Double-layer circuit and manufacturing method thereof

A manufacturing method and circuit technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of low production efficiency of liquid metal double-layer circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

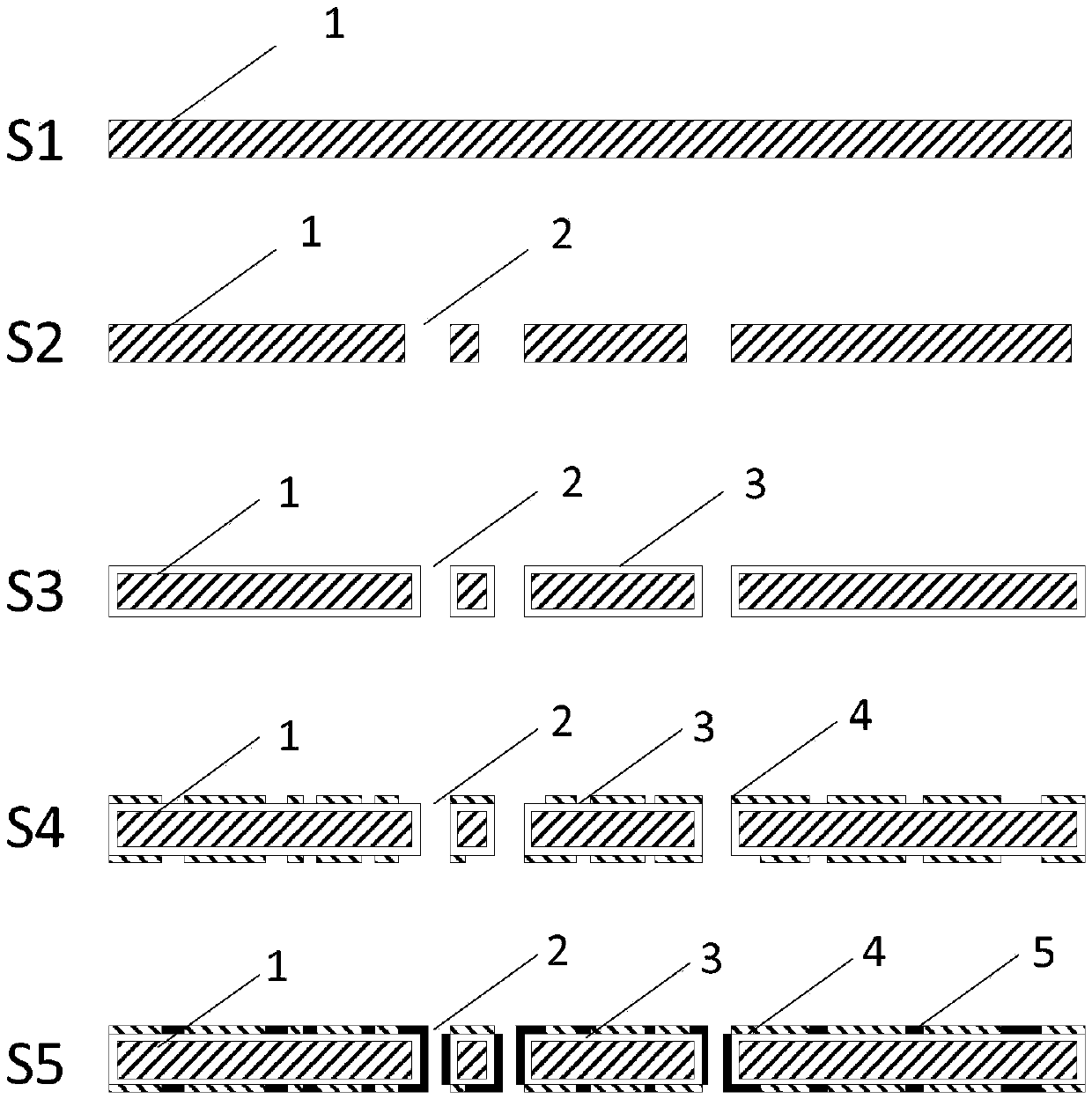

Method used

Image

Examples

Embodiment approach 1

[0042] Step a, select PET film as the base material, the thickness of the base material is 200 μm;

[0043] Step b, drilling required via holes on the base material;

[0044] Step c, performing surface treatment on the base material, cleaning both sides of the base material and the inner wall of the via hole;

[0045] Step d, immersing the base material in the polyurethane colloid for 15 seconds, drying and curing after taking it out, forming a surface modification layer of 50 μm on the surface of the base material;

[0046] Step e, forming a solder resist layer on the surface modification layer on both sides of the base material by laser printing toner; wherein, the solder resist layer includes a silk screen layer of the circuit;

[0047] Step f, put the substrate into the liquid metal coating device and use the roller set to coat the liquid metal on both sides of the substrate; wherein, the liquid metal on the inner wall of the via hole is squeezed into the via hole by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com