Gas flux continuous measurement system and measurement method thereof

A measurement system and flux technology, applied in measurement devices, analysis of gas mixtures, structural details of gas analyzers, etc., can solve the problem that the phenomenon of seismic gas escape cannot be captured in real time, the simultaneous measurement of multiple gases cannot be satisfied, and observations cannot be obtained. data and other problems, to avoid the replacement of measurement backgrounds, facilitate seismic fault monitoring, and collect more information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

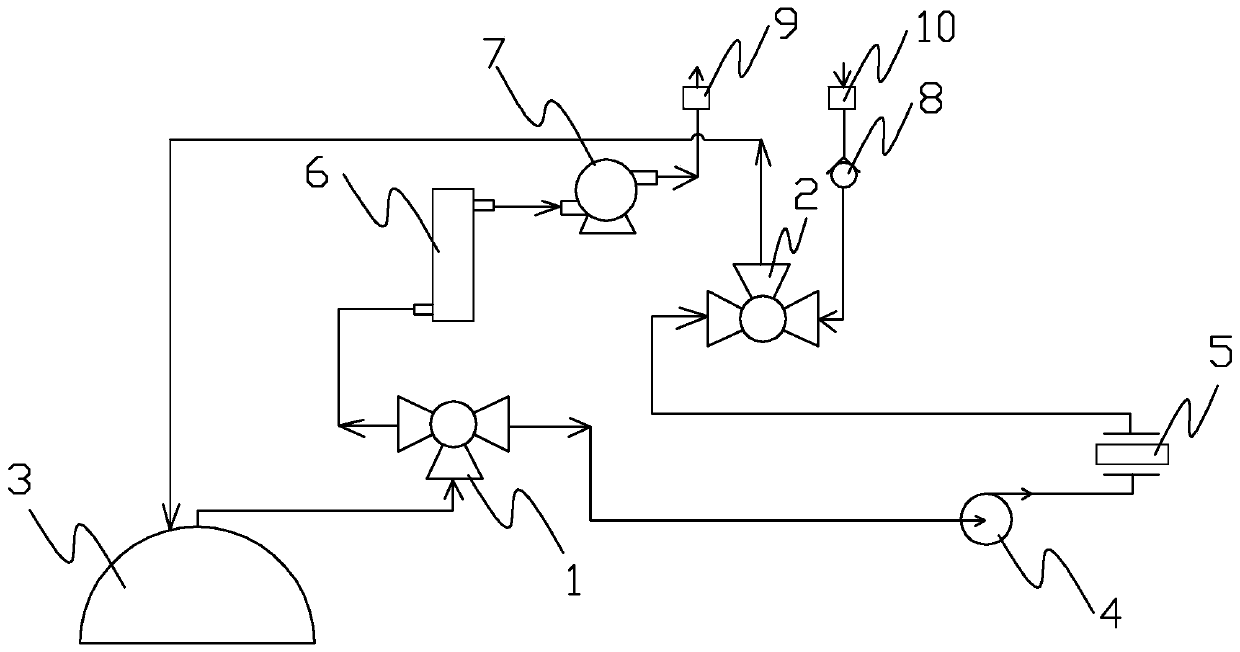

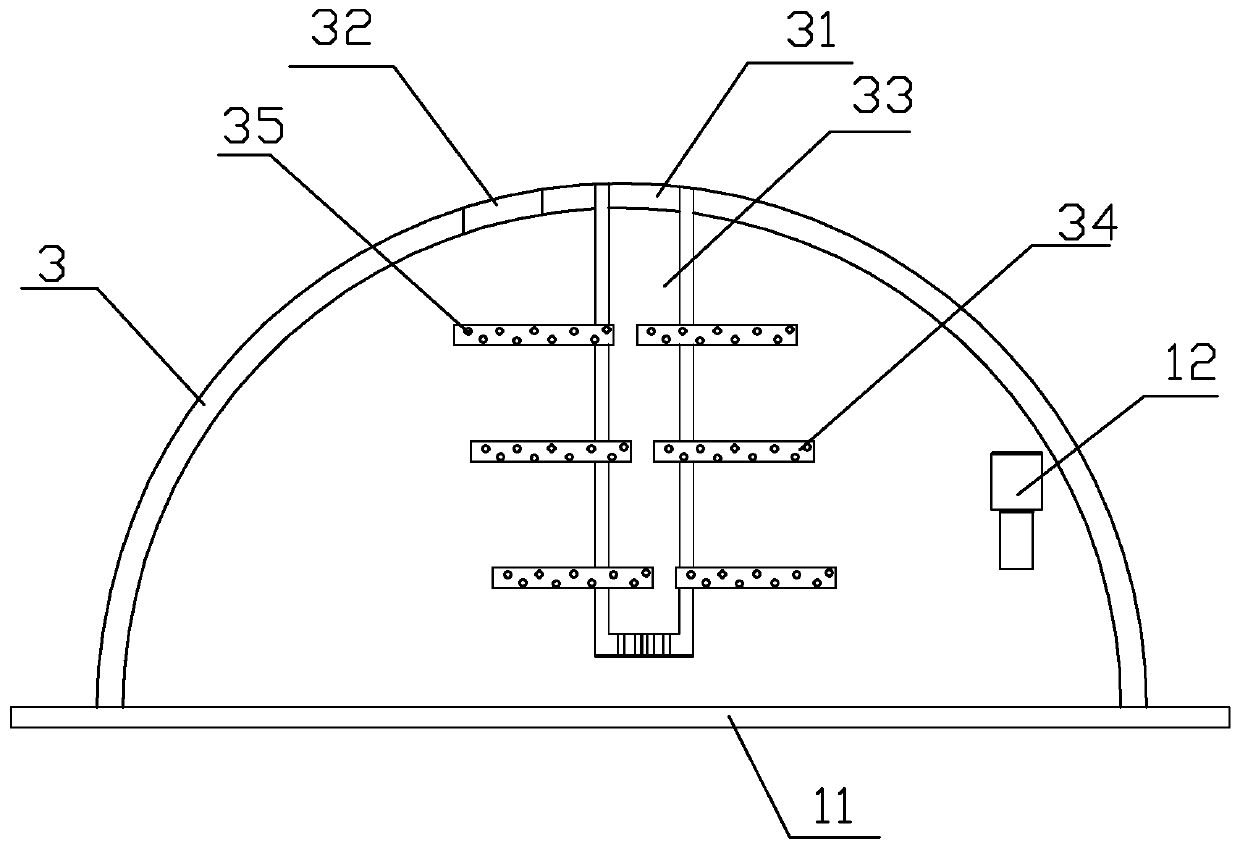

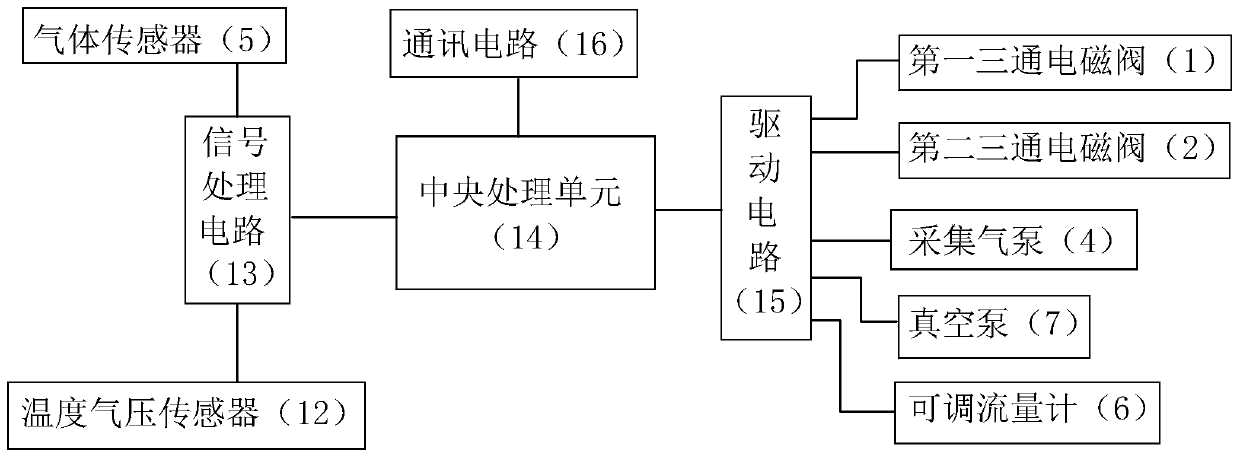

[0027] Embodiment: a kind of gas flux continuous measurement system of this embodiment, such as figure 1 As shown, it includes flux cover 3, first three-way solenoid valve 1, second three-way solenoid valve 2, gas collection pump 4, gas sensor 5, adjustable flow meter 6, vacuum pump 7, one-way valve 8 and main control circuit , the flux cover 3 has an air inlet 31 and an air outlet 32, the gas outlet of the flux cover is connected to the common end of the first three-way solenoid valve, and the first vent end of the first three-way solenoid valve is collected through the gas pump and the gas The air inlet of the sensor is connected, the second ventilation end of the first three-way solenoid valve is connected with the inlet of the adjustable flowmeter, the outlet of the adjustable flowmeter is connected with the inlet of the vacuum pump, and the outlet of the vacuum pump is connected with the system exhaust port 9, The gas outlet of the gas sensor is connected to the first ven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com