Portable wall grinder and method of use thereof

A grinding machine and portable technology, applied in the direction of grinding machine parts, machine tools suitable for grinding workpiece plane, grinding machines, etc., can solve the problems of difficult to guarantee grinding accuracy, low construction efficiency, poor construction quality, etc. The effect of overflow, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

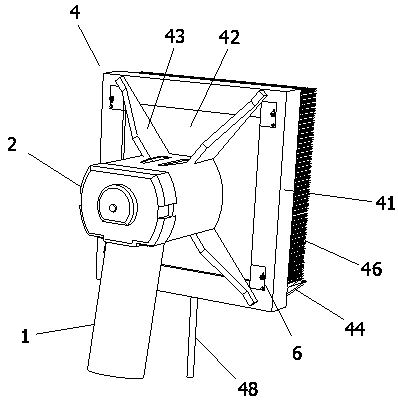

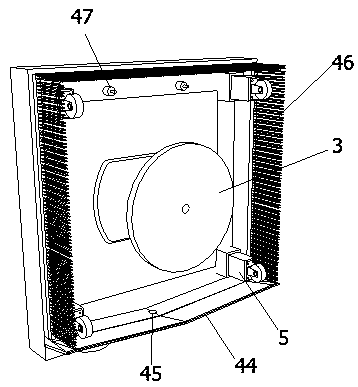

[0050] combinefigure 1 and figure 2 As shown, a portable wall grinder provided by this embodiment includes a handle 1 , a drive motor 2 and a grinding cutter head 3 , and also includes a dust cover 4 , several hydraulic buffer components 5 and a grinding depth adjustment component 6 .

[0051] The back of the dust cover 4 is fixed on the casing of the drive motor 2 , and the grinding cutter head 3 is located on the front of the dust cover 4 and is fixedly connected with the transmission shaft of the drive motor 2 . Further, the dustproof cover 4 includes a hard outer frame 41, a transparent plate 42 and a rib 43, and the positions of the four corners of the hard outer frame 41 are fixedly connected to the casing of the drive motor 2 through a rib 43 respectively, The rigid outer frame 41 is a rectangular frame composed of plates with an L-shaped cross section, and the transparent plate 42 is fixed in the rigid frame. The transparent plate 42 can be sleeved on the casing of t...

Embodiment 2

[0061] This embodiment provides a method for using a portable wall grinder, using the grinder in Embodiment 1, according to the following Figure 10 to Figure 12 , and combined with Figure 1 to Figure 9 The method of use is further described. The method of use comprises the steps of:

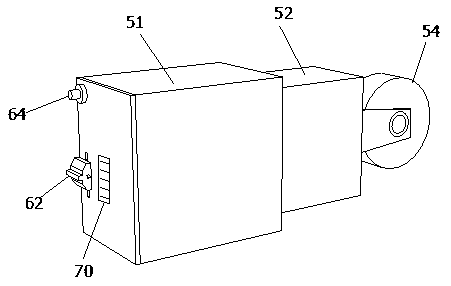

[0062] Step 1. Determine the depth to be polished on the wall, adjust the position of the step-shaped limit card 61 through the adjustment button 62, and set all the grinding depth adjustment components 6 of the grinder to the required grinding depth;

[0063] Step two, such as Figure 10 As shown, start the grinder, and gradually press the grinder to the wall 8 to grind out a circular groove, such as Figure 11 As shown, when the grinding depth of the grinding machine reaches the maximum, move the grinding machine downward along the wall 8, and grind to form a vertical strip groove;

[0064] Step three, such as Figure 12 As shown, the grinder is moved to the adjacent area to be polished,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com