Garbage treatment system

A garbage disposal system and garbage technology, which are applied in grain processing, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of low garbage disposal efficiency, easy connection into clusters, waste of resources, etc., and achieve smooth crushing process, not easy to stick. connection phenomenon, the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A garbage treatment system, including a first garbage crushing device 10, a second garbage crushing device 20, a group breaking device 30, a screen device 40, and a digester 50. Taking kitchen and domestic waste as an example, the specific implementation of the present invention is described in detail The way is as follows:

[0040] The first crushing device 10 and the second crushing device 20 perform front-end crushing of garbage.

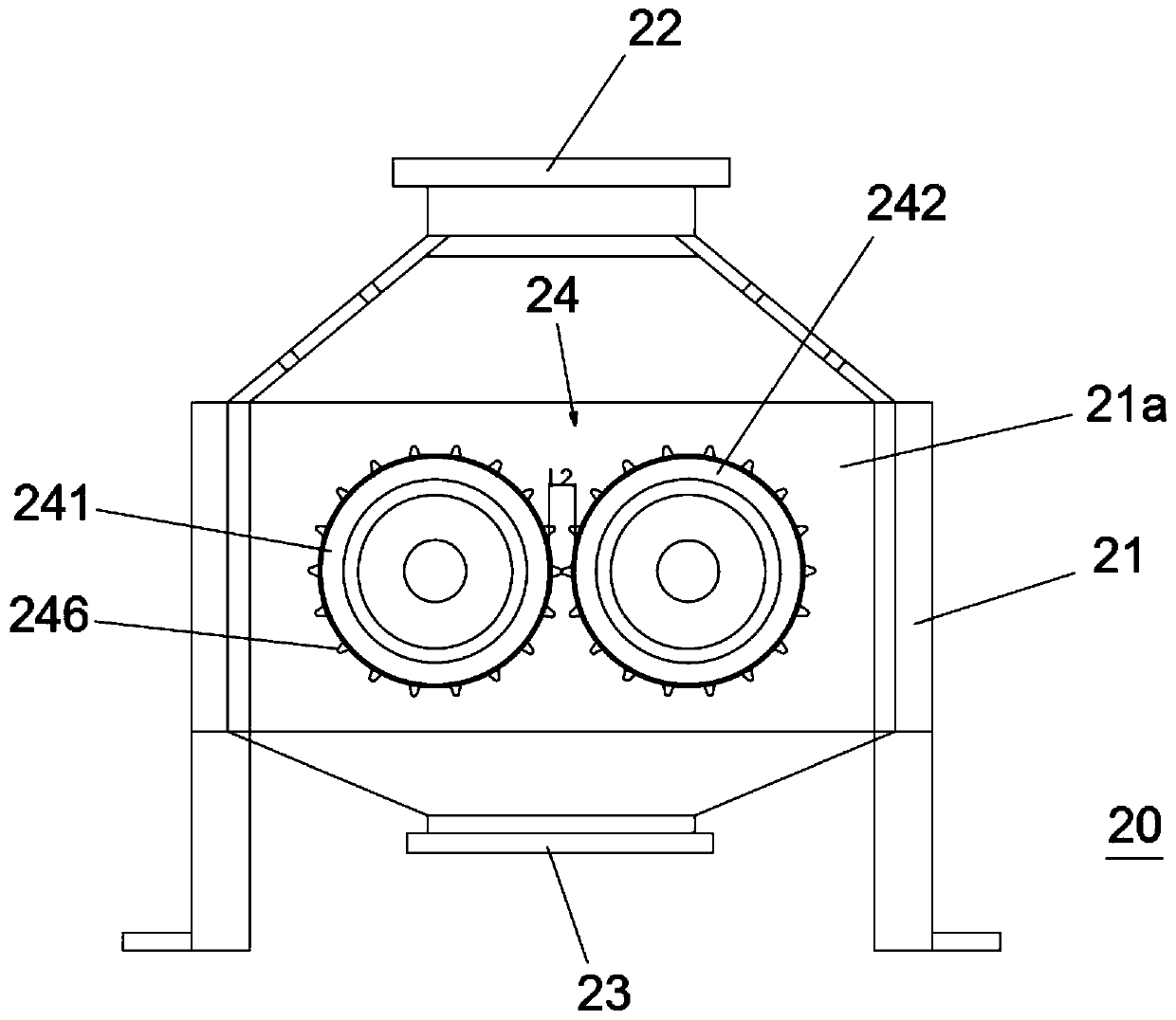

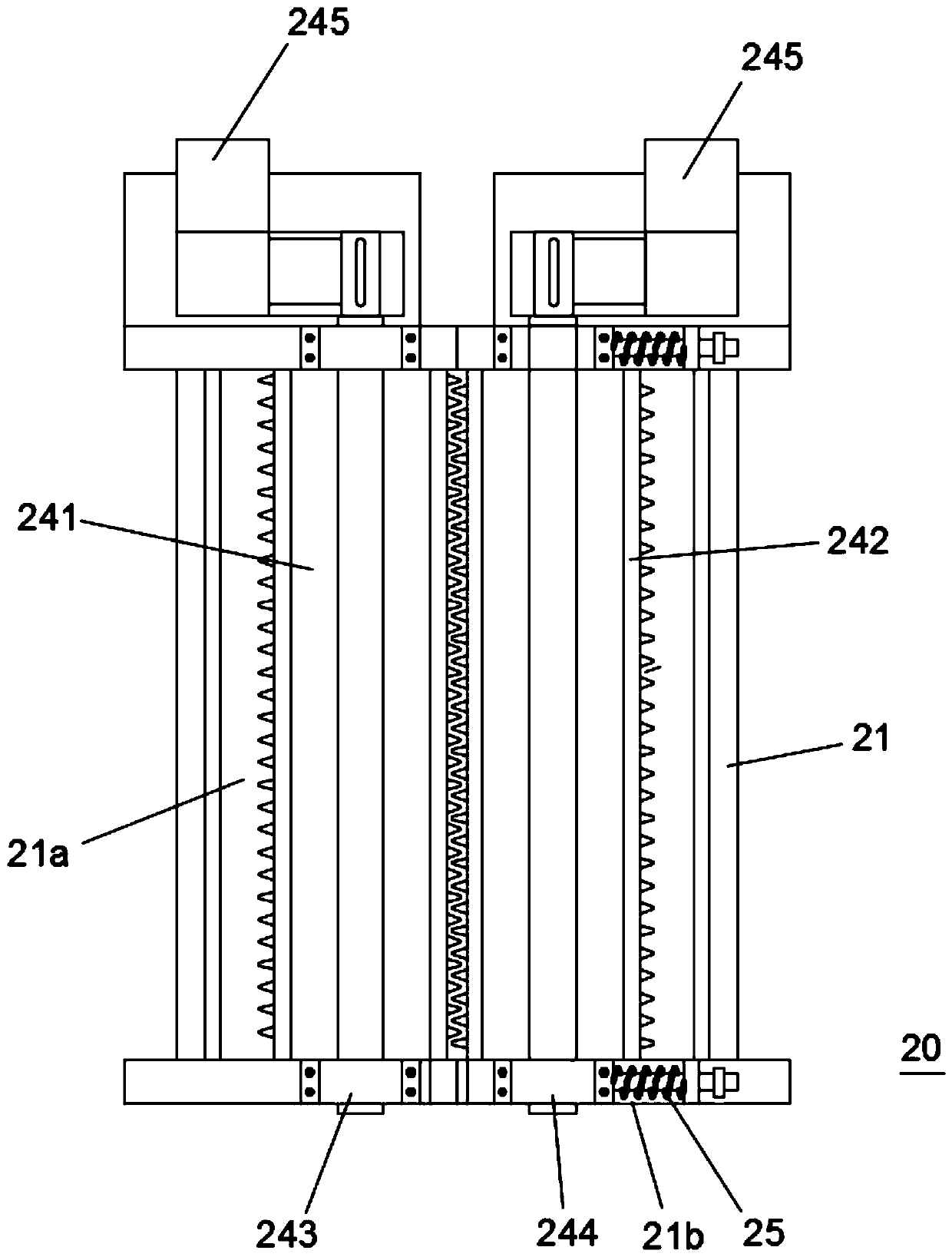

[0041] Wherein, the first crushing device 10 is used for coarse crushing of kitchen waste, and the second crushing device 20 is used for fine crushing of kitchen waste. In this example, a water injection device is also provided, and the water injection device is used for first The crushing device 10 and the second crushing device 20 inject an appropriate amount of water during the process of processing and crushing food waste.

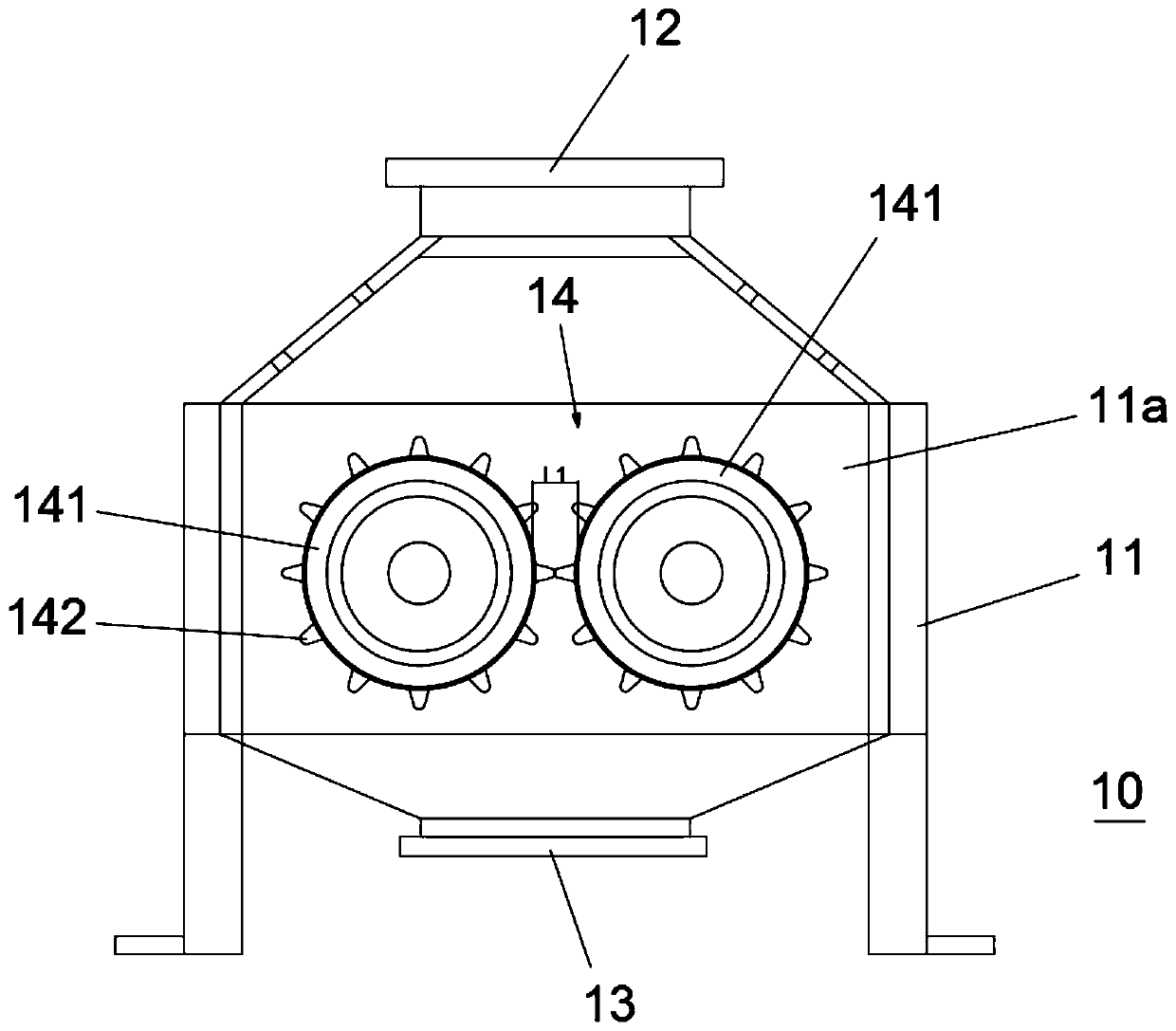

[0042] see figure 1 , the first crushing device 10 includes a first frame 11, a coarse crushing chamber 11a is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com