Automatic measuring device and measuring method for electrode paste height of submerged arc furnace

A technology of automatic measurement and submerged arc furnace, which is applied in measurement devices, optical devices, instruments, etc., can solve the problems of high safety risk, high labor intensity, and inaccurate manual measurement of electrode paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

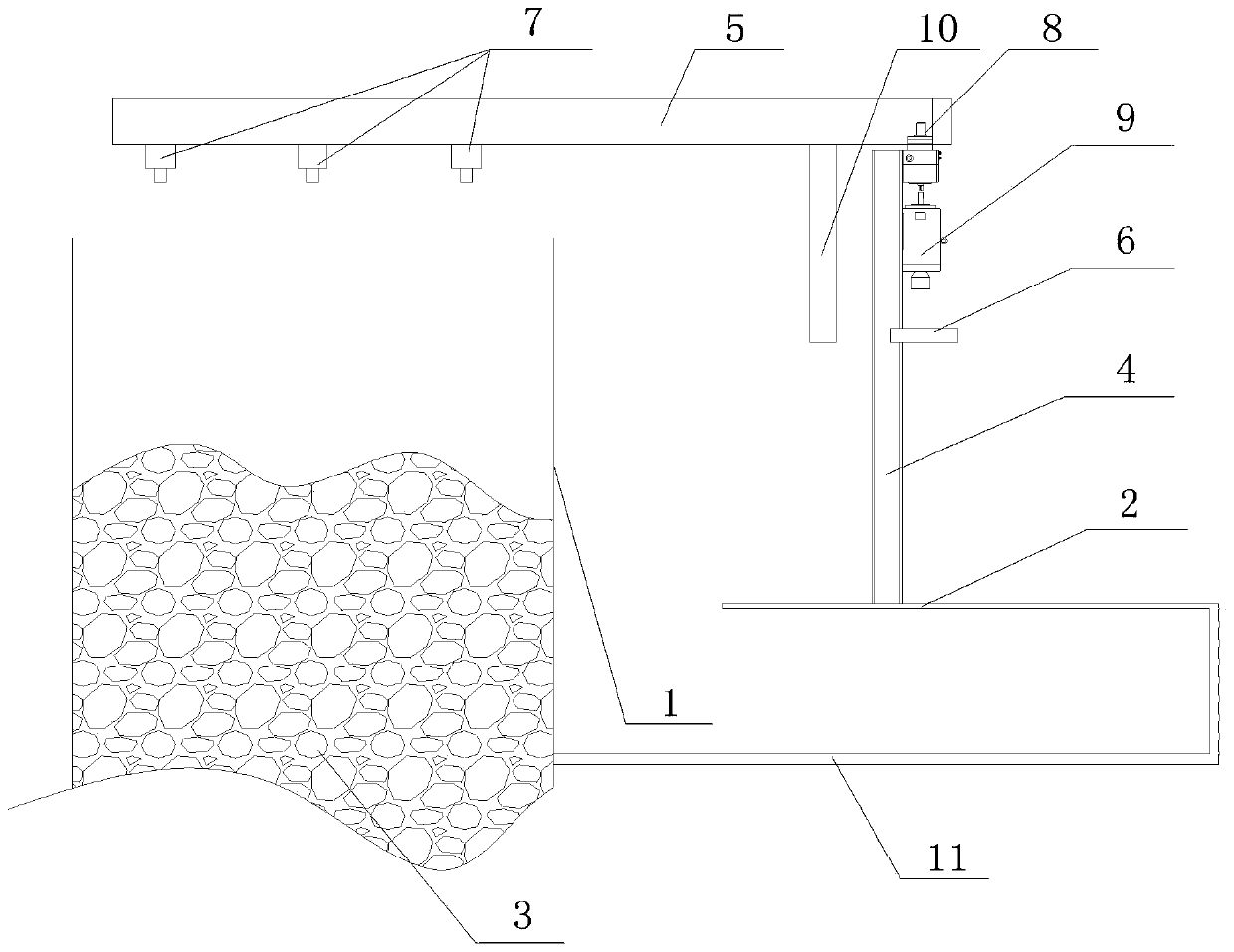

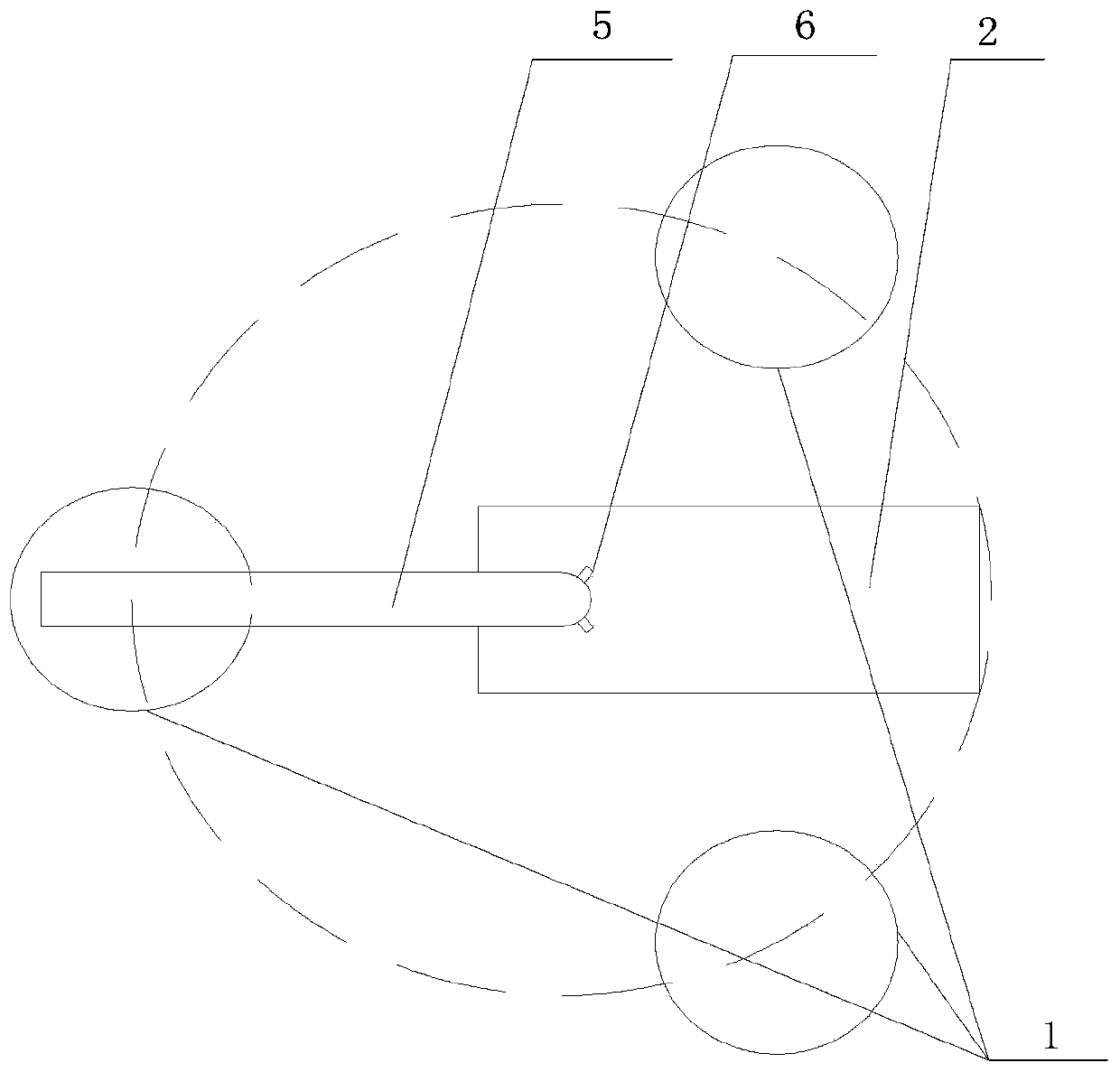

[0033] Such as Figure 1-2As shown, an automatic measuring device for the electrode paste height of a submerged arc furnace includes an electrode cylinder 1 and a five-layer platform 11 of the submerged arc furnace, and a paste measuring platform 2 is arranged between the electrode cylinders 1 on the five-layer platform 11 , the paste measuring platform 2 is provided with a fixed bracket 4, the middle part of the fixed bracket 4 is welded with a limit stopper 6, the upper part of the fixed bracket 4 is provided with a rotating motor 9, and the top of the rotating motor 9 is welded with The clamping fixed block 8 is fixedly equipped with a rotating parallel arm 5 on the clamping fixing block 8, and a downward vertical fixed stop rod 10 is welded on the rotating parallel arm 5. At the end of the rotating parallel arm 5 A laser rangefinder 7 is provided, and the electrode cylinder 1 is equipped with an electrode paste column 3 .

[0034] Specifically, the position of the fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com