Control method suitable for preheating of power battery of direct-current quick-charging pile

A DC fast charging pile and power battery technology, applied in charging stations, secondary batteries, electric vehicle charging technology, etc., can solve the problem of not supporting the pure preheating function of the battery, unfriendly car experience, and inability to achieve pure heating, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below based on the drawings. In addition, this invention is not limited at all to embodiment described below, As long as it has substantially the same structure as this invention, and can exhibit substantially the same effect, various changes are possible.

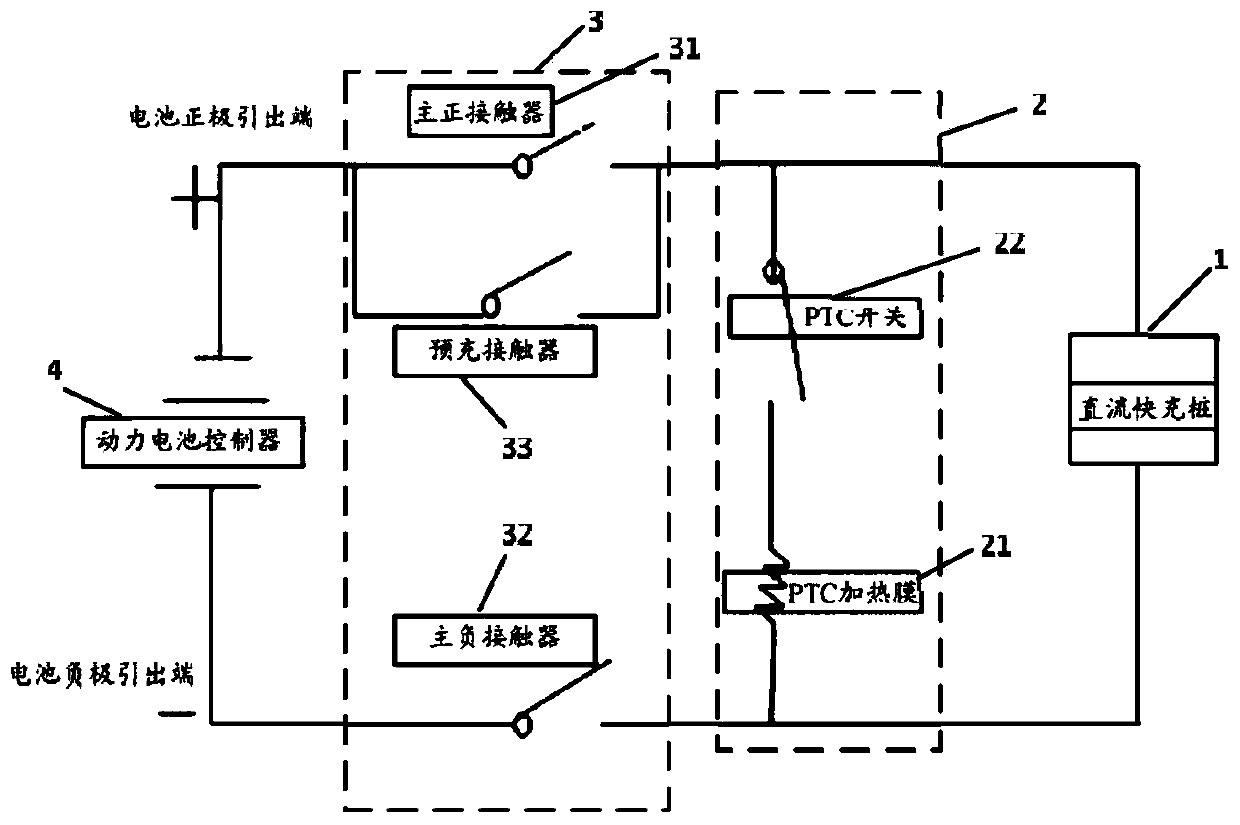

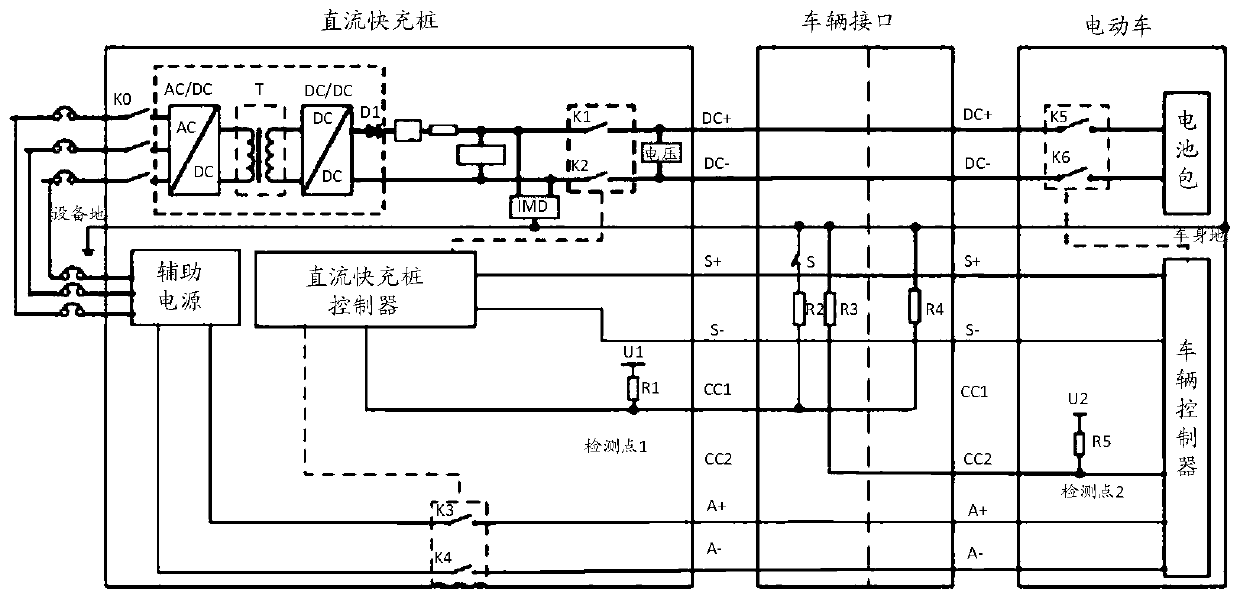

[0019] figure 1 It is a schematic diagram showing the physical connection of the power battery preheating control system suitable for DC fast charging piles according to the embodiment of the present invention. Such as figure 1 As shown, the power battery preheating control system includes: DC fast charging pile 1, battery preheating system 2, battery pack 3, and power battery controller (Battery Management System, hereinafter referred to as BMS) 4. The battery preheating system 2 is actually installed in the battery pack 3 , which includes: a PTC (Positive Temperature Coefficient: positive temperature coefficient) heating film 21 for heating the power battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com