Machining equipment error correction method and system based on single machine

A processing equipment and error technology, which is applied in the field of error correction of processing equipment based on a single machine, can solve the problems such as the inability to realize the realization of intelligent factories and the consumption of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

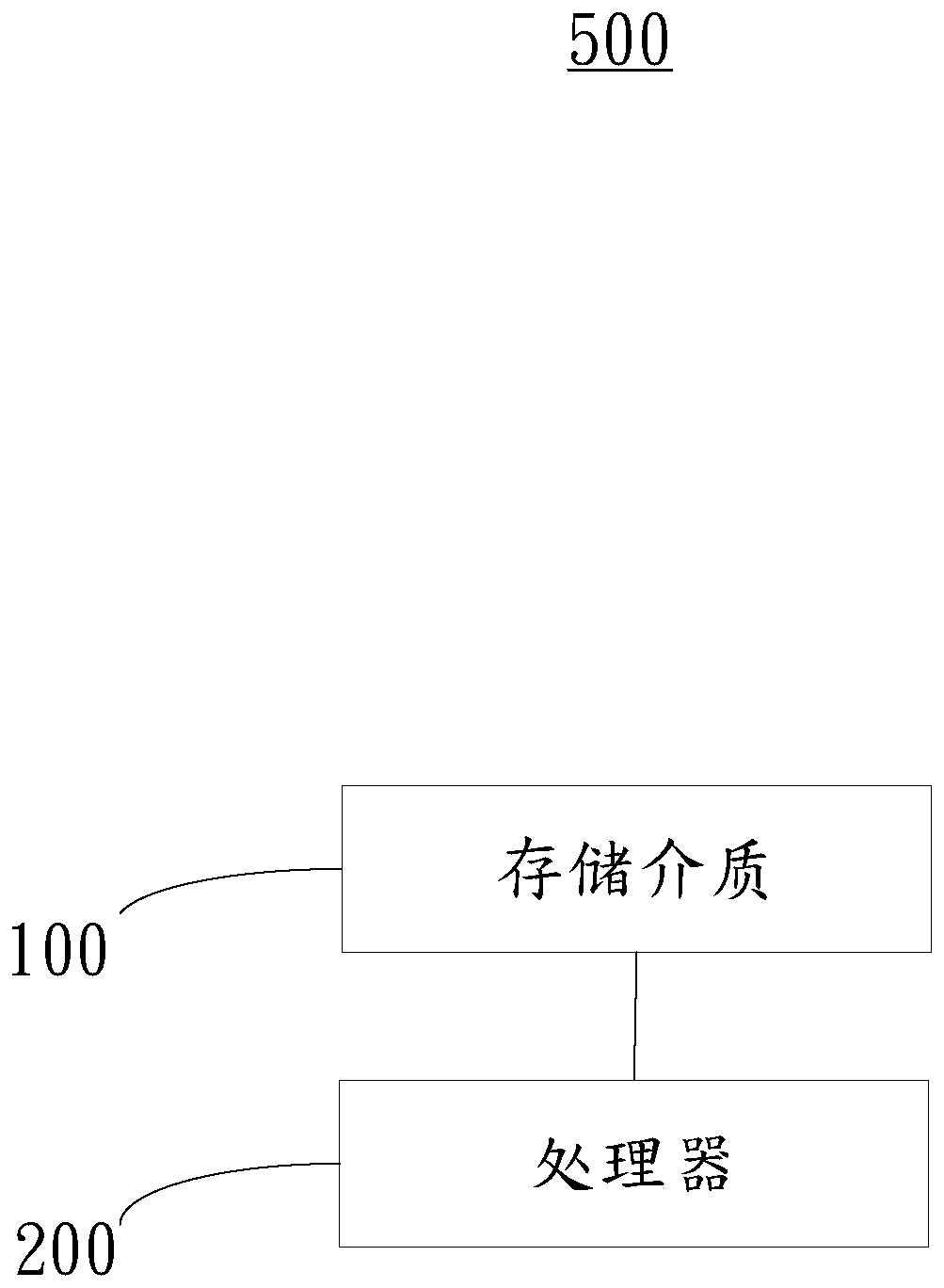

[0062] Such as figure 1 As shown, the processing equipment error correction system 500 includes a processor 200 and a storage medium 100 .

[0063] A plurality of instructions are stored in the storage medium 100, and the instructions are suitable for being loaded by the processor 200 and executing the method for correcting the error of the processing equipment.

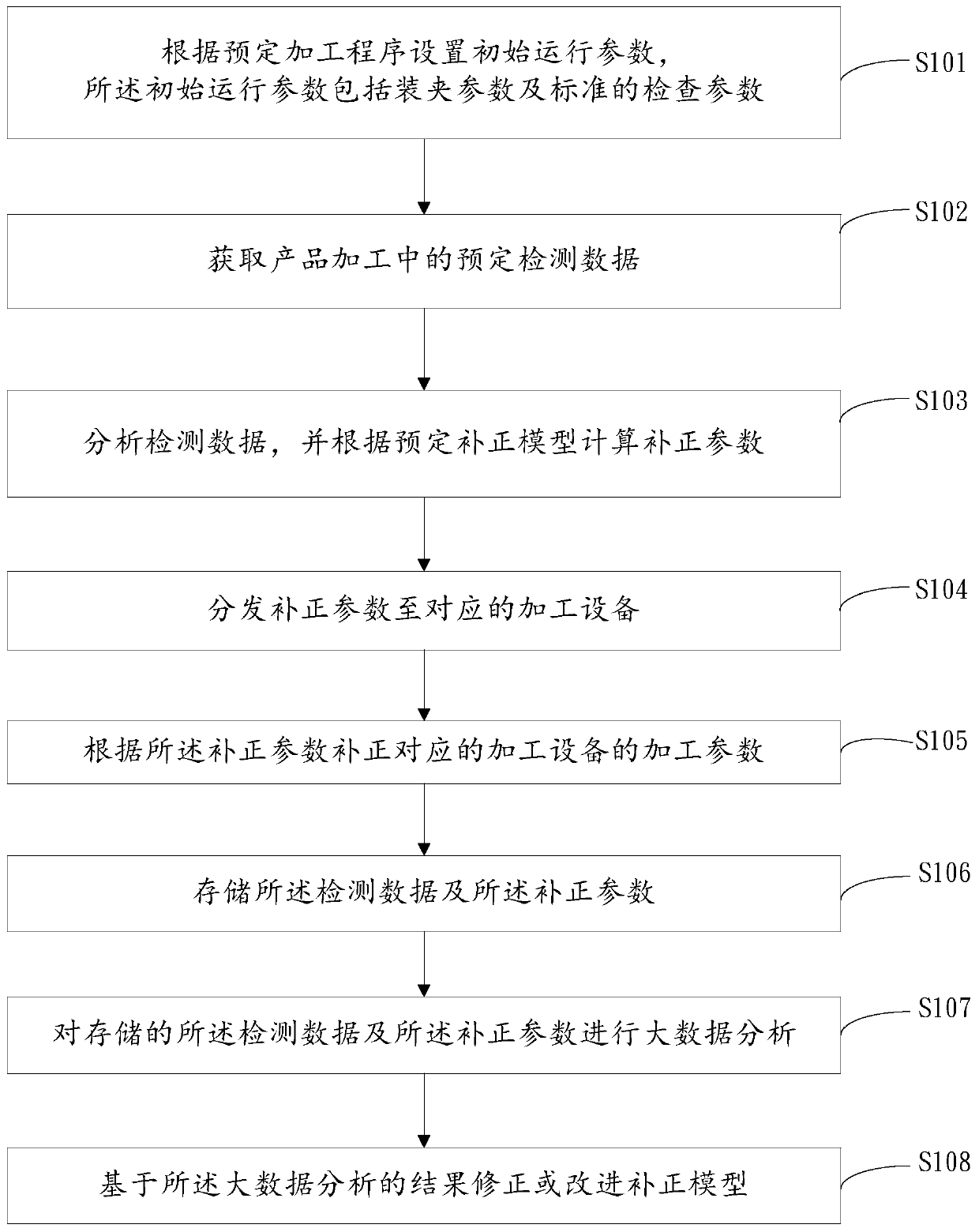

[0064] see also Figure 2 to Figure 7 As shown, the processing equipment error correction method is applied in the processing equipment error correction system 500, and includes the following steps.

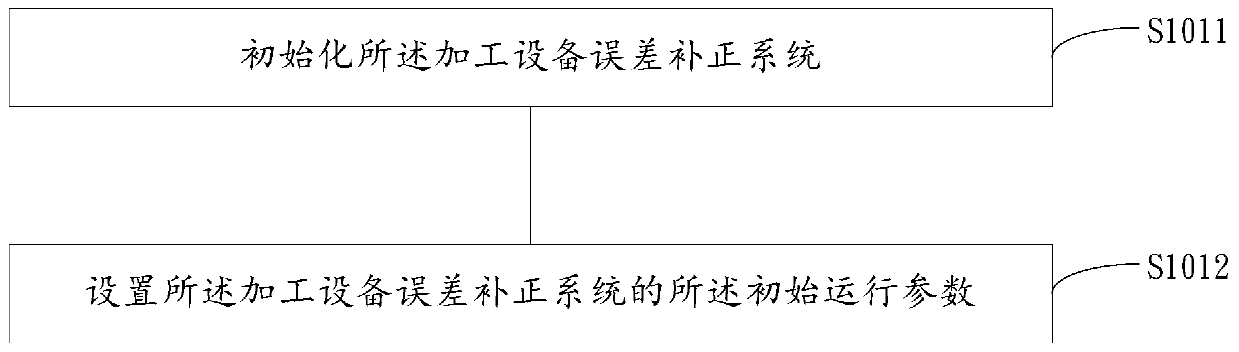

[0065] S101. Setting initial operating parameters according to a predetermined processing program. The initial operating parameters include clamping parameters and standard inspection parameters.

[0066] For example, when processing predetermined parts through processing equipment, such as CNC, the size parameters, shape and position tolerance parameters, clamping position and standard inspection parameters of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com