Detachable pulse power capacitor and assembling method

A technology of pulse power and capacitors, which is applied in the field of detachable pulse power capacitors and assembly, can solve the problems of high price of pulse power capacitors, unusable capacitors, and increased customer costs, and achieve simple structure, improved reliability, and increased utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

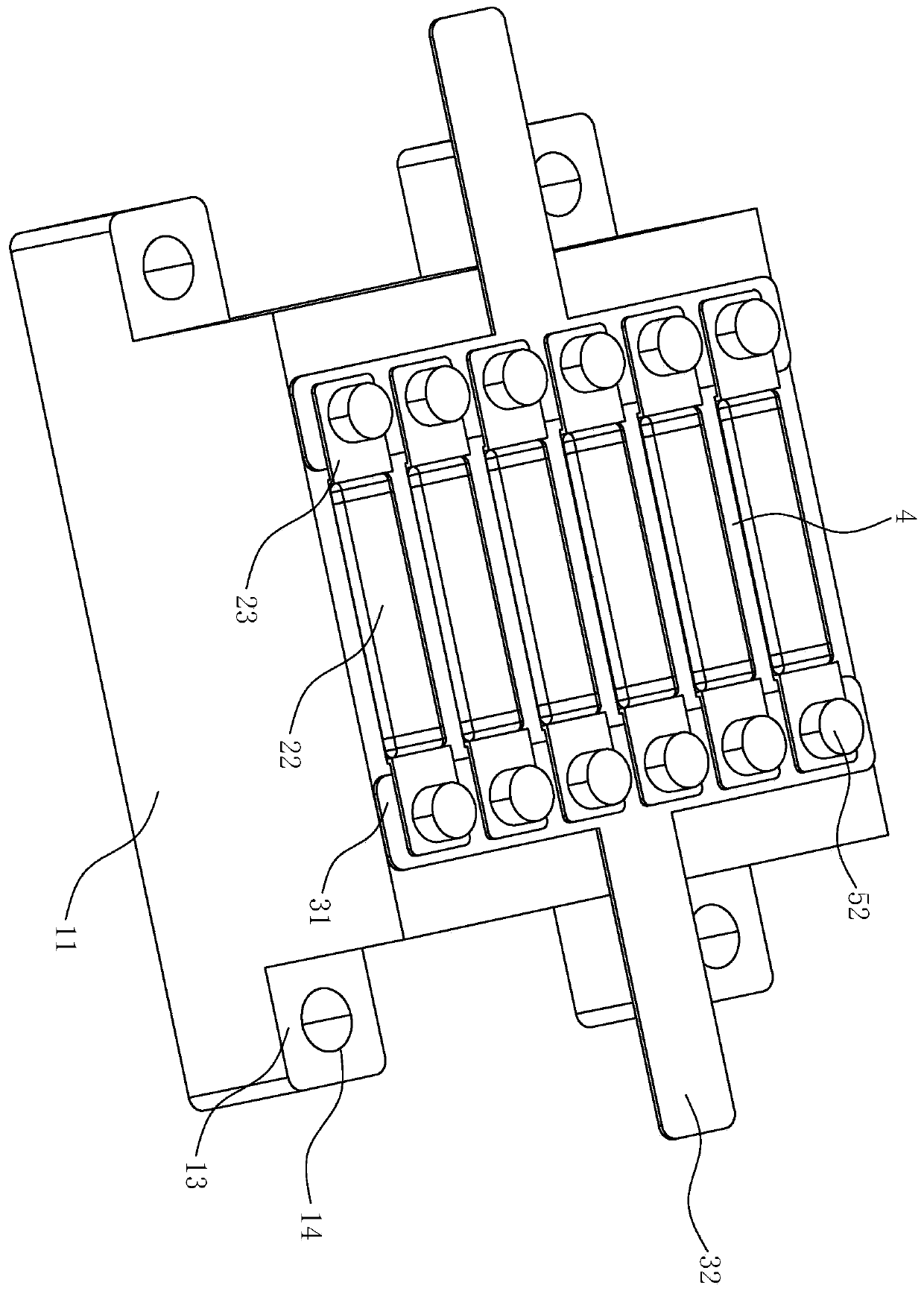

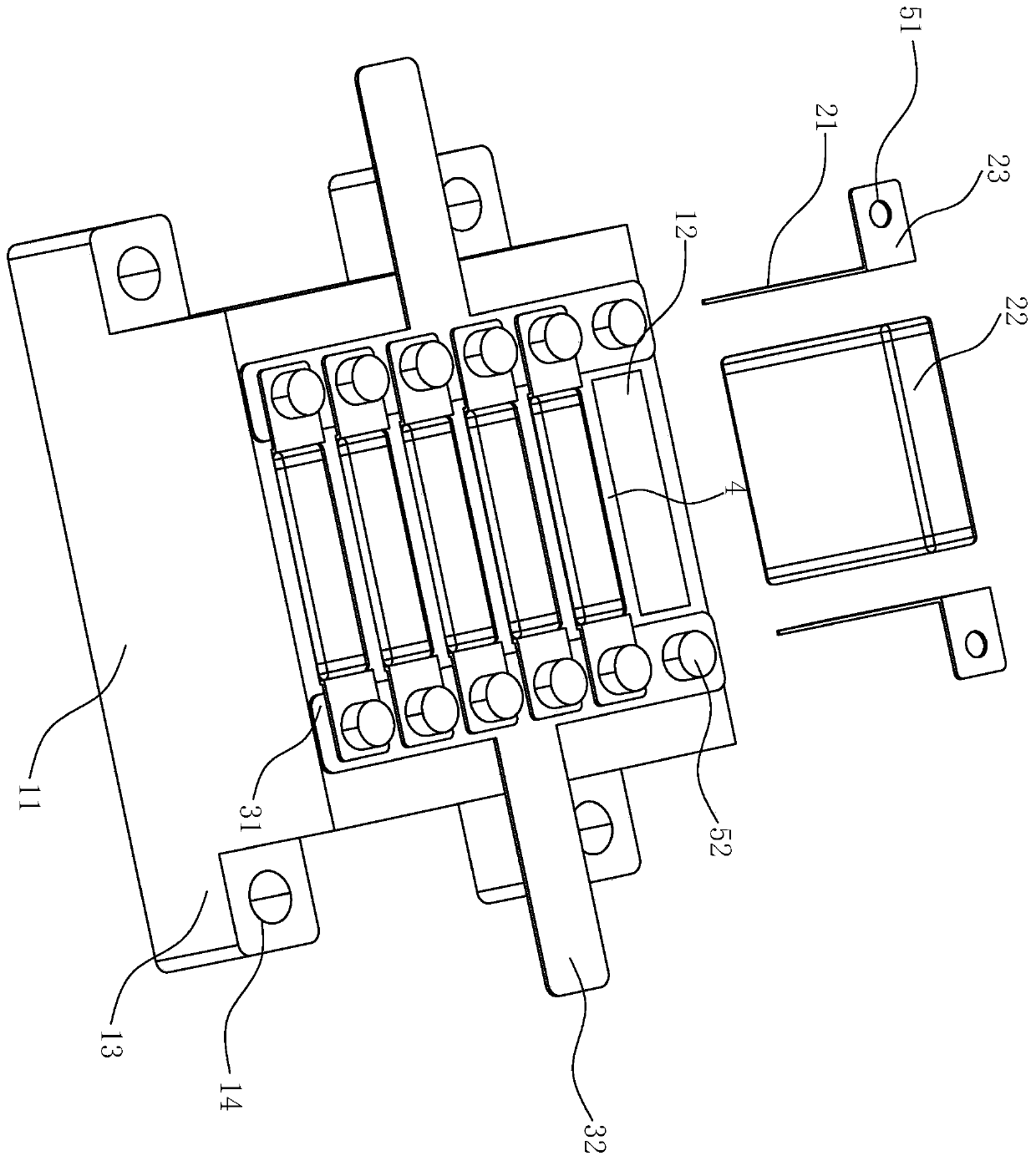

[0023] Such as figure 1 and figure 2 As shown, the detachable pulse power capacitor includes an insulating base, multiple capacitor welding groups, two lead frames and two fixing mechanisms. Multiple capacitor welding groups are detachably arranged on the base at intervals, and two adjacent capacitor welding groups are arranged between There is an isolation part 4, and two lead frames are relatively arranged on both sides of multiple capacitor welding groups. One lead frame is detachably connected to one end of multiple capacitor welding groups, and the other lead frame is detachably connected to the other end of multiple capacitor welding groups. .

[0024] The base includes a base 11 , a plurality of grooves 12 arranged at intervals on the upper surface of the base 11 , and a plurality of fixing seats 13 arranged outside the base 11 . The groove 12 is matched with the capacitor welding group for its insertion. The depth of the groove 12 is slightly smaller than the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com