Extruding type silkworm cooking feed extrusion device and use method thereof

An extrusion device and extrusion technology, applied in the field of silkworm breeding, can solve problems such as low efficiency, and achieve the effects of convenient operation, high efficiency and high feed extrusion molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

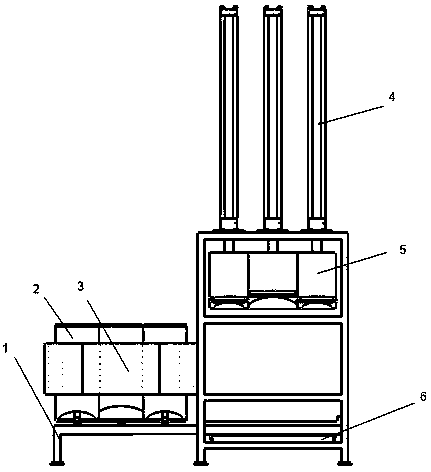

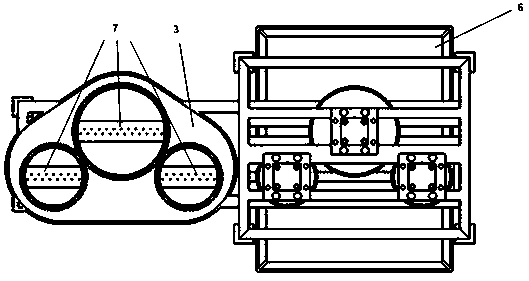

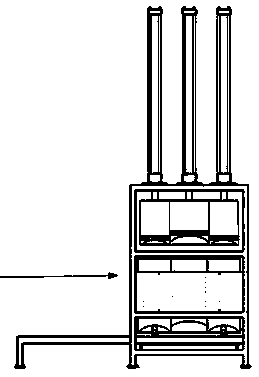

[0027] Such as figure 1 Shown is an extrusion type silkworm cooking feed extrusion device, comprising a frame 1 provided with a transverse guide rail, a material cylinder 2 slidably connected to the transverse guide rail, and a material cylinder 2 fixedly provided with a discharge material arranged along the lateral direction in the material cylinder. Plate 7, a discharge hole is provided on the discharge plate, and the feed outlet of the feed cylinder is below the discharge hole. There are three material cylinders in this embodiment, and the three material cylinders are fixedly connected as a whole through material cylinder sleeves 3, and rollers supported on the guide rails are installed on each material cylinder. The material cylinder liner consists of two sets of plates fixed in one body, the purpose is to limit the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com