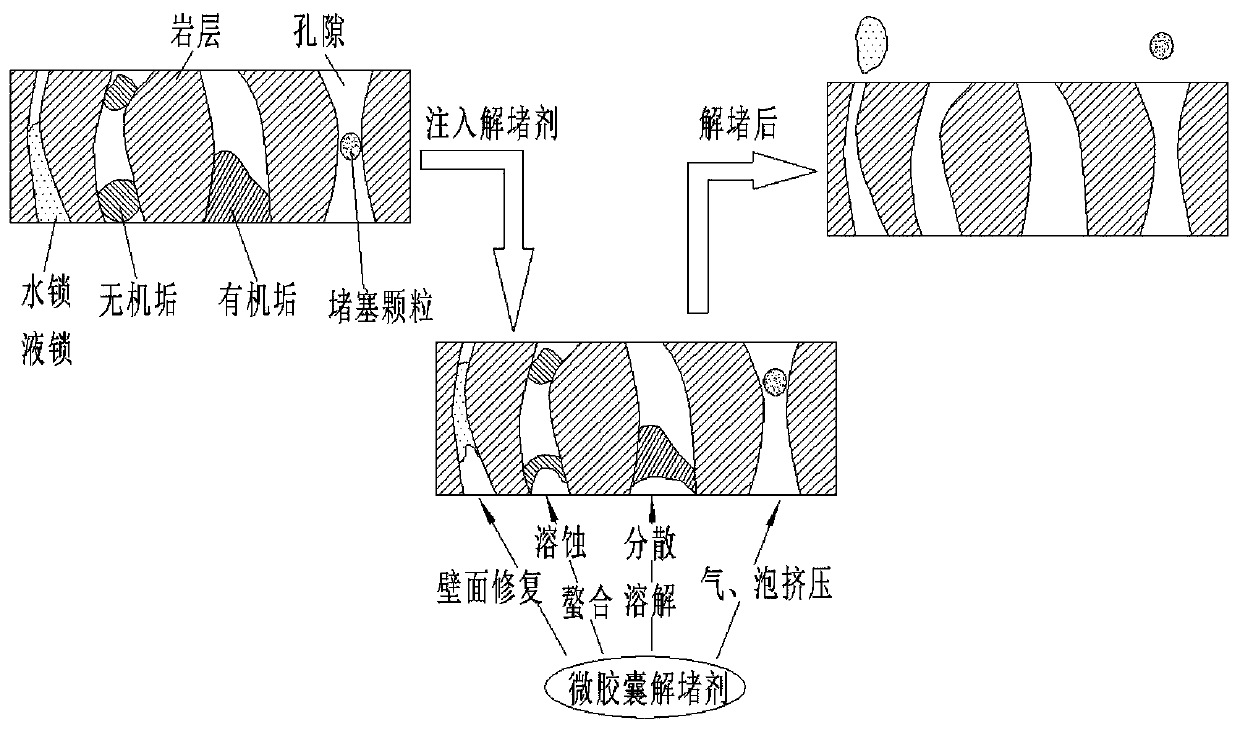

Oil field microcapsule non-acid self-generating thermal blocking remover and preparation method thereof

A technology of microcapsules and plugging remover, which is applied in the field of oil field microcapsule non-acid autogenous heat plugging remover and its preparation, can solve the problems of safety hazards, reaction heat release, etc., and achieve increased pressure, increased crude oil production, social benefits and Significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned oilfield microcapsule non-acid self-generated heat plugging remover is specifically:

[0048] The water-soluble microcapsule plugging remover KR-100A and the water-soluble microcapsule plugging remover KR-100B are uniformly mixed according to the mass ratio of 0.9-2.1:1 to obtain the oilfield microcapsule non-acid autogenous heat plugging remover.

[0049] The specific steps for using the above-mentioned oilfield microcapsule non-acid self-generated heat plugging remover are as follows:

[0050] Use clean water to test the pressure of the extrusion process and the Christmas tree to ensure that there is no puncture or leakage, and the extrusion construction will be carried out after passing the test;

[0051]Close the blowout preventer, test squeeze the perforation section, and determine the water absorption of the oil layer;

[0052] Disperse the mixture of water-soluble microcapsule deblocking agent KR-100A and water-solub...

specific Embodiment

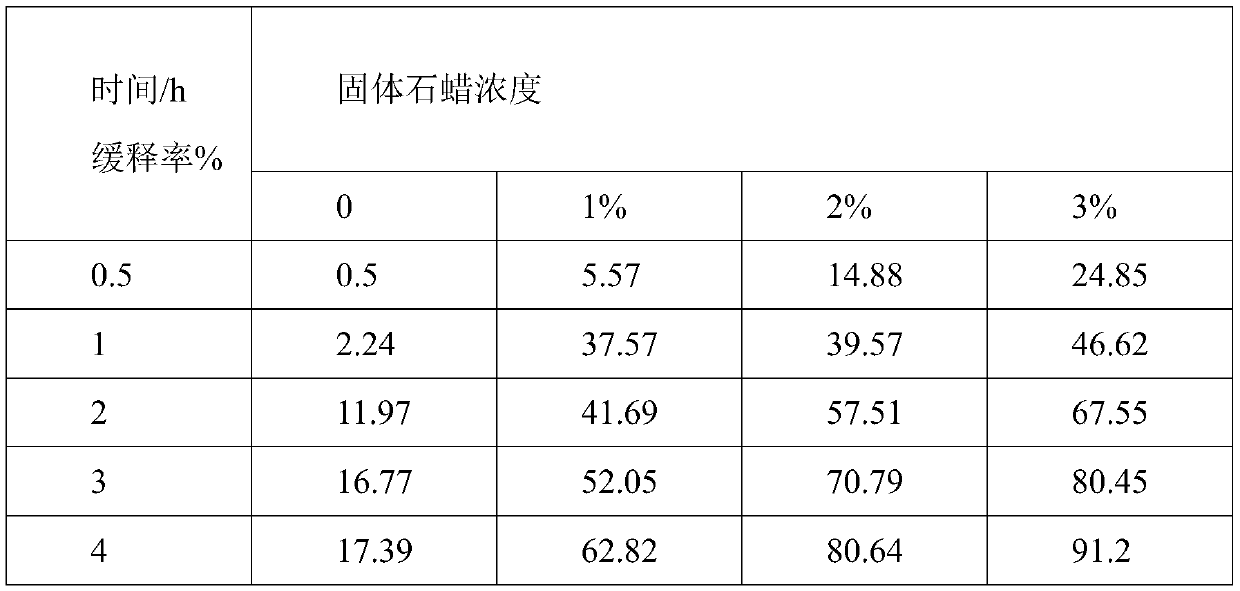

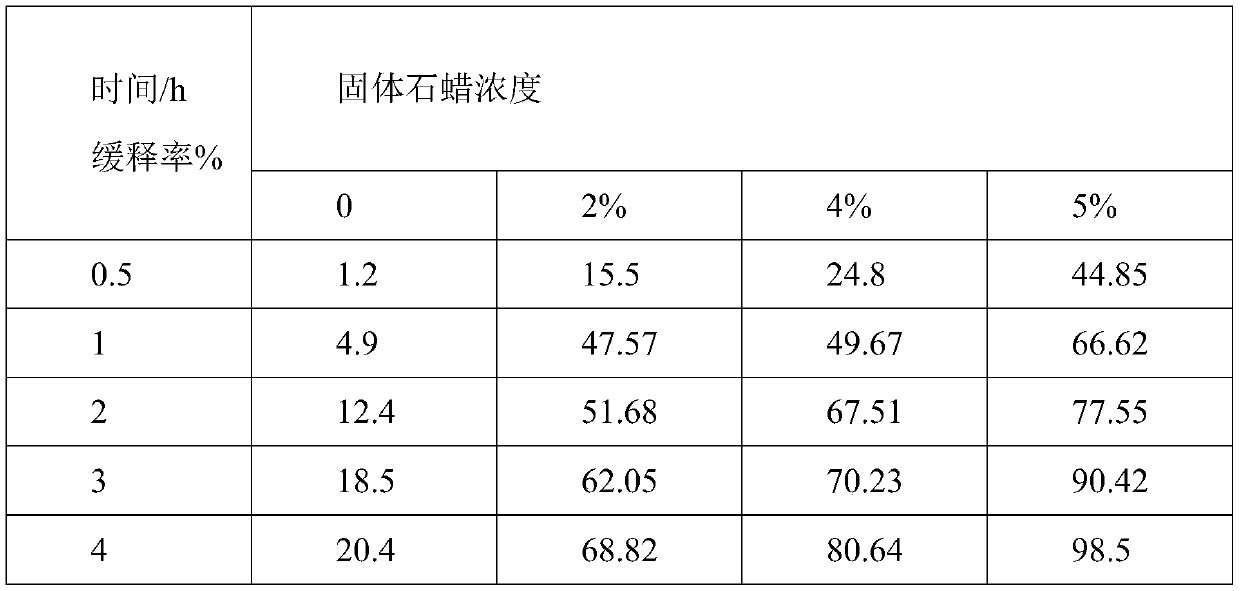

[0061] Preparation of water-soluble microcapsule deblocking agent KR-100A: Add 300 parts of capsule core material ammonium chloride and 100 parts of potassium chloride to 1000 parts of water to dissolve to saturation. After filtering, add the saturated aqueous solution into a stainless steel reaction kettle, add sulfuric acid Adjust the pH to 2, heat the reactor to 50°C, add 200 parts of polyvinyl alcohol with a degree of polymerization of 3000 and a degree of alcoholysis of 80mol1% and stir evenly, add 40 parts of dimethyl sulfoxide and 10 parts of solid paraffin, and place in a high-speed mixer , heat up to 120°C, react for 2.5 hours, cool to room temperature, filter, wash with absolute ethanol, and dry to obtain the water-soluble microcapsule unblocking agent KR-100A, which has a particle size of 0.1-0.9mm and a release rate > 60%, the effective content can reach 39.23%, and the embedding rate is 86.77%.

[0062] Table 1 The influence of solid paraffin on KR-100A slow-relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| solubility temperature | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com