Prediction method of sand and water production profile in horizontal well and optimal design method of sand control and water control screen

A prediction method and technology for horizontal wells, which can be used in surveying, earth-moving drilling, wellbore/well components, etc., and can solve problems such as insufficient understanding of the microscopic synergistic production mechanism of sand and water, fine sand and gravel spalling in the formation, and wellbore blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

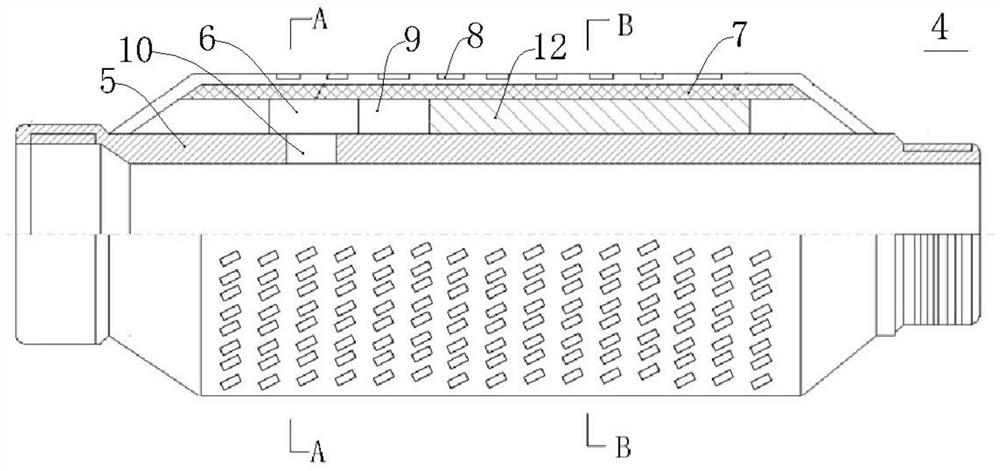

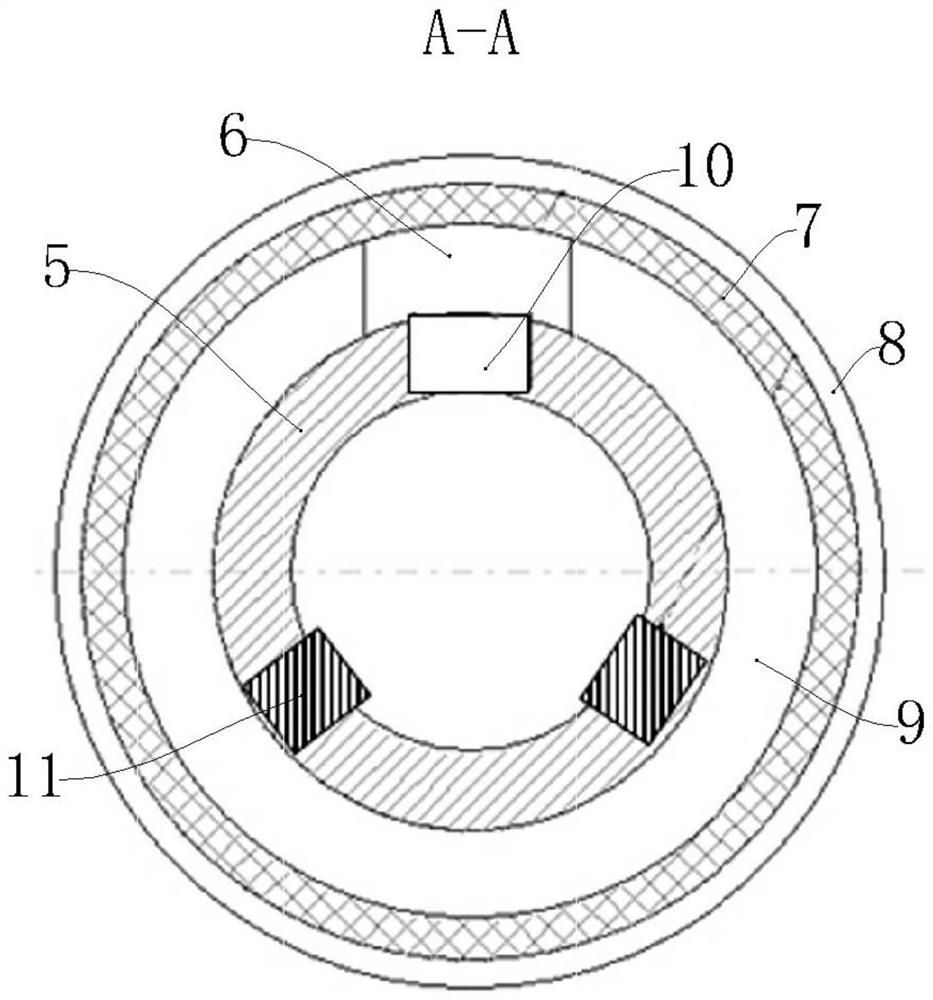

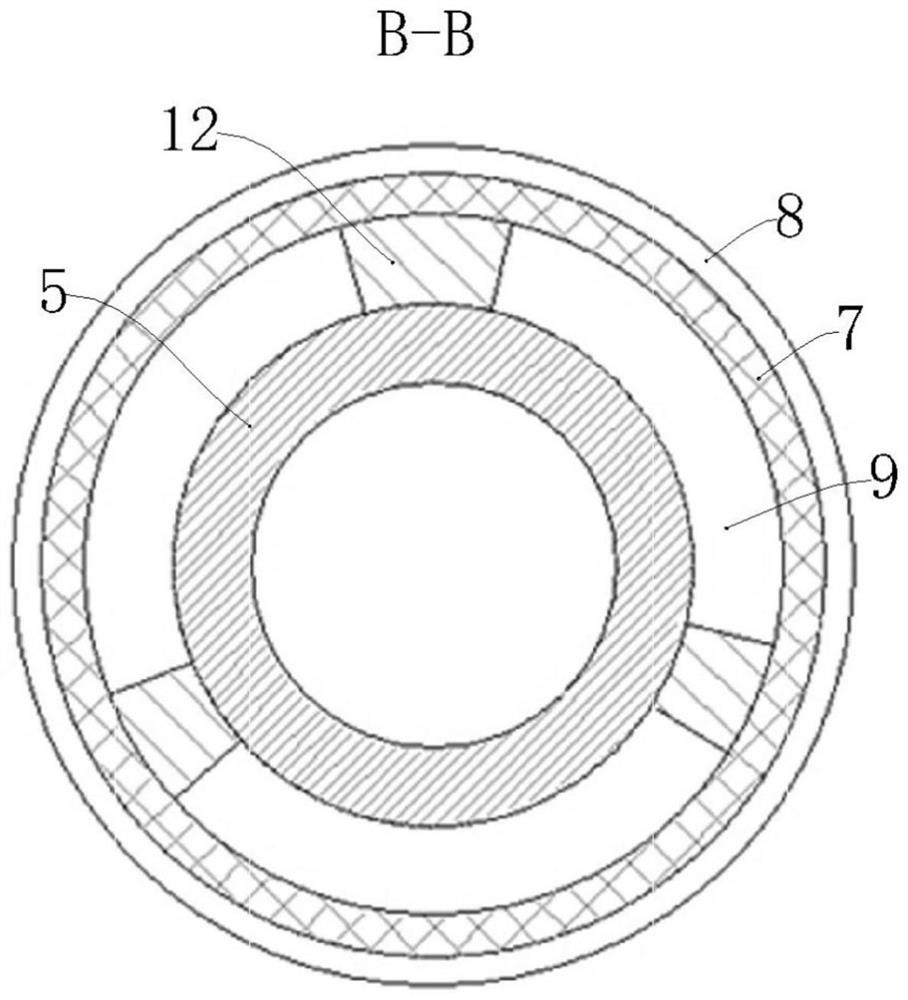

[0092] Example, a case of integrated completion design of sand control and water control for a horizontal well in an oilfield. The oilfield is a loose and easy-to-sand high-yield oil reservoir, and the integrated construction of screens for sand control and water control is used to complete the well. The production interval of a horizontal well in this oilfield is about 110m long. Combined with the actual production practice of this oilfield, some high-yield wells in this oilfield have serious water and sand production.

[0093] First, calculate the co-production intensity coefficient of sand and water in the production interval and draw the change curve along the production interval, which is the profile of sand and water production:

[0094] Step 1: If Figure 18-20 As shown, the resistivity logging data, spontaneous potential logging data, gamma ray logging data, overall acoustic wave time difference logging data and water cut production data of the production interval we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com