Gypsum-based self-leveling repair mortar and preparation method thereof

A repairing mortar and self-leveling technology, which is applied in the field of gypsum building materials, can solve the problems of gypsum-based self-leveling ground cracks and incomplete repairs, and achieve the effects of convenient repairs, cost-saving ground repairs, and rapid repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

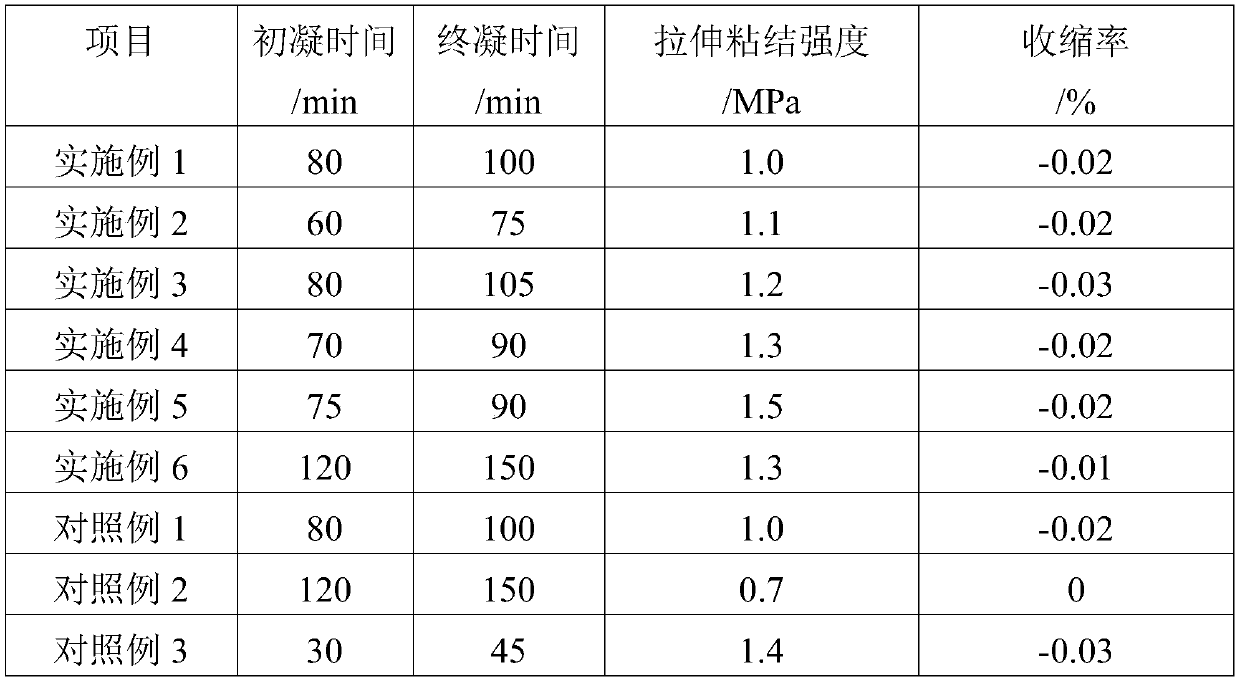

Examples

preparation example Construction

[0042] In order to further understand the gypsum-based self-leveling repair mortar of the present invention, the present invention also provides a preparation method of the gypsum-based self-leveling repair mortar, the preparation method comprising the following steps:

[0043] Step 1: Weigh construction gypsum, quartz sand and stone powder in a container according to the proportion, stir and mix evenly, then add gypsum retarder, water retaining agent, rubber powder, defoamer and water reducer in sequence, stir and mix evenly to obtain dry powder;

[0044] Step 2: Add a certain amount of water into the dry powder obtained in Step 1, stir and mix evenly, and obtain gypsum-based self-leveling repair mortar.

[0045] In a specific embodiment of the present invention, the preparation method of building gypsum in step 1 is: calcining desulfurized gypsum at 160-165°C (such as 160°C, 161°C, 162°C, 163°C, 164°C, 165°C) for 1-2 hours (such as 1h, 1.1h, 1.2h, 1.3h, 1.4h, 1.5h, 1.6h, 1.7h...

Embodiment 1

[0049] This embodiment provides a gypsum-based self-leveling repair mortar, in parts by weight, the formula of the gypsum-based self-leveling repair mortar is: 40 parts of building gypsum, 50 parts of quartz sand, 10 parts of stone powder, 0.1 part of gypsum retarder, 0.01 part of water retaining agent, 0.01 part of rubber powder, 0.1 part of defoamer, 0.1 part of water reducing agent, 25 parts of water.

[0050] Among them, the preparation method of the building gypsum is: calcining the desulfurized gypsum at 160° C. for 2 hours, cooling to room temperature, grinding it in a ball mill, and aging for 6 days to obtain the building gypsum.

[0051] The preparation method of gypsum-based self-leveling repair mortar in this embodiment is as follows:

[0052] Step 1: Weigh 400kg of construction gypsum, 500kg of quartz sand and 100kg of stone powder in a container according to the proportioning ratio, and after stirring and mixing evenly, add 1kg of composite retarder (mixed with ta...

Embodiment 2

[0057] This embodiment provides a gypsum-based self-leveling repair mortar. In parts by weight, the formula of the gypsum-based self-leveling repair mortar is: 45 parts of building gypsum, 45 parts of quartz sand, 10 parts of stone powder, 0.1 part of gypsum retarder, 0.01 part of water retaining agent, 0.01 part of rubber powder, 0.1 part of defoamer, 0.1 part of water reducing agent, 25 parts of water.

[0058] Among them, the preparation method of the building gypsum is: calcining the desulfurized gypsum at 160° C. for 2 hours, cooling to room temperature, grinding it in a ball mill, and aging for 6 days to obtain the building gypsum.

[0059] The preparation method of gypsum-based self-leveling repair mortar in this embodiment is as follows:

[0060] Step 1. Weigh 450kg of construction gypsum, 450kg of quartz sand and 100kg of stone powder in a container according to the proportioning ratio. After stirring and mixing evenly, add 1.0kg of composite retarder (mixed with tart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com