Plate feeding machine for brick machine system

A technology of loading machine and brick machine, which is applied in the field of loading machine, can solve the problems of insufficient automation of loading machine, affect the production efficiency of the brick machine system, and increase the production cost of brick making, so as to achieve compact and reasonable structural design and improve production efficiency , the effect of structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given in detail.

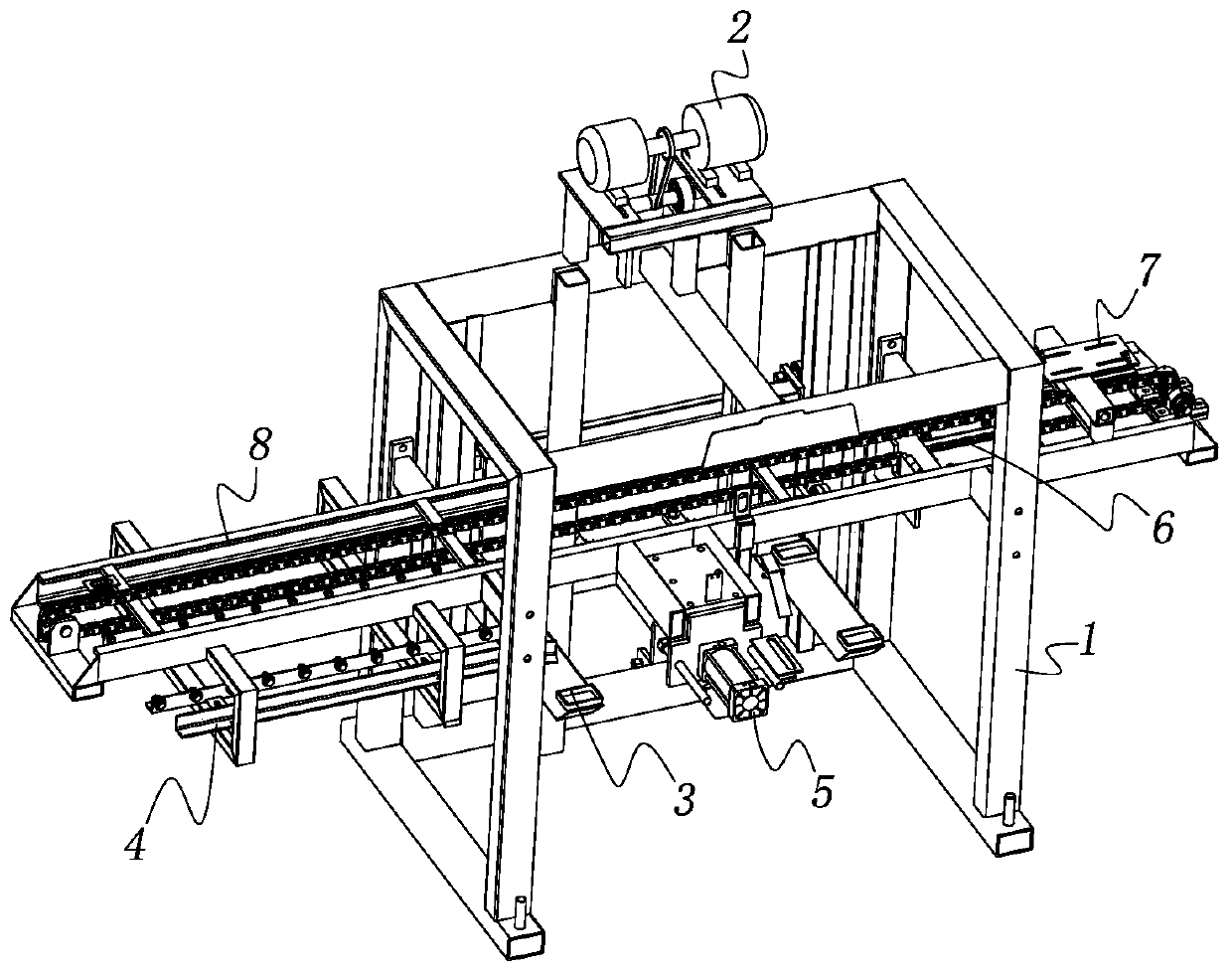

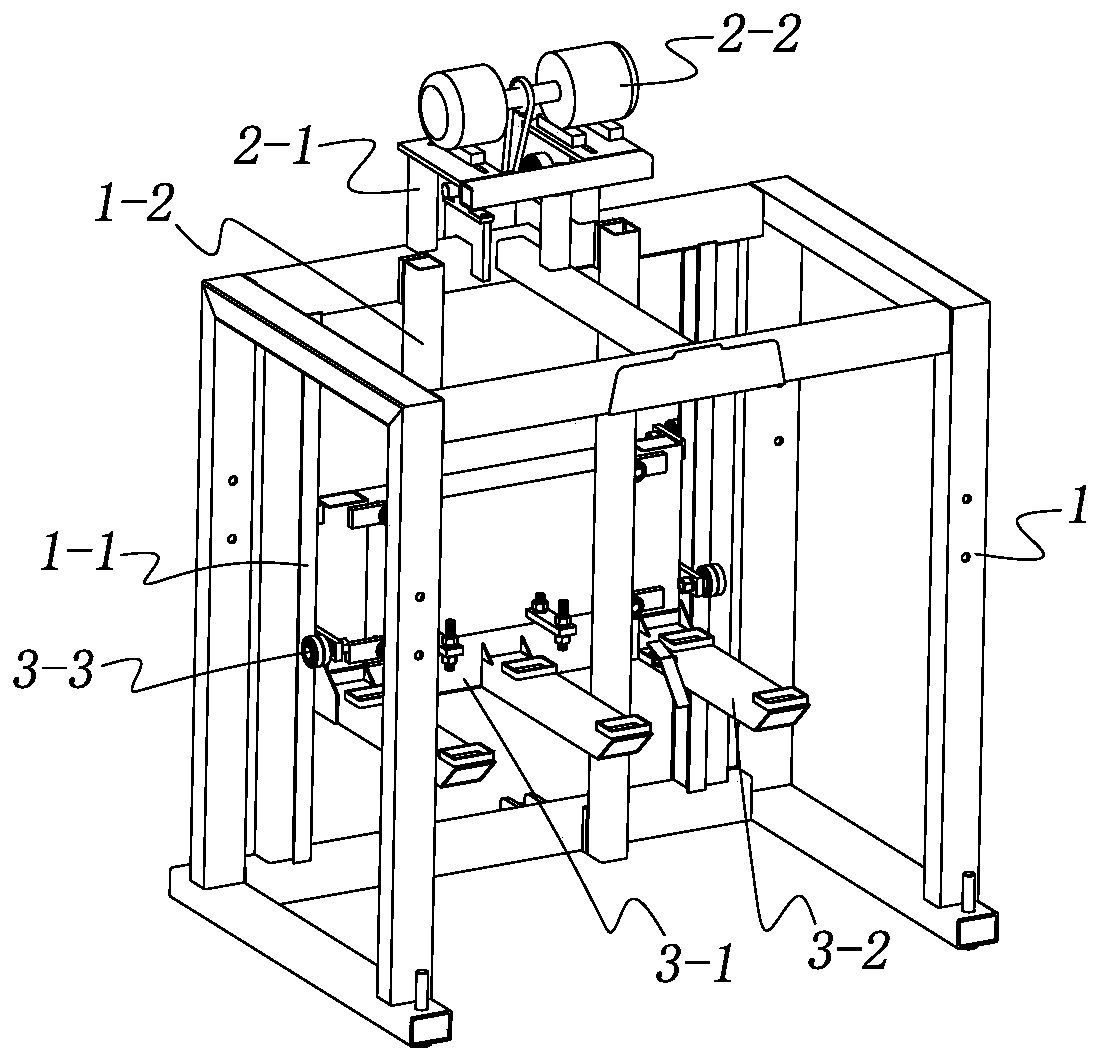

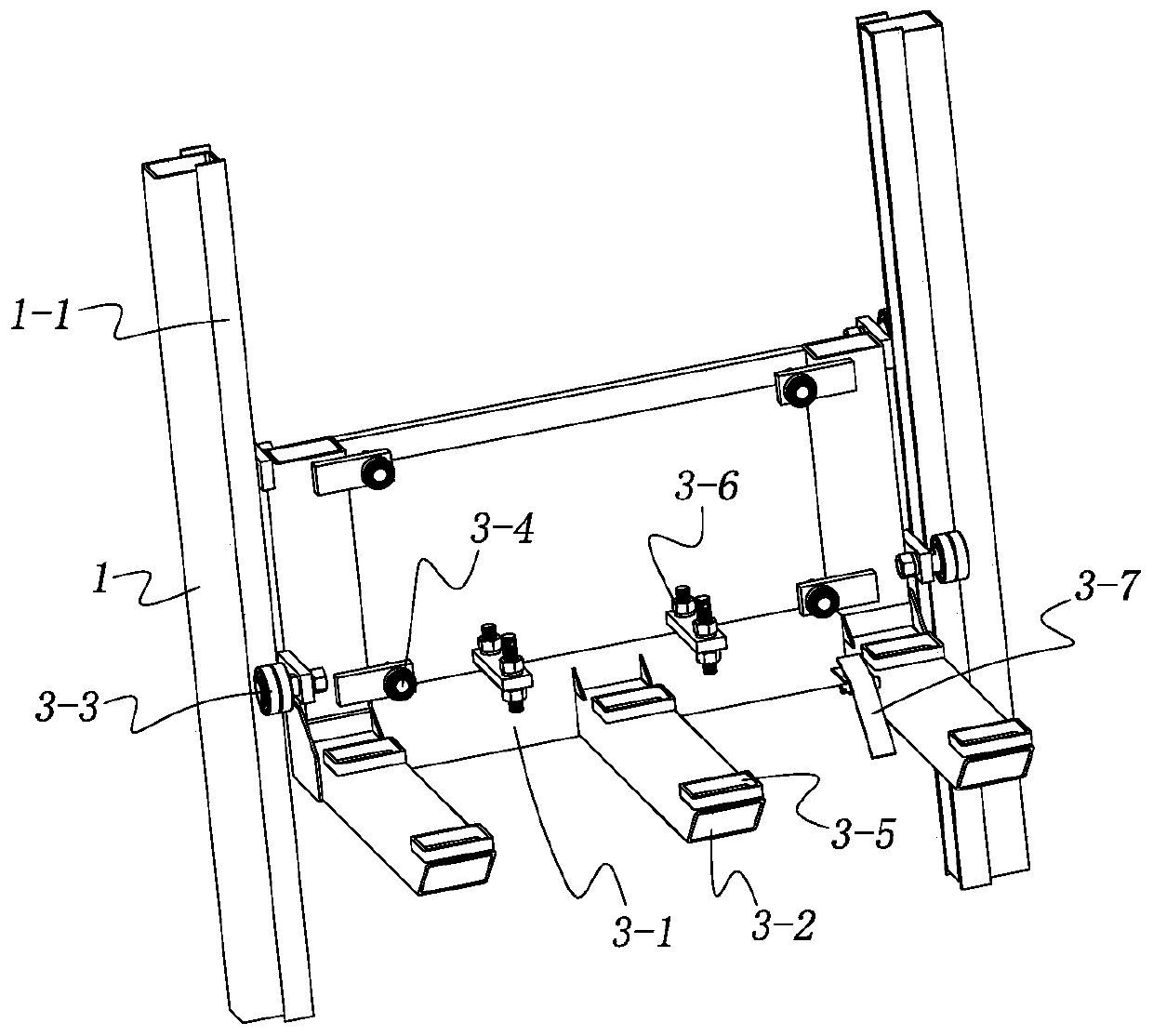

[0026] See figure 1 and figure 2 , the loading machine for the brick machine system of the present invention includes a frame 1, a frame device 8 is installed in the middle of the frame 1, a carrying device 3 is installed on the back, and a lifting drive device 2 is installed on the top, the carrying device 3 is used for The stacked multi-layer brick pallets are loaded, and the lifting drive device 2 drives the carrying device 3 to move up and down. A guide device 4, a top board device 6 and a conveying device 7 that drives the top board device 6 to move in translation are installed on the frame device 8, and an alignment device 5 is also installed at the middle part of the frame device 8, wherein the guide device 4 is used for supporting the brick board. Guided to ensure the accuracy of the moving position, the top plate device 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com