Winding type optical coating device and method based on magnetron sputtering and electron gun evaporation

A magnetron sputtering coating and magnetron sputtering technology, applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc. Problems such as weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

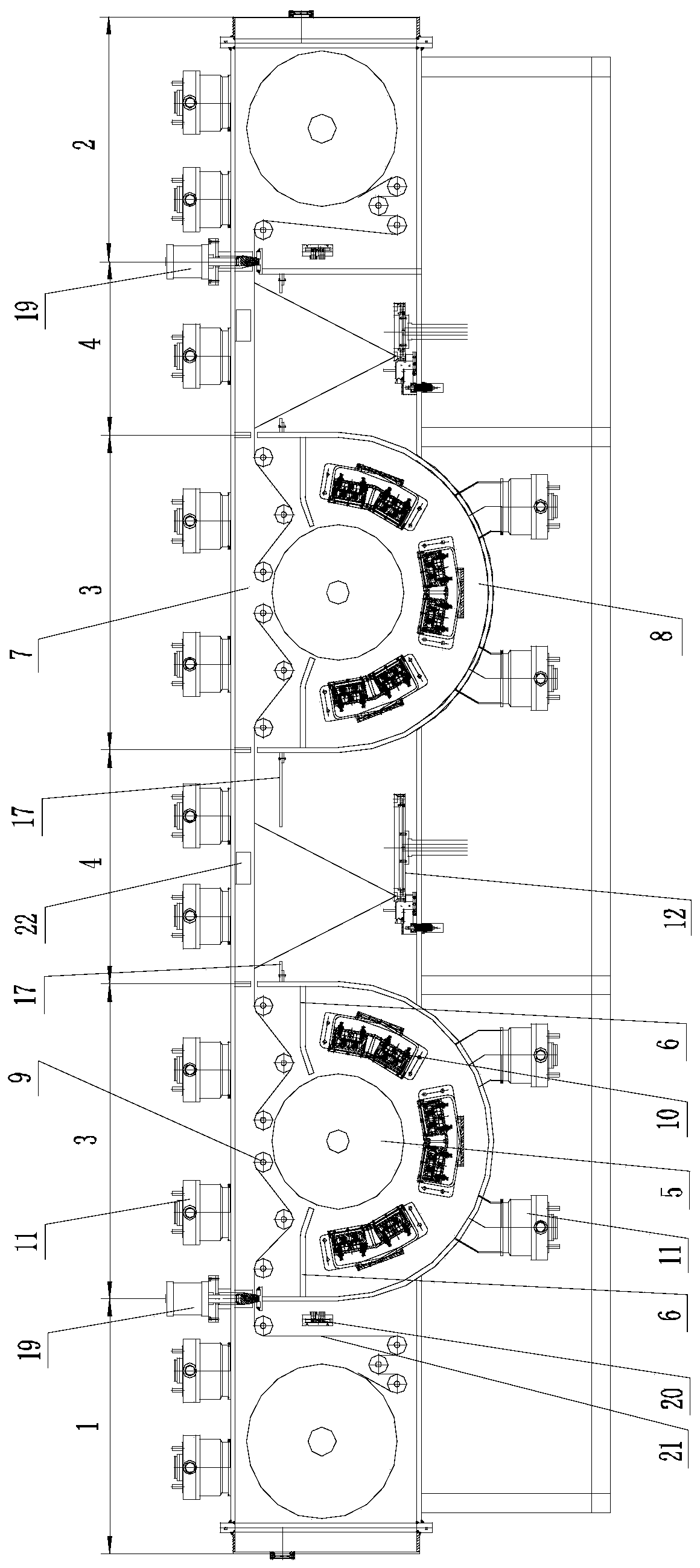

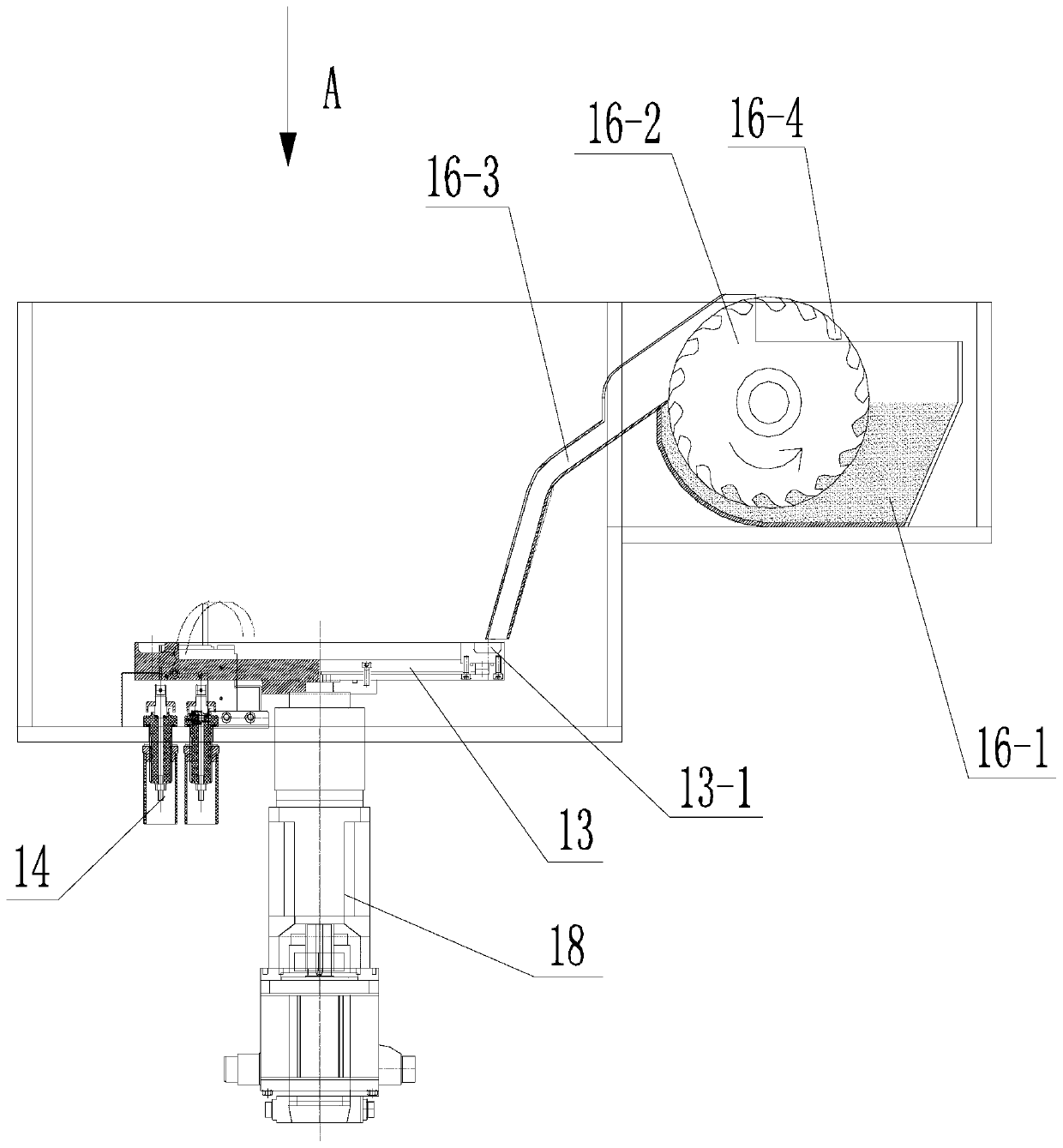

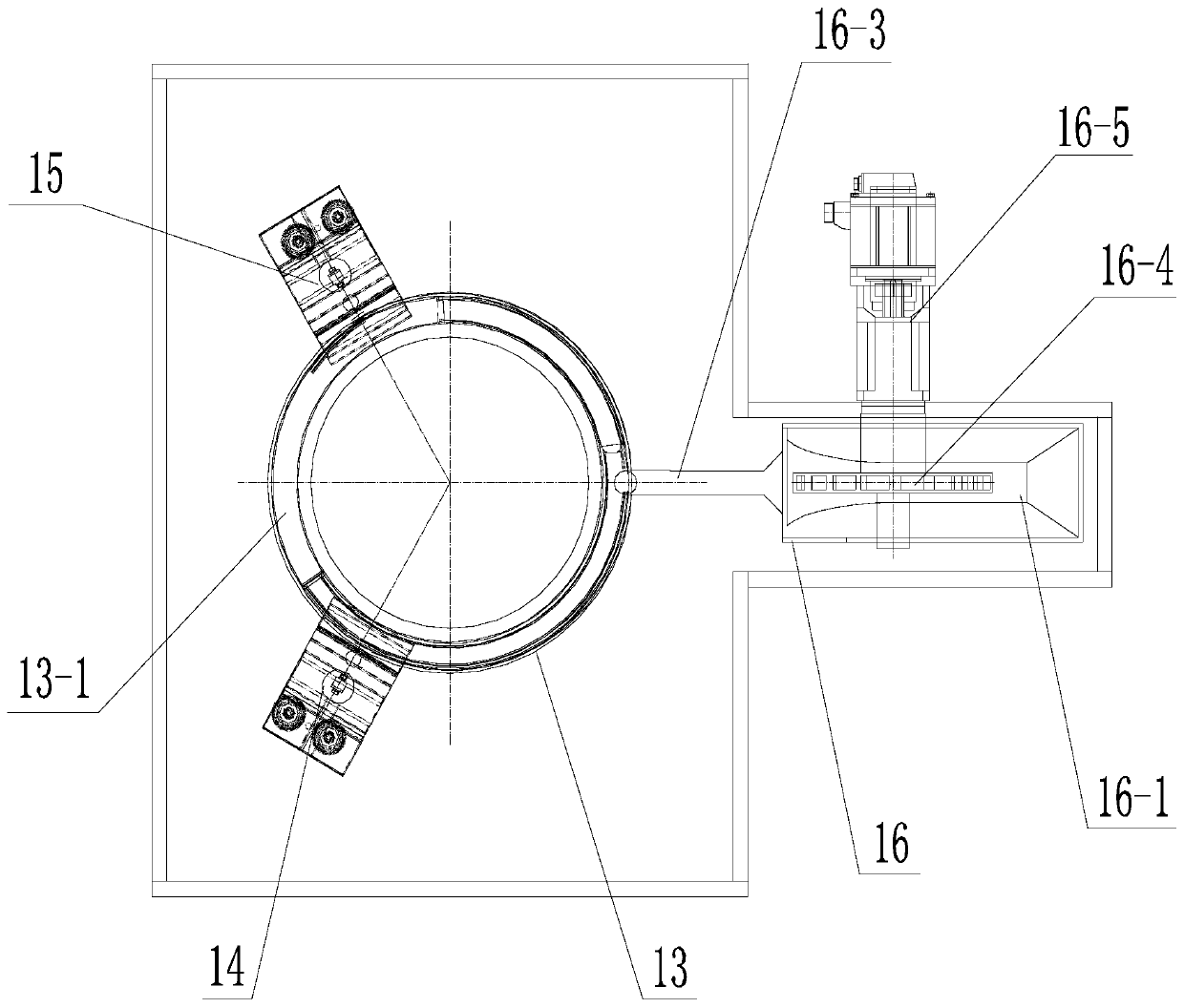

[0034] In this embodiment, a roll-to-roll optical coating device based on magnetron sputtering and electron gun evaporation, such as figure 1 As shown, it includes a plurality of vacuum chambers connected in a straight line. The two vacuum chambers at both ends are unwinding chamber 1 and winding chamber 2 respectively. Two magnetron sputtering chambers are alternately arranged between the unwinding chamber and the winding chamber. Coating chamber 3 and two electron guns evaporate coating chamber 4 . In the structure of the device, the number of magnetron sputtering coating chambers and electron gun evaporation coating chambers can be selected and installed according to the actual needs of different types of substrates. After each substrate passes through a magnetron sputtering coating chamber or an electron gun evaporation coating chamber A film layer can be formed, and the final film thickness is related to the number of magnetron sputtering coating chambers and electron gun...

Embodiment 2

[0041] In this embodiment, a winding-type optical coating method based on magnetron sputtering and electron gun evaporation, the silicon oxide optical film coating is realized through the winding-type optical coating device described in Embodiment 1, and the process is as follows:

[0042] (1) release the substrate 21 in the unwinding chamber;

[0043] (2) The substrate enters the magnetron sputtering coating chamber for magnetron sputtering coating treatment, forming a primary silicon oxide film layer on the surface of the substrate;

[0044] (3) The substrate enters the electron gun evaporation coating chamber for electron gun evaporation coating treatment to form a secondary silicon oxide film layer;

[0045] (4) Repeat steps (2) to (3) until the number of film layers meets the process requirements, and the coated substrate enters the winding chamber for winding.

[0046] In the above method, in the electron gun evaporation coating chamber, the base material is subjected t...

Embodiment 3

[0049] In this embodiment, a winding-type optical coating method based on magnetron sputtering and electron gun evaporation, the winding-type optical coating device described in Embodiment 1 is used to achieve silicon oxide / titanium oxide optical film coating, and the process is as follows:

[0050] (1) release the base material 21 in the roll chamber;

[0051] (2) The substrate enters the magnetron sputtering coating chamber for magnetron sputtering coating treatment, forming a primary silicon oxide film layer on the surface of the substrate;

[0052] (3) The substrate enters the electron gun evaporation coating chamber for electron gun evaporation coating treatment to form a secondary silicon oxide film layer;

[0053] (4) The base material enters the next magnetron sputtering coating chamber for magnetron sputtering coating treatment, while removing the silicon oxide with weak adhesion on the surface of the secondary silicon oxide film layer, a primary titanium oxide film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com