Correction method for absolute error of temperature measuring instrument

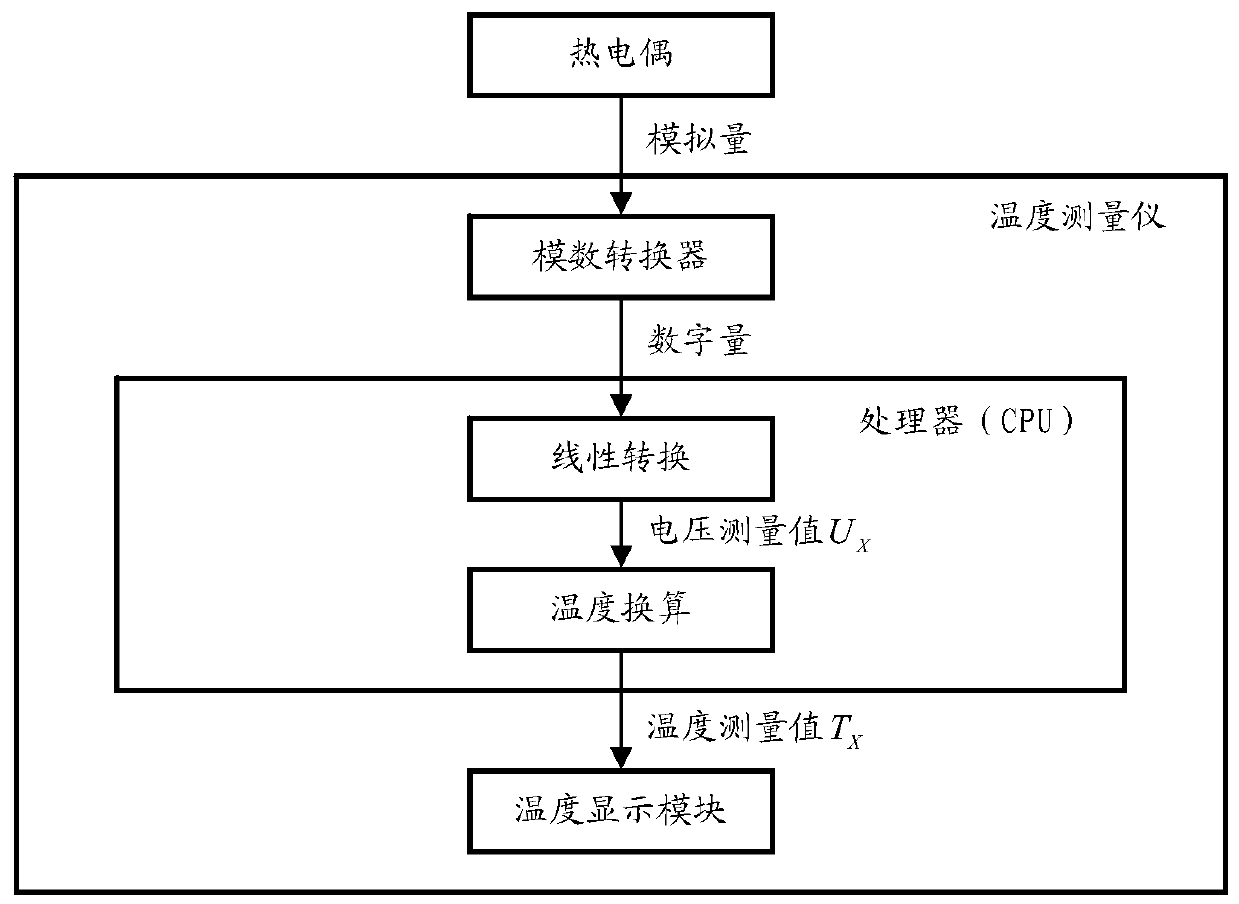

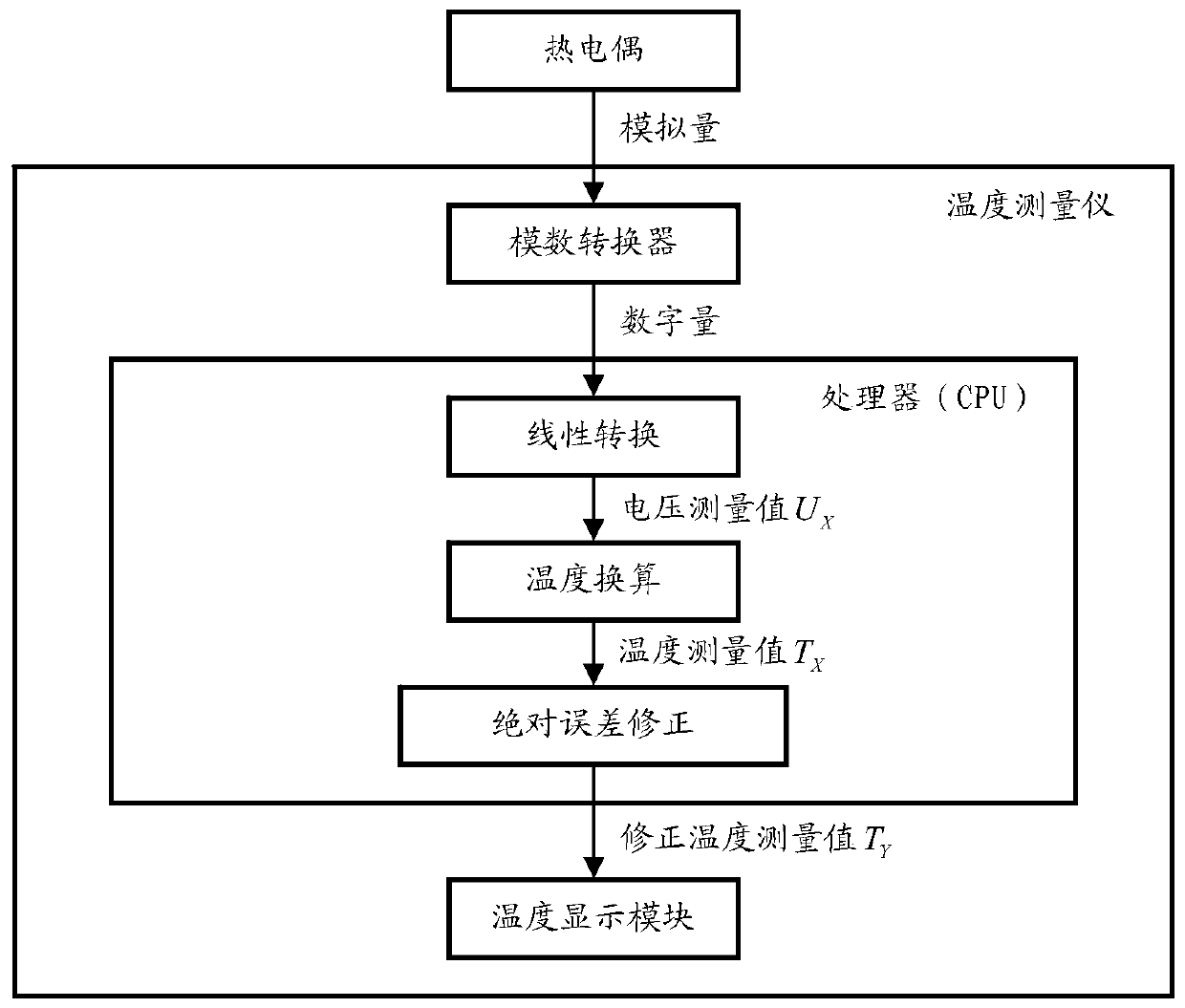

A temperature measuring instrument and absolute error technology, which is applied in the field of correction of the absolute error of the temperature measuring instrument, can solve the problems of reducing the real-time performance of the temperature measurement value, slow data processing speed, and measuring wire error, so as to improve the measurement accuracy and reduce the hardware cost , the effect of meeting the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The thermocouple type is T-type (and the cold junction compensation temperature is 0°C), the measuring range is -170°C to 390°C, and the accuracy requirement is ±0.5°C.

[0121] In the factory calibration state of the temperature measuring instrument:

[0122] S1. Set the factory calibration parameters.

[0123] Set the type of thermocouple as T, the lower limit of the range range d L =-170 and upper limit d H =390, precision requirement value ε=0.5.

[0124] S2. Collecting and processing experimental point data.

[0125] Connect and adjust the signal generating device, and take 10 experimental points within the entire range range -170°C to 390°C (corresponding to -5.070mV to 20.255mV).

[0126] S2.1, sequentially and simultaneously collect the voltage true value U and voltage measurement value U of each experimental point X , the results are shown in Table 1.

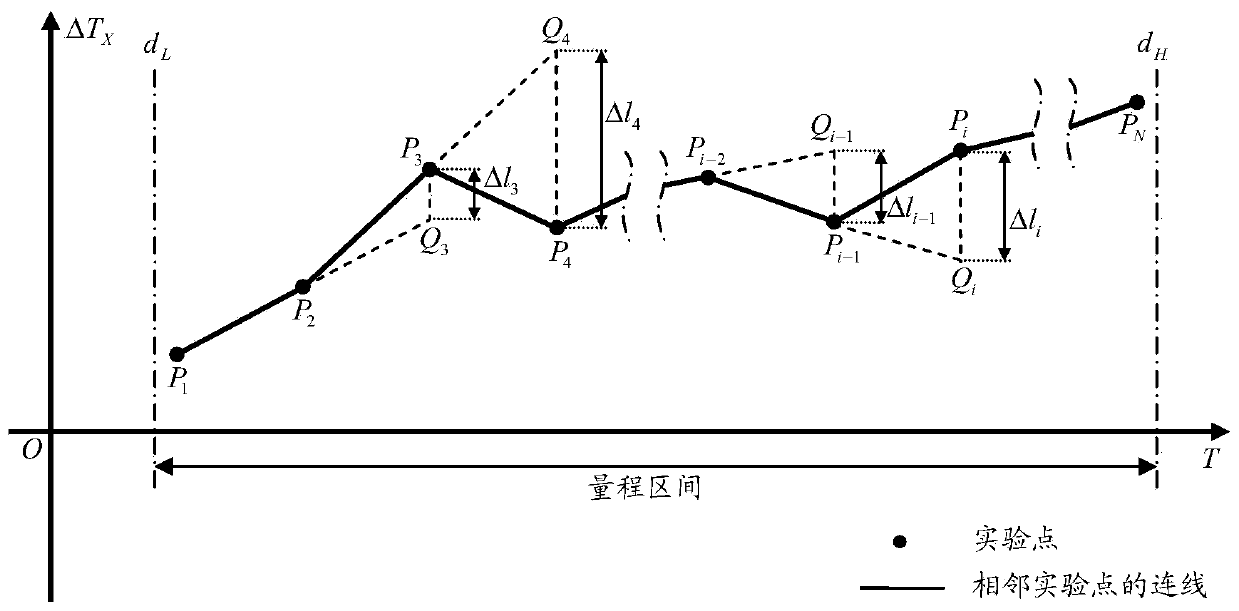

[0127] S2.2. Calculate the true temperature T and measured temperature T of each experimental point X ...

Embodiment 2

[0175] The thermocouple type is T-type (and the cold junction compensation temperature is 0°C), the measuring range ranges from -170°C to 390°C, and the accuracy requirement is ±0.1°C.

[0176] In the factory calibration state of the temperature measuring instrument:

[0177] S1, try to reselect the threshold constant ΔL=0.4783 (i.e. Δl in Table 2 8 value) to meet the accuracy requirements.

[0178] S2. Calculate the fitting function expression ΔT when ΔL=0.4783 X =F(T).

[0179] (1) Combining ΔL=0.4783 and Δl in Table 2 i The value of Δl can be known 3 ,Δl 4 ,Δl 6 ,Δl 7 ,Δl 8 Satisfy Δl i ≥ΔL. Now by [m1]=3, [m2]=4, [m3]=6, [m4]=7, [m5]=8, get [m1]-1=2, [m2]-1=3, [m3]-1=5, [m4]-1=6, [m5]-1=7, so point row P 1 ,P 2 ,P 3 ,P 5 ,P 6 ,P 7 ,P 10 Contains the first and last fit points of all line segments.

[0180] (2) Using the least squares method, from the point P 1 ,P 2 Fit the first piecewise straight line equation, from point P 2 ,P 3 Fit the second piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com