Method for exhausting arch rib air in process of pouring concrete in arch bridge steel pipe

A concrete-filled steel tube and concrete technology, which is used in arch bridges, bridges, bridge materials, etc., can solve the problems of hollowing out of steel tubes and concrete, affecting the bearing capacity of concrete-filled steel tubes, and affecting the quality of concrete pouring in tubes, so as to reduce damage and avoid hollowing out of steel tubes. Phenomenon, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

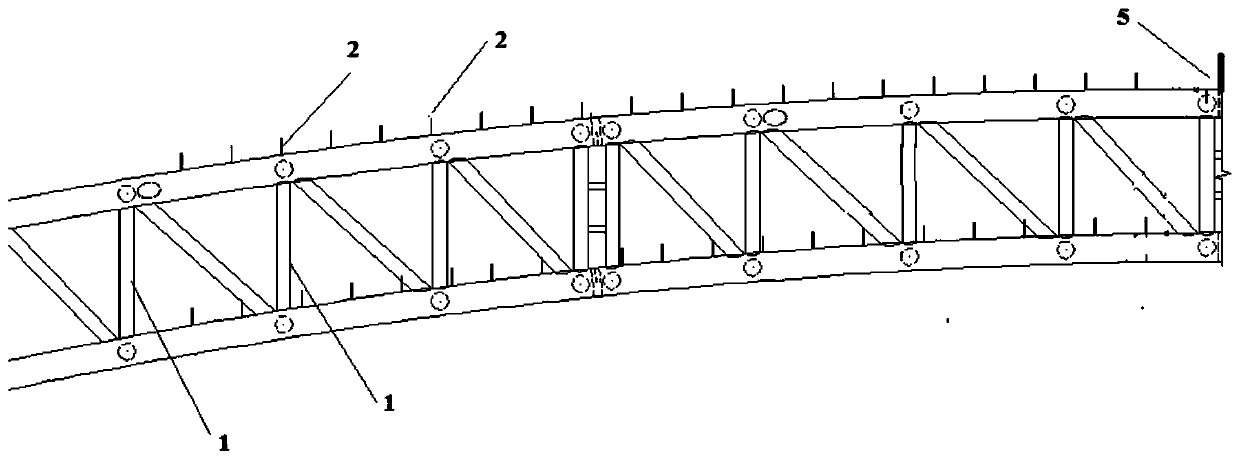

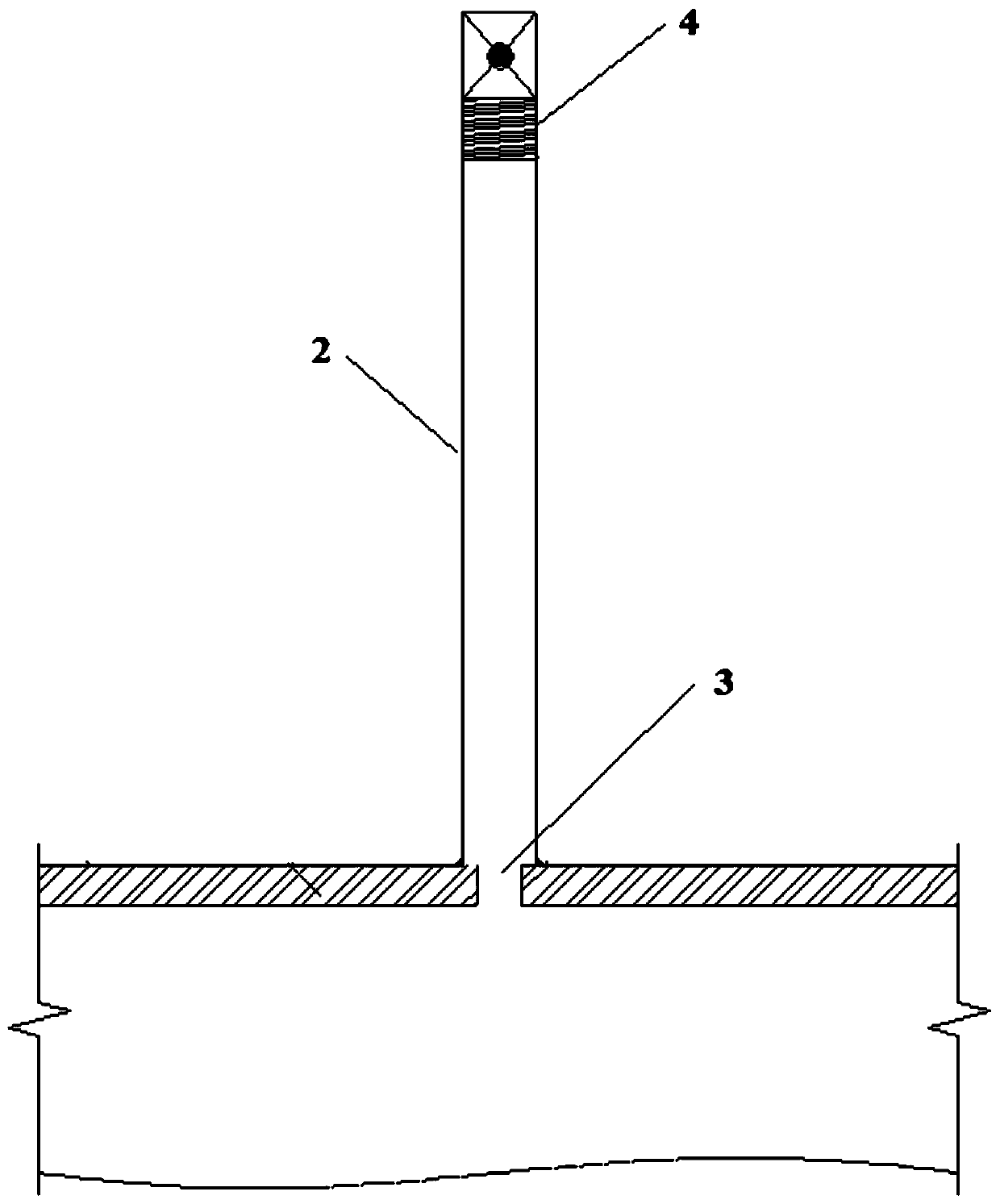

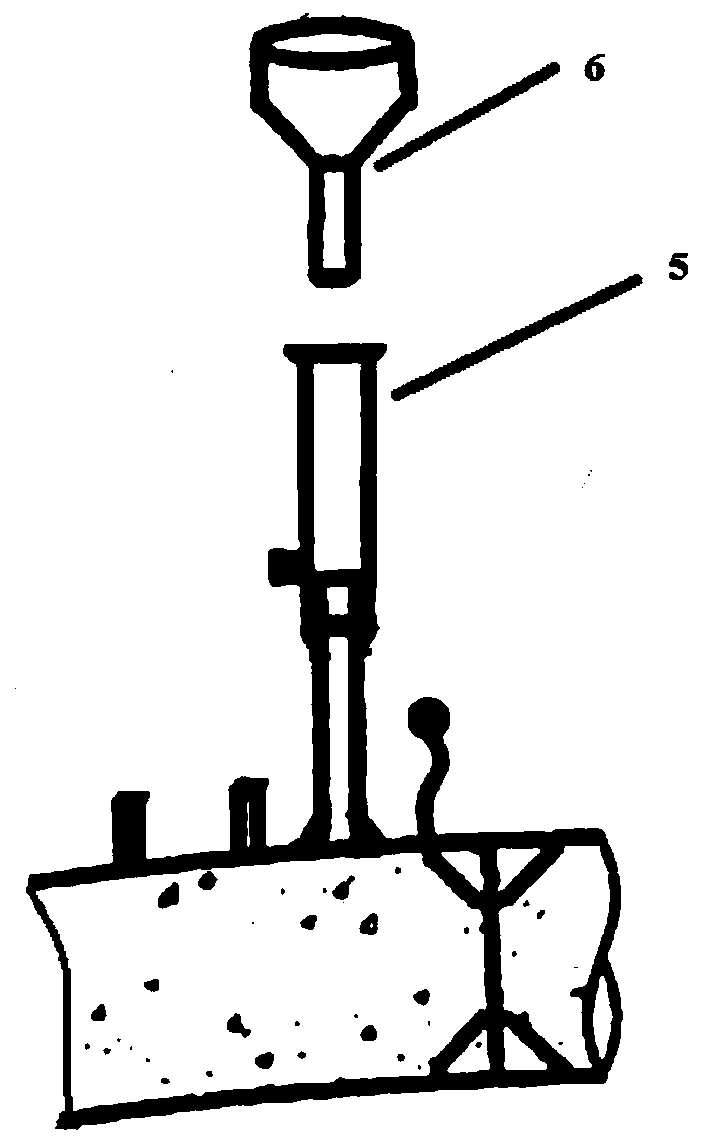

[0040] Such as figure 1 According to the arch rib exhaust construction layout drawing, several vent holes are added on the steel pipe adjacent to the arch rib vault. Steel pipe, the angle between the tangent line of the steel pipe and the horizontal plane is less than 5°; the exhaust pipe is arranged on the exhaust hole, figure 1 Three exhaust pipes 2 are arranged between every two vertical web bars 1, and the distance between the two vertical web bars 1 is about 7.5m. Each exhaust pipe 2 is responsible for the exhaust in the range of 2.5m. figure 2 As shown, the diameter of the exhaust hole 3 is about 48 mm, and the exhaust hole 3 is designed as a free switch device 4 .

[0041] After the arch rib is evacuated to -0.08MPa~-0.06MPa negative pressure, maintain this negative pressure to pour concrete into the arch rib. The slurry pipe discharges qualified concrete. At this time, open the vent hole 3 at the end, and insert a micro vibrator into the vent hole 3 for vibration. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com