Two-opening one-time-drilling drilling tool combination suitable for oil well horizontal well construction and construction method thereof

A construction method and drilling tool assembly technology, which are applied in drilling equipment and methods, wellbore/well components, and automatic drilling control systems, etc. It can improve the sand-carrying property and lubricity, reduce the number of trajectory adjustments, and shorten the construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

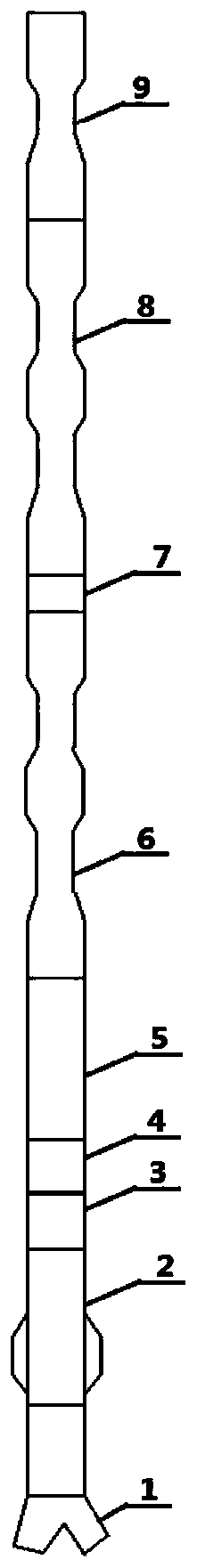

[0027] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a two-run one-trip drilling tool assembly suitable for oil well and horizontal well construction, including a low-end drill bit 1, a screw rod 2, a back pressure valve 3, and a wireless directional joint while drilling 4. Non-magnetic drill collar 5, first weighted drill pipe 6, hydraulic oscillator 7, second weighted drill pipe 8 and drill pipe 9 at the top. Er 3. Wireless directional joint while drilling 4, non-magnetic drill collar 5, first heavy drill pipe 6 connected in turn, hydraulic oscillator 7, second heavy drill pipe 8 and top drill pipe 9 are suitable for horizontal well construction in oil wells Two open trips to drill the BHA.

[0028] In actual use: the low-end drill bit 1 is sequentially connected to the screw rod 2, the back pressure valve 3, the wireless directional joint while drilling 4, the non-magnetic drill collar 5, the first heavy drill pipe 6 is con...

Embodiment 2

[0033] Compared with Embodiment 1, the difference of this embodiment is that: the first heavy drill rod 6, the second heavy drill rod 8 and the drill rod 9 are all heavy drills with a button type of 411X 410 and a diameter of Φ127mm The first heavy drill rod 6 is composed of 9 heavy drill rods with a button type of 411X 410 and a diameter of Φ127mm, and the second heavy drill rod 8 is composed of 30-36 heavy drill rods with a button shape of 411X 410 and a diameter of Φ127mm Rod composition.

[0034] Preferably, the second heavy drill rod 8 is composed of 33 heavy drill rods with a button shape of 411X 410 and a diameter of Φ127mm.

[0035] In actual use: the first heavy drill pipe 6, the second heavy drill pipe 8 and the drill pipe 9 are all heavy drill pipes with a button type of 411X 410 and a diameter of Φ127mm, which are convenient to connect with the hydraulic oscillator 7 and the drill pipe 9. A heavy drill pipe 6 is composed of 9 heavy drill pipes with button type of ...

Embodiment 3

[0039]Compared with Example 1, the difference of this example is that the drill bit 1 is a 6-blade 16mm composite sheet long-gauge double-row special-shaped tooth PDC drill bit, and the button type of the drill bit 1 is a 431PDC drill bit with a diameter of Φ215mm. .9mm.

[0040] In actual use: Drill bit 1 is a 6-blade 16mm composite long-gauge double-row special-shaped tooth PDC drill bit. The buckle type of drill bit 1 is 431PDC drill bit with a diameter of Φ215.9mm. It has strong aggressiveness and good wear resistance. High speed, compared with the conventional 5-blade 19mm composite PDC drill bit, the force on the blade is uniform, the sliding drilling tool surface is more stable, the sliding drilling efficiency is higher, the wear resistance is strong, and the drilling footage is increased, which can ensure fast and safe drilling The completion of the second drilling trip of the horizontal well of the oil well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com