpropiophenone with a volume fraction of 1% is added to the solution to form a microneedle raw material solution to be cured, and the microneedle raw material solution to be cured is polymerized under ultraviolet light to cure the microneedle raw material solution;

[0057] Conductive solution: a multi-walled carbon nanotube dispersion with a mass fraction of 8% was selected as the conductive solution and placed in a syringe.

[0058] (2) Preparation of conductive microneedle unit 1 with needle tip 1-5 inclined to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com