Aging evaluation method of single-component RTV coating based on environmental factors

A technology for environmental factors and aging assessment, applied in the analysis of materials, surface tension analysis, material analysis using wave/particle radiation, etc., can solve the problems of less detection content, loss of hydrophobicity, poor mechanical properties, etc., to ensure safety and stability Run and evaluate the effect of many parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

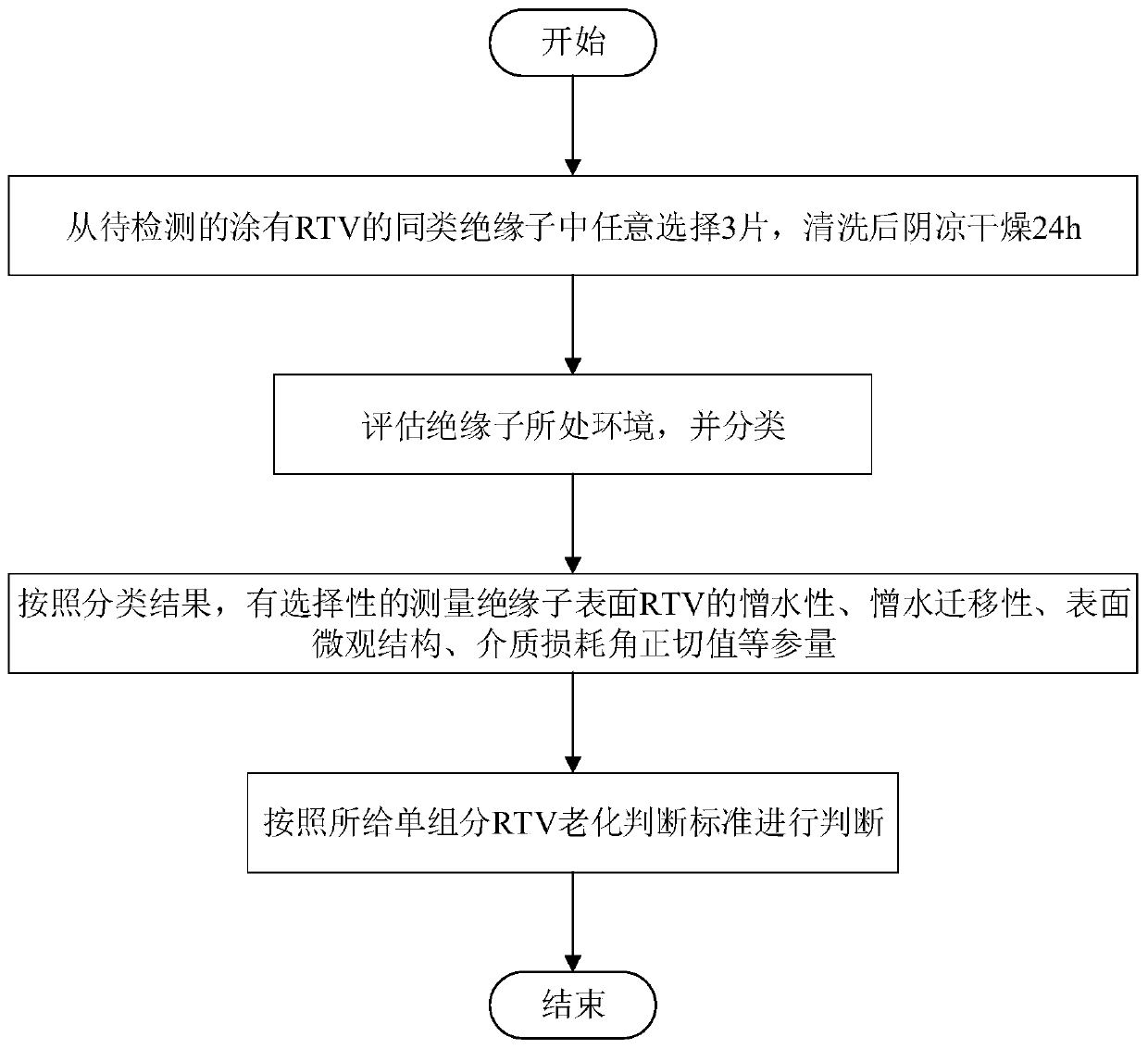

[0078] Such as figure 1 As shown, the aging assessment method of one-component RTV coatings based on environmental factors specifically includes the following steps:

[0079] S100, sampling, taking the single-component RTV paint used on the surface of insulators in Baoji converter station as an example, take three similar insulators to be tested with RTV paint on the surface, clean the surface and dry for 24 hours.

[0080] S200, evaluate the environment of insulators, the ultraviolet radiation index in Baoji area is 5, which belongs to medium ultraviolet intensity, the annual average temperature is 20°C, the annual average relative humidity is 60%, and the annual precipitation is 550 mm. According to Table 1, determine the environment in Baoji area Types belong to a class.

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com