A drum washing machine and its control method

A technology for drum washing machines and inner drums, which is applied to the control device of washing machines, other washing machines, washing machines with containers, etc. It can solve the problems of inability to detect the inner drum, affect the sealing effect of the door seal, increase the burden on the motor, etc., and achieve improved Health and user experience, reducing washing water consumption, and preventing dirt from adhering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

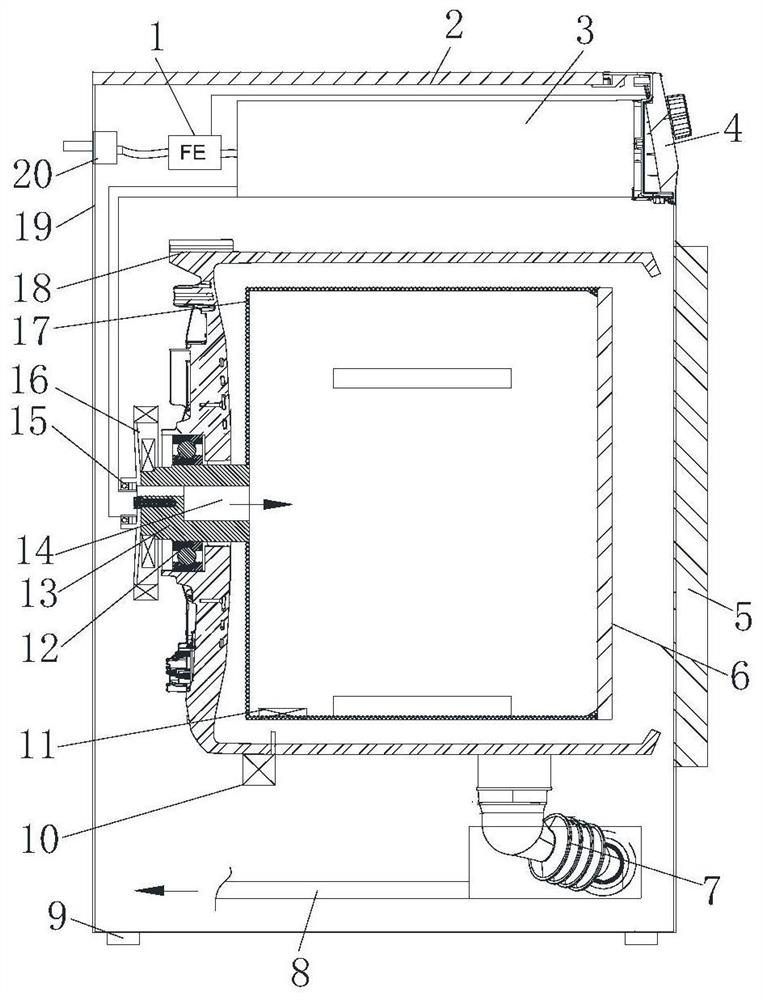

[0060] This embodiment mainly solves the problem of how to accurately determine the water intake of the non-porous inner drum drum washing machine, and the specific scheme is as follows:

[0061] A drum washing machine, comprising an inner cylinder 17 and a water inlet pipeline communicated with the inner cylinder 17, the inner cylinder 17 is a non-porous inner cylinder, and holds washing water when washing clothes, and the water inlet pipeline is provided for Flow sensor 1 that detects the flow of incoming water.

[0062] In this embodiment, a flow sensor 1 is installed on the water inlet pipeline to monitor the flow rate of the water inlet. When the set water inlet amount is reached, the water inlet valve 20 is closed to complete the water inlet. This embodiment adopts the flow sensor to solve the problem of water inflow according to the set water level of the non-porous inner drum washing machine, ensures the washing effect, has a simple structure and is convenient to opera...

Embodiment 2

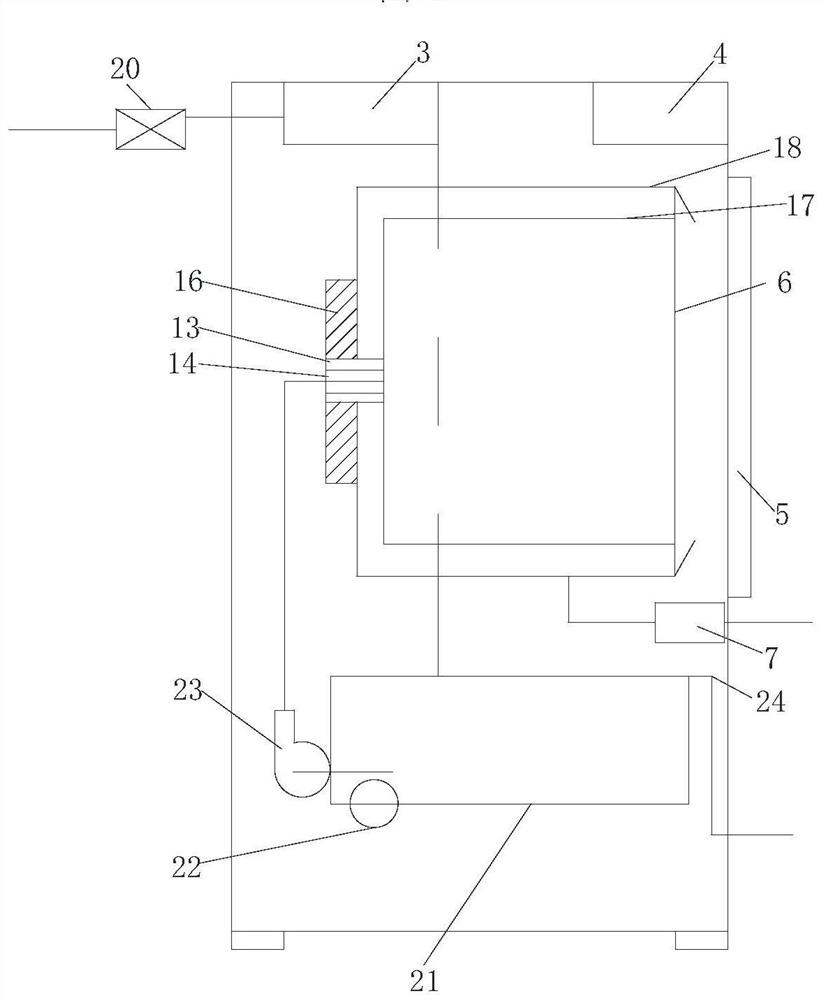

[0078] like Figure 2-Figure 4 As shown, a drum washing machine in this embodiment includes an inner tub 17 and a water inlet pipeline. The inner tub is a non-porous inner tub, which holds washing water when washing clothes, and also includes a quantity of water for measuring the water intake. The water inlet pipeline is connected with the water measuring device, and the water measuring device is communicated with the inner cylinder.

[0079] The drum washing machine of this embodiment is provided with a water measuring device, and before the water is fed into the inner tub 1, it enters the water measuring device for quantitative measurement, and determines the number of times the water measuring device measures water according to the set water level, thereby solving the problem of solving the problem. The non-porous inner drum washing machine ensures the washing effect according to the water inflow problem of the set water level, and has a simple structure and convenient oper...

Embodiment 3

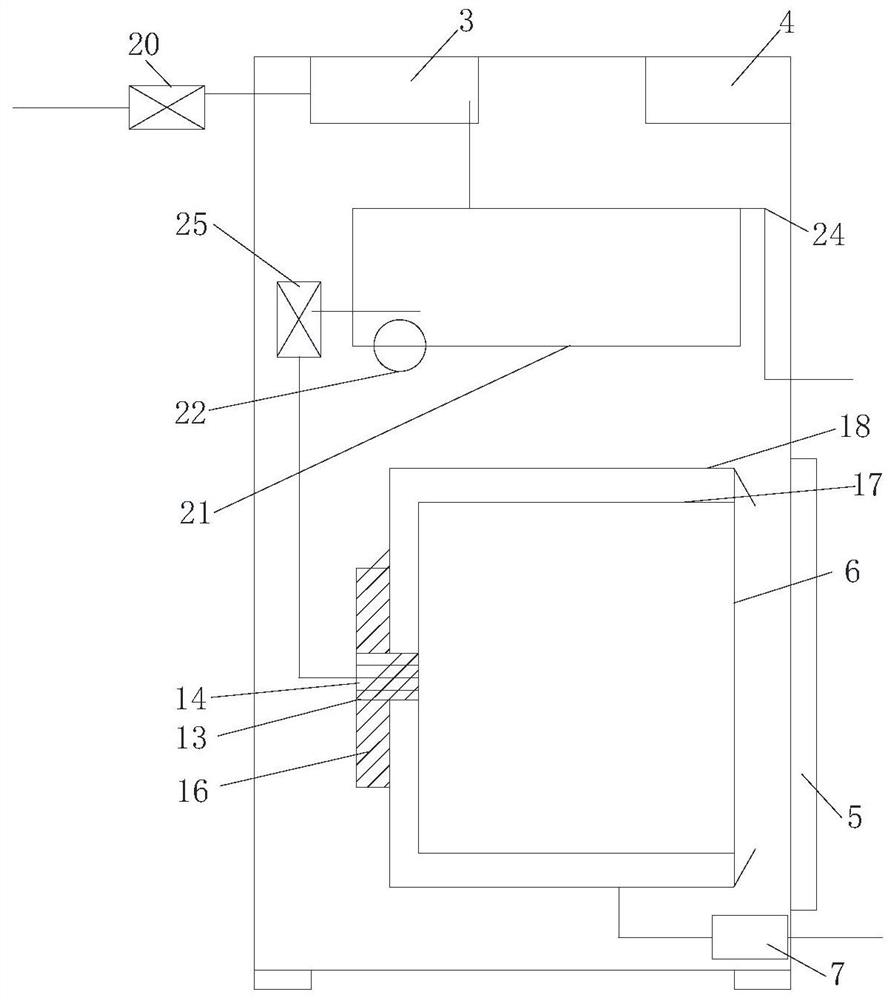

[0091] This embodiment mainly solves the problem of how to ensure the unbalanced air pressure in the airtight chamber of the non-porous inner drum washing machine. Specifically, the sudden water cutoff of the electromagnetic valve, especially the water disconnection of the water pipe network, forms a negative pressure, and the washing water in the airtight chamber is returned to the air. Wash to the pipe network; or there is gas inside, and it is difficult to enter the water.

[0092] like Figure 5-Figure 7 As shown, a drum washing machine in this embodiment includes an inner tub 17, the inner tub 17 is a non-porous inner tub, which holds washing water when washing clothes, and also includes a connection between the inner tub 17 and the external environment to balance the interior of the inner tub Air pressure balance mechanism.

[0093] When water enters, the gas in the sealed chamber of the inner cylinder can be overflowed through the equalizing mechanism under pressure to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com