Adjustable thickening machine for pearl wool

A pearl cotton and adjustable technology, which is applied in the field of adjustable thickening machine for pearl cotton, can solve the problems of reducing cost and increasing the thickness of pearl cotton, and achieves the effect of saving cost, reducing production input and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

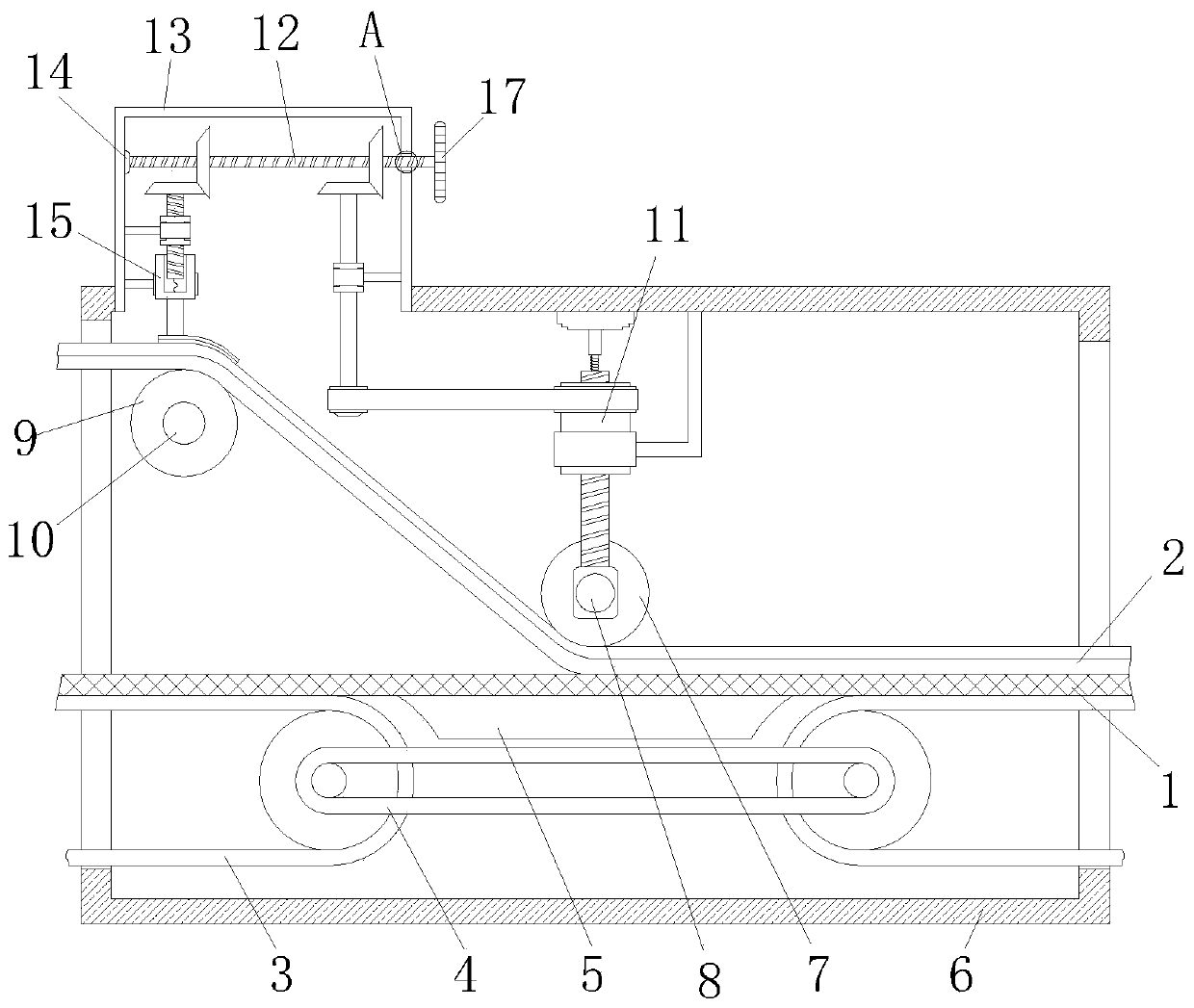

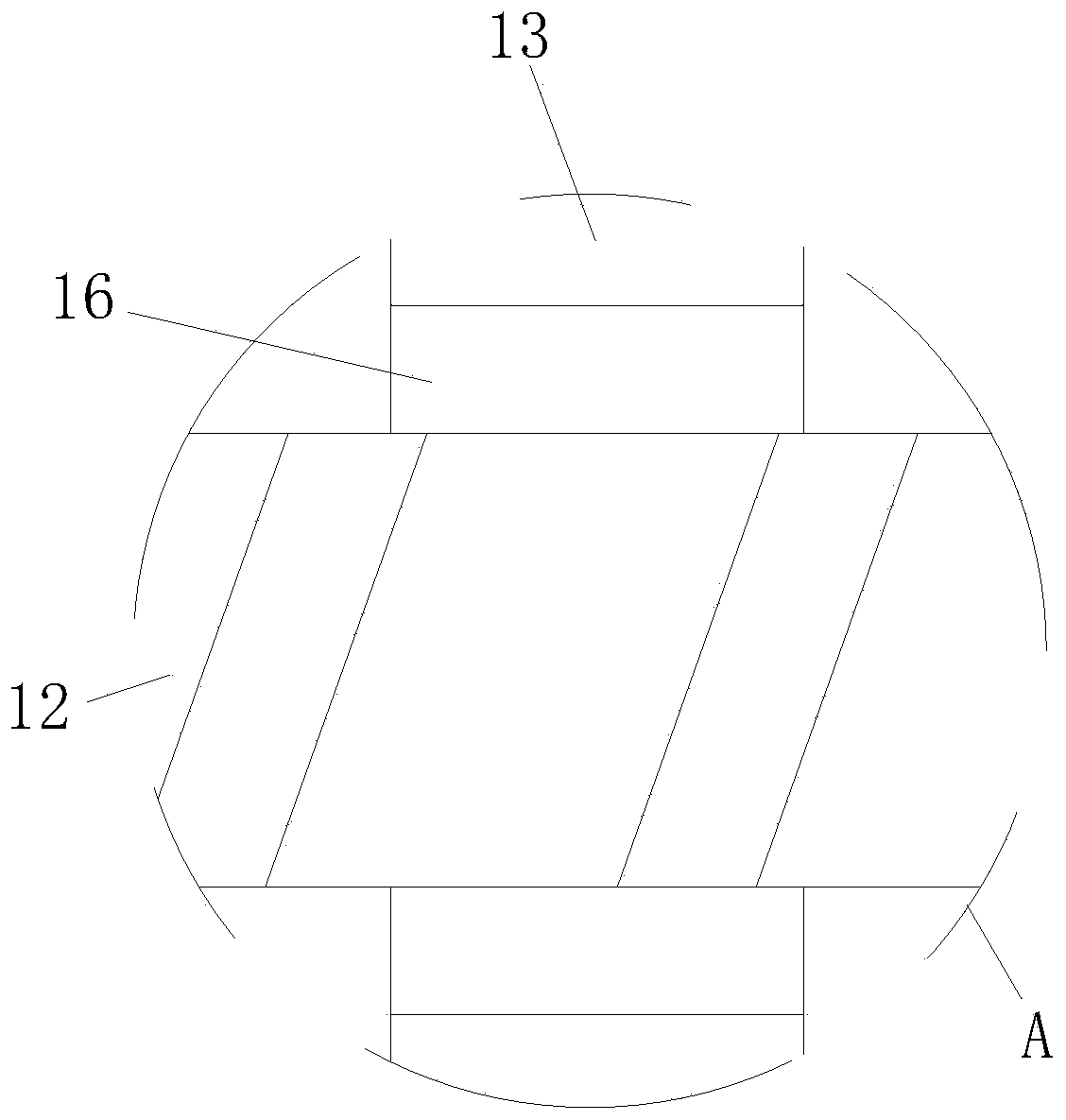

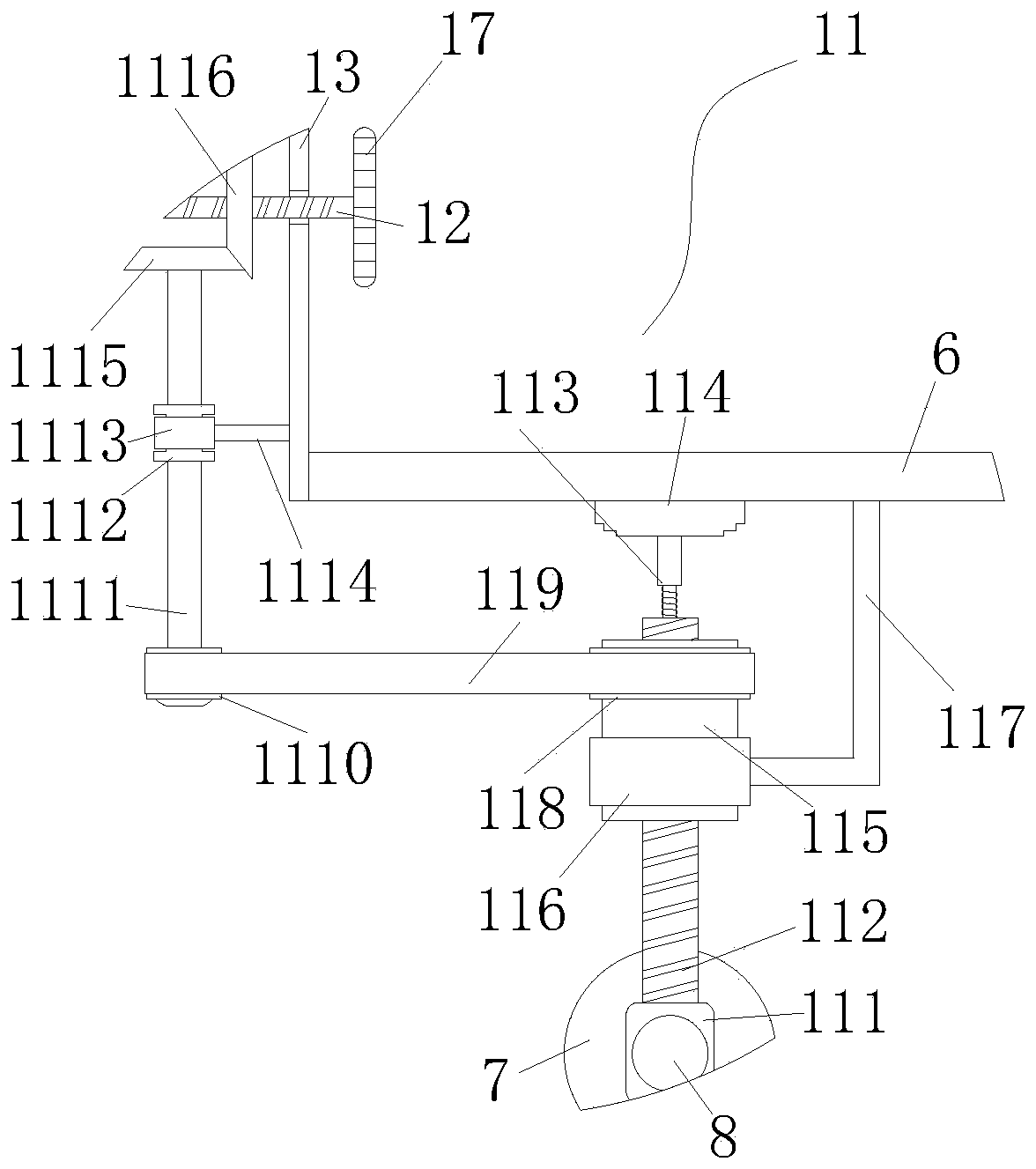

[0052] An adjustable thickening machine for pearl cotton, see figure 1 , the thickening machine includes: a driving mechanism 3, a belt 4, a heating plate 5, a support frame 6, a pressing roller shaft 7, a supporting roller shaft 9, a No. 1 adjustment connecting part 11, an adjustment screw 12, and a support frame 13 And No. 2 adjustment connection part 15.

[0053] The support structure 6 has a layout chamber with two ends connected through, one end of the layout chamber is the input end, and the other end is the output end, and the side wall is provided with an installation opening near the input end, and the support frame 13 is fixed on the installation opening The edge is connected with the layout chamber of the supporting structure 6 .

[0054] The thickened pearl cotton 2 partially covers the upper surface of the thickened pearl cotton 1, and the thickened pearl cotton 1 is arranged on two symmetrically arranged drive mechanisms-3 to support and transmit it, ensuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com