An industrial waste treatment incineration tail gas denitrification device and its use method

A technology for industrial waste and tail gas, which is applied in the direction of combustion methods, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of complicated procedures and increase the cost of flue gas denitrification treatment, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

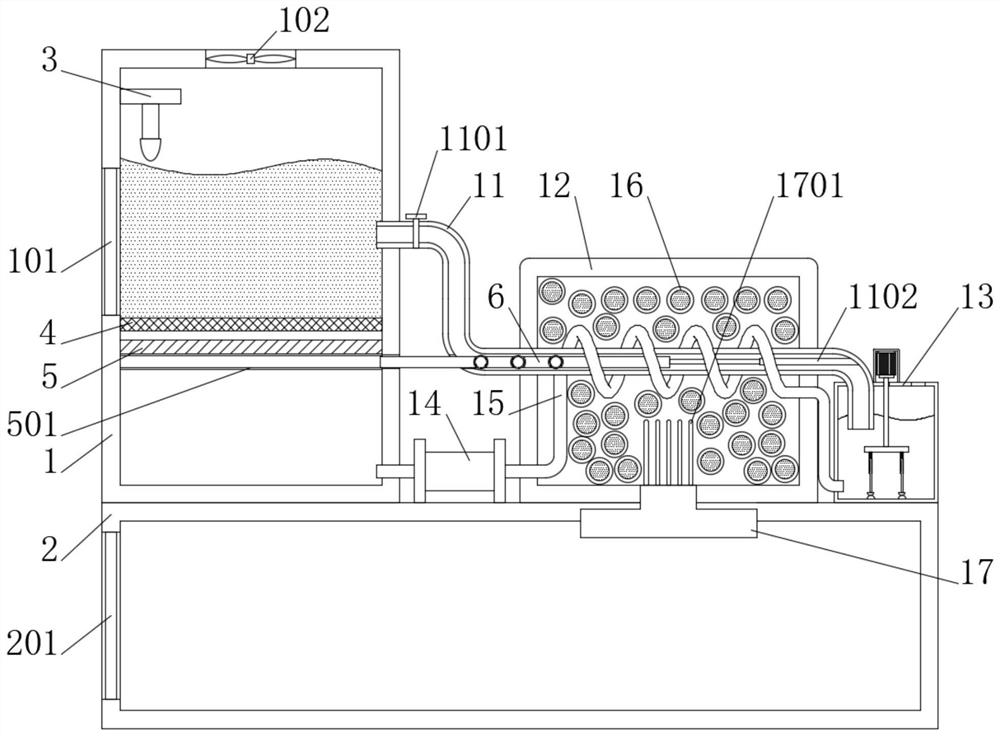

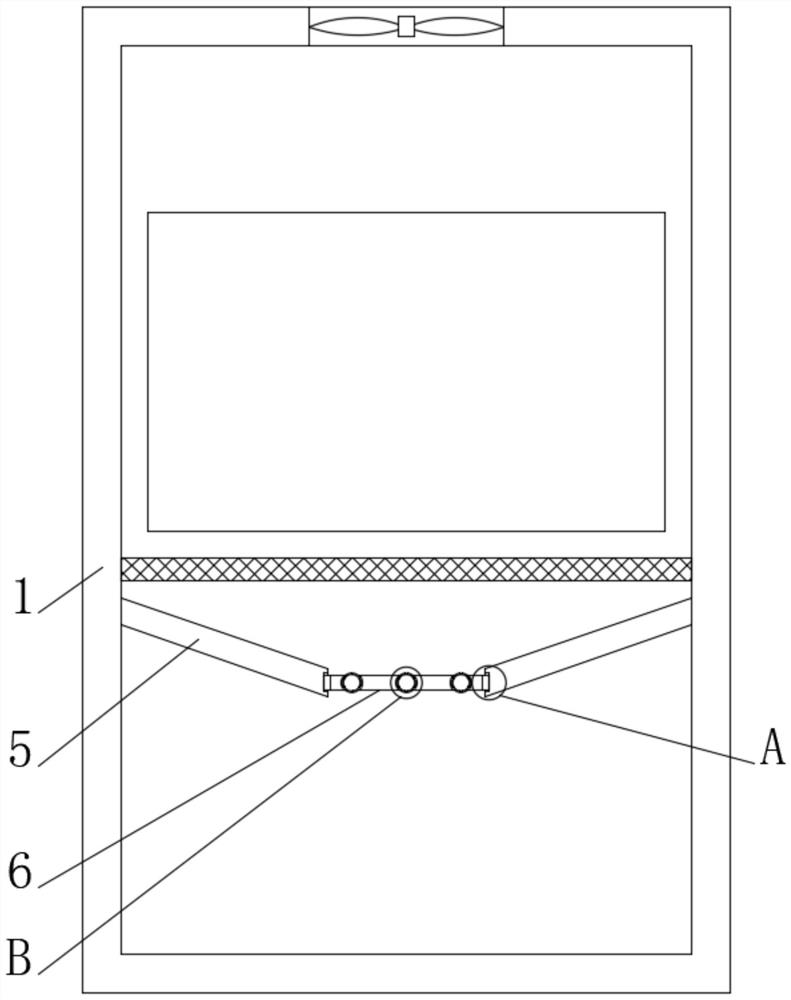

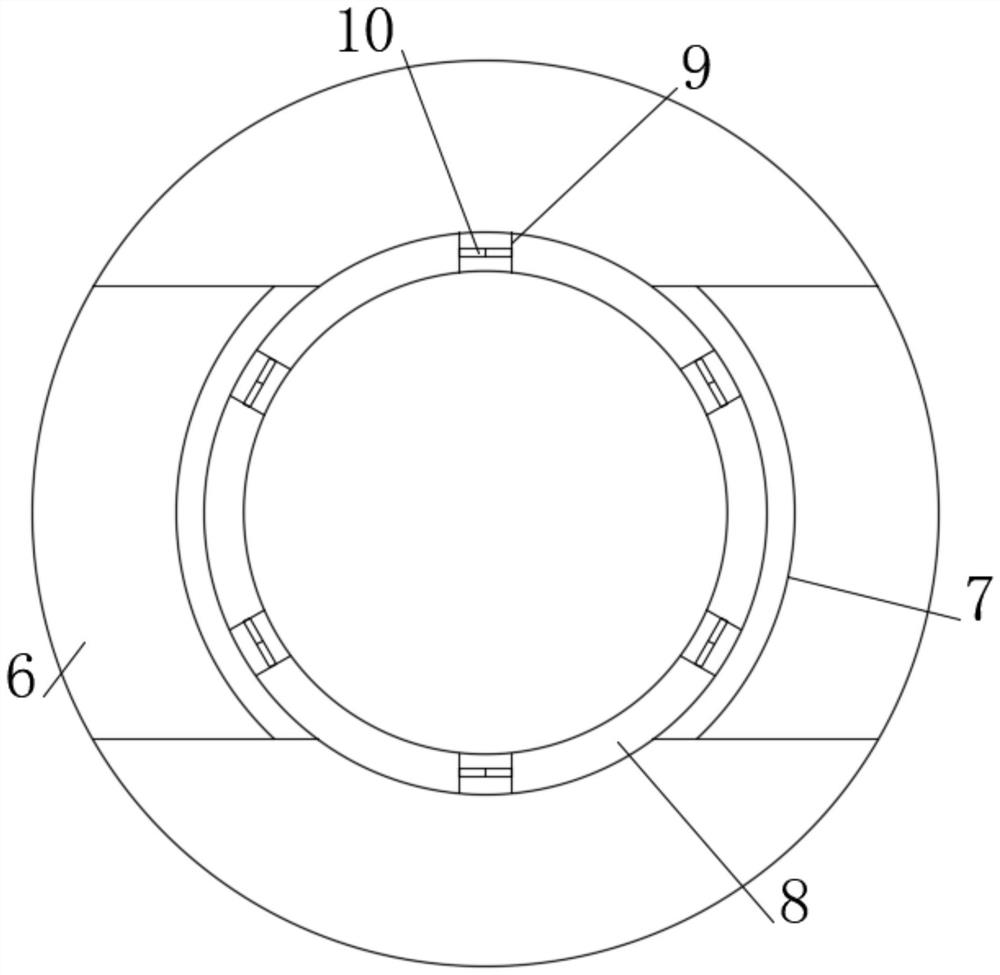

[0036] see Figure 1-2 , an industrial waste treatment incineration tail gas denitrification device and its use method, comprising an incineration box 1 and a main control room 2, the incineration box 1 is located at the upper end of the main control room 2 and is fixedly connected with the main control room 2, and the left inner wall of the incineration box 1 is fixed Connected with an ignition device 3, a metal filter 4 is fixedly connected between the left and right inner walls of the incineration box 1, and the upper side of the metal filter 4 is filled with garbage waste, and a pair of side connecting plates 5 are fixedly connected to the left and right inner walls of the incineration box 1. A horizontal filter plate 6 is arranged between the connecting plates 5, and a plurality of uniformly distributed spherical grooves 7 are dug at the outer end of the horizontal filter plate 6, and rubber balls 8 are arranged in the spherical grooves 7, and the rubber balls 8 are filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com